High-altitude hoisting construction method of super-heavy steel truss on transfer floor

A construction method and technology of steel trusses, which are applied in construction, building structure, processing of building materials, etc., can solve problems such as very high requirements on the accuracy of hoisting positions, inability to make full use of equipment, and difficulty in entering the site for construction, and achieve flexible arrangements. The effect of construction progress, shortening construction period and saving engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

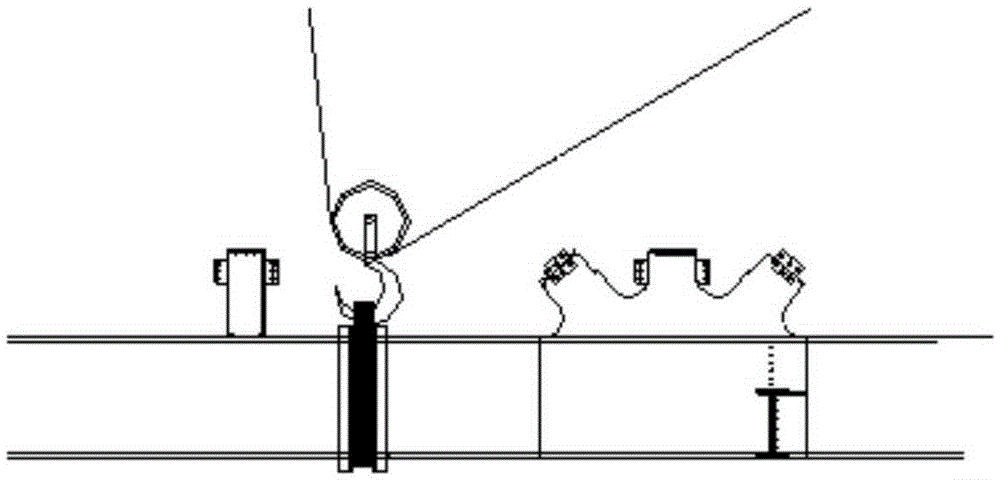

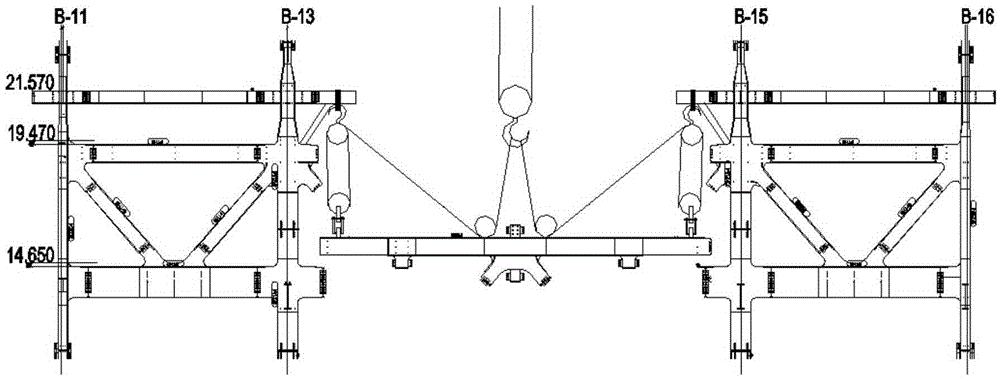

[0023] In order to ensure construction safety, this method needs to review some technical data before the specific implementation: (1) Review the hoisting capacity of steel components and hoisting cars to the floor. (2) Check the bearing capacity of the floor when the steel members slide on the floor, and ask the design for approval. (3) Selection and calculation of steel wire rope; (4) Selection and calculation of pulley block. (5) Calculation of the bearing capacity of the top corbel. (6) Check the lifting capacity of the tower crane at this part through the pulley block.

[0024] Such as Figure 1-Figure 4 As shown, the high-altitude hoisting construction method of the super-heavy steel truss of the transfer layer of the present invention specifically includes the following steps:

[0025] (1) On-site installation of tower cranes that meet normal structural construction requirements.

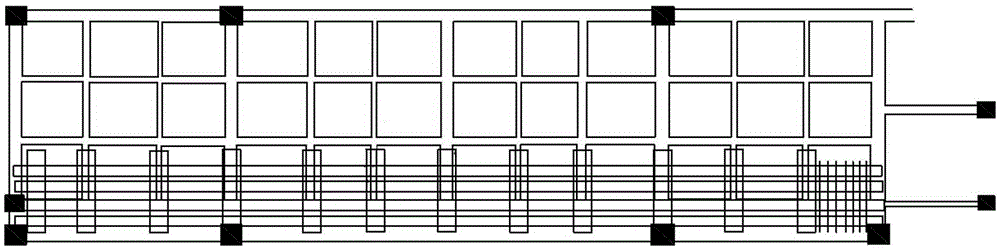

[0026] (2) Lay track on the floor of the hoisting area of the transfer floor; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com