Construction method and structure for strengthening deep weak structural surface of large rock slope

A technology for weak structural surfaces and rock slopes, which is applied to the construction of strengthening the deep weak structural surfaces of large rock slopes, strengthening construction structures, and strengthening the construction structures of large deep rock slopes with weak structural surfaces, can solve difficult problems Reinforcement of weak structural surfaces, long construction period, large investment and other issues, to achieve the effect of solving temperature control problems, reducing heat dissipation time, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

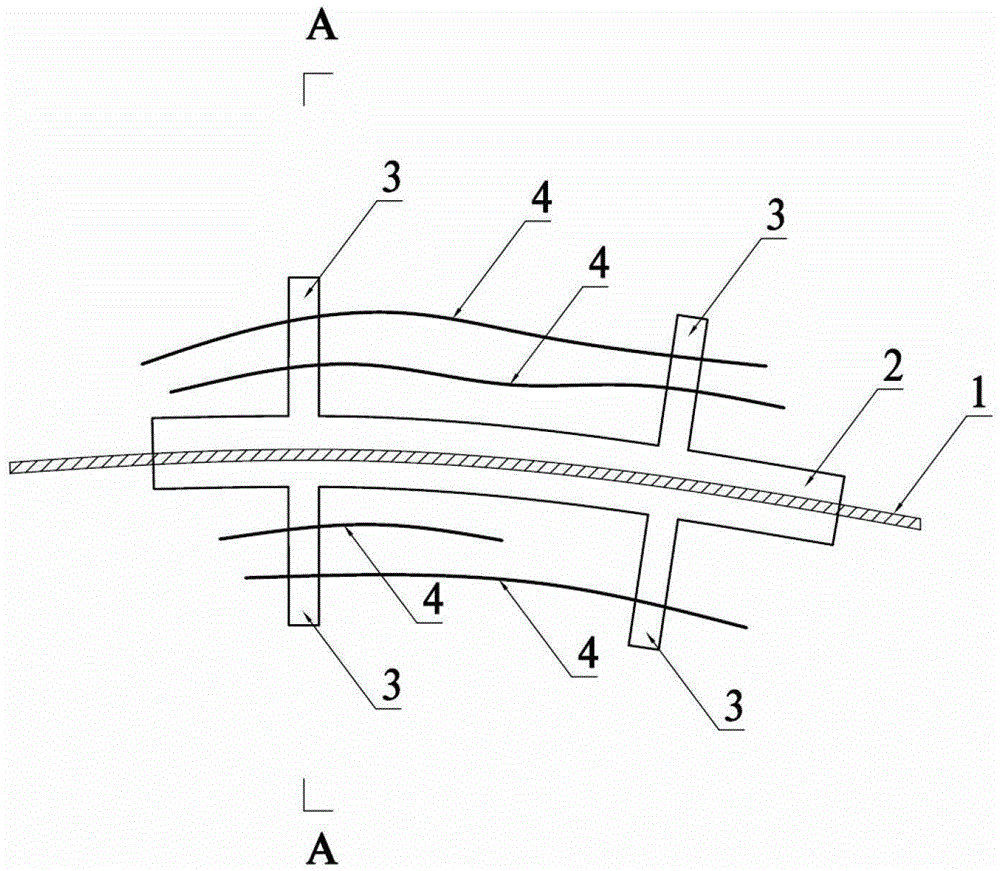

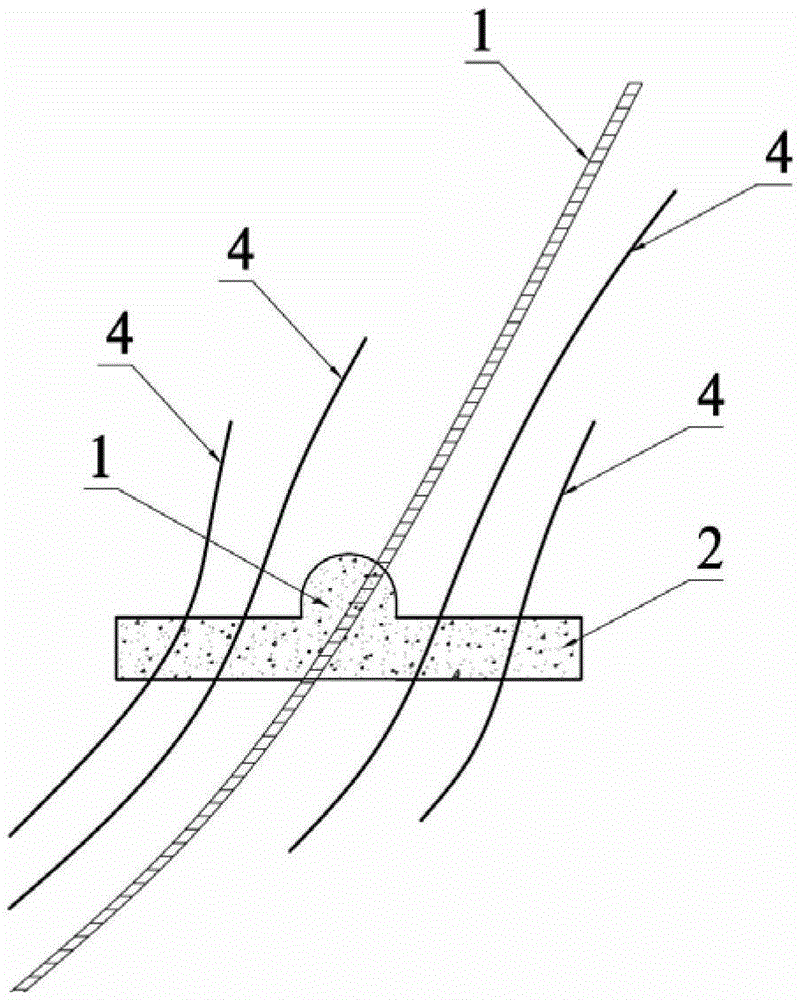

[0048] Such as figure 1 and figure 2 As shown, there is a deep weak structural plane 1 along the slope direction in a large rock slope, which controls