Side-blown continuous smelting process and device for electronic scrap

An electronic waste and process technology, applied in the field of side blowing continuous smelting process and device, can solve the problems of inability to realize the need for smelting and blowing reaction zones, and inability to continuously smelt electronic waste, etc., to save fuel consumption, improve thermodynamics, heat Less leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

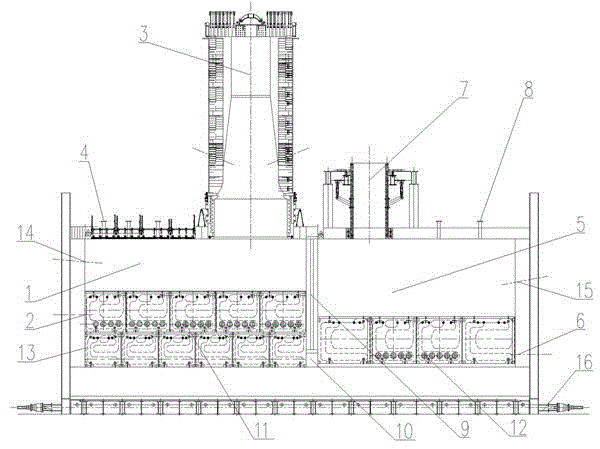

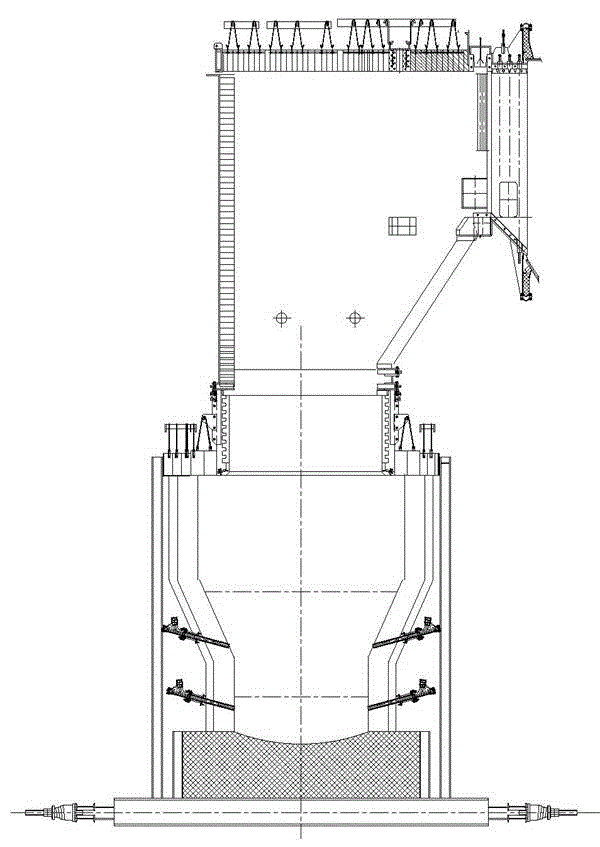

[0009] The present invention will be further described below in conjunction with accompanying drawing:

[0010] A side-blowing continuous smelting process for electronic scraps, comprising the following steps: feeding electronic scraps of a certain size, copper-rich materials and flux into a sedimentation tank in the smelting zone through a feeding port on the top of the smelting zone, and falling on the surface of the smelting slag; The air eyes on both sides of the furnace at the height of the slag layer in the sedimentation tank in the smelting area send oxygen-rich gas into the smelting slag layer to form agitation, and the electronic waste is involved in the slag layer, and various components contained in the electronic waste react with oxygen and flux. reaction, forming black copper and slag. Among them, the black copper drops into the black copper layer at the bottom of the furnace due to the density, and the slag remains in the smelting slag layer, and the discharge po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com