Device for preparing high-concentration ozone and recycling residual oxygen

A high-concentration, ozone technology, applied in the direction of ozone preparation, etc., can solve the problems of inconspicuous effect and inability to meet the needs of industrial production, and achieve the effect of wide application range, meeting the demand of high-concentration ozone, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

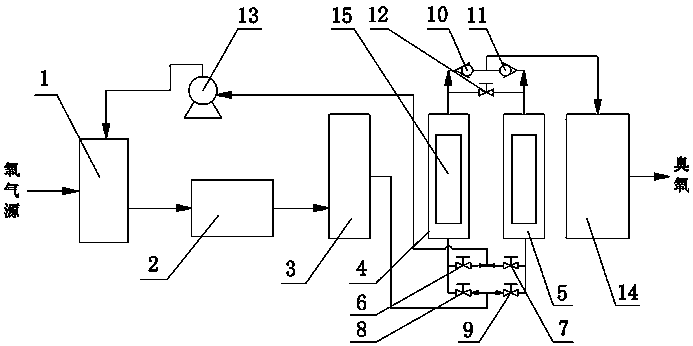

[0020] Embodiment 1: as figure 1 As shown, the equipment for producing high-concentration ozone and recovering and reusing residual oxygen includes oxygen buffer tank 1, ozone generator 2, mixed gas buffer tank 3, pressure swing adsorption tower A4, pressure swing adsorption tower B5, booster pump 13 and the ozone storage tank 14, the output end of the oxygen buffer tank 1 is connected with the input end of the ozone generator 2, the output end of the ozone generator 2 is connected with the input end of the mixed gas buffer tank 3, and the mixed gas buffer tank 3 is set in parallel PSA tower A4 and PSA tower B5 link to each other, PSA tower A4 and PSA tower B5 are all provided with oxygen outlet and ozone outlet respectively, the oxygen outlet of PSA tower A4 and PSA tower B5 are connected with A booster pump 13 is arranged between the oxygen buffer tanks 1, and the ozone outlets of the pressure swing adsorption tower A4 and the pressure swing adsorption tower B5 are connected...

Embodiment 2

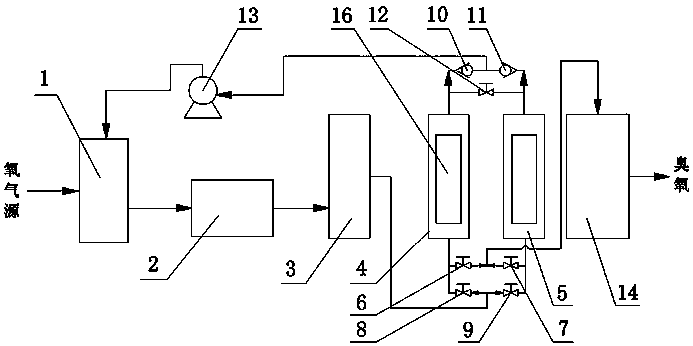

[0022] Embodiment 2: as figure 2 As shown, the equipment for producing high-concentration ozone and recovering and reusing residual oxygen includes oxygen buffer tank 1, ozone generator 2, mixed gas buffer tank 3, pressure swing adsorption tower A4, pressure swing adsorption tower B5, booster pump 13 and the ozone storage tank 14, the output end of the oxygen buffer tank 1 is connected with the input end of the ozone generator 2, the output end of the ozone generator 2 is connected with the input end of the mixed gas buffer tank 3, and the mixed gas buffer tank 3 is set in parallel PSA tower A4 and PSA tower B5 link to each other, PSA tower A4 and PSA tower B5 are all provided with oxygen outlet and ozone outlet respectively, the oxygen outlet of PSA tower A4 and PSA tower B5 are connected with A booster pump 13 is arranged between the oxygen buffer tanks 1, and the ozone outlets of the pressure swing adsorption tower A4 and the pressure swing adsorption tower B5 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com