the overall stability of the slope. Many associated cracks 4 are developed on the inner and outer sides of the deep weak structural plane 1 . The steps of strengthening the deep weak structural surface 1 are as follows:

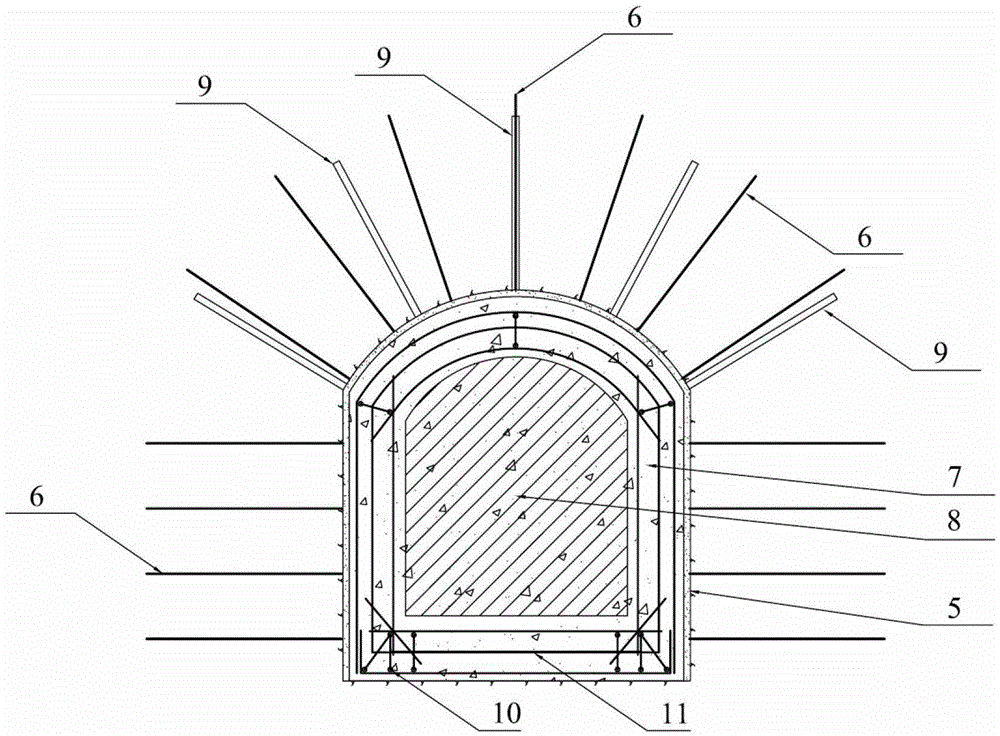

[0049] 1. Excavate the long and horizontally arranged main tunnel 2 along the direction of the deep weak structural surface 1. The section of the main tunnel 2 adopts the shape of a city gate, and the size is 8m wide x 9m high. Combined with actual geological conditions, such as image 3 As shown, the main tunnel 2 is initially supported by hanging nets, shotcrete 5, and bolts 6. Drainage holes 9 are drilled in the range of the top arch, and the depth of the holes is 4m.

[0050] 2. To excavate the branch tunnel 3, the general operation is to excavate the branch tunnel 3 after the main tunnel 2 is tempora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com