Multi-channel galvanic corrosion test system and method based on micro electrode array

A technology of micro-electrode array and galvanic corrosion, which is applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve problems such as the degree of automation to be improved, the testing time is long, and the use is inconvenient, and flexible reconfiguration can be achieved. , the effect of improved synchronization and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

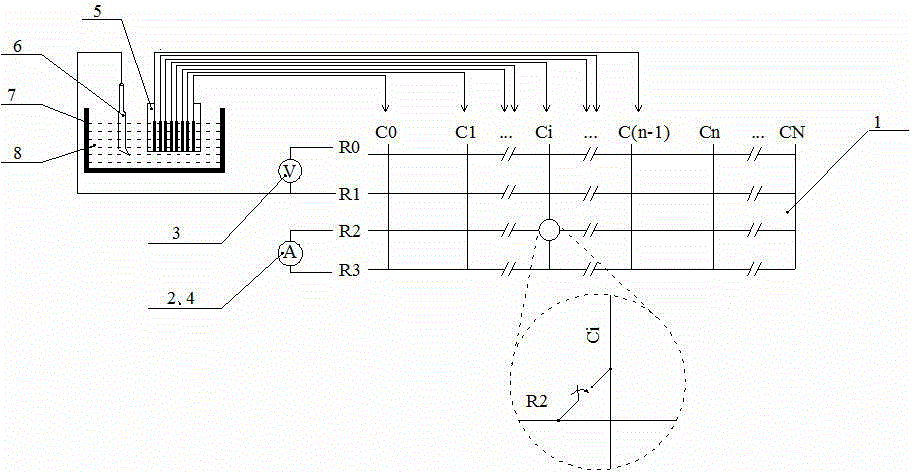

[0017] 1) Independent main control multi-channel galvanic corrosion test system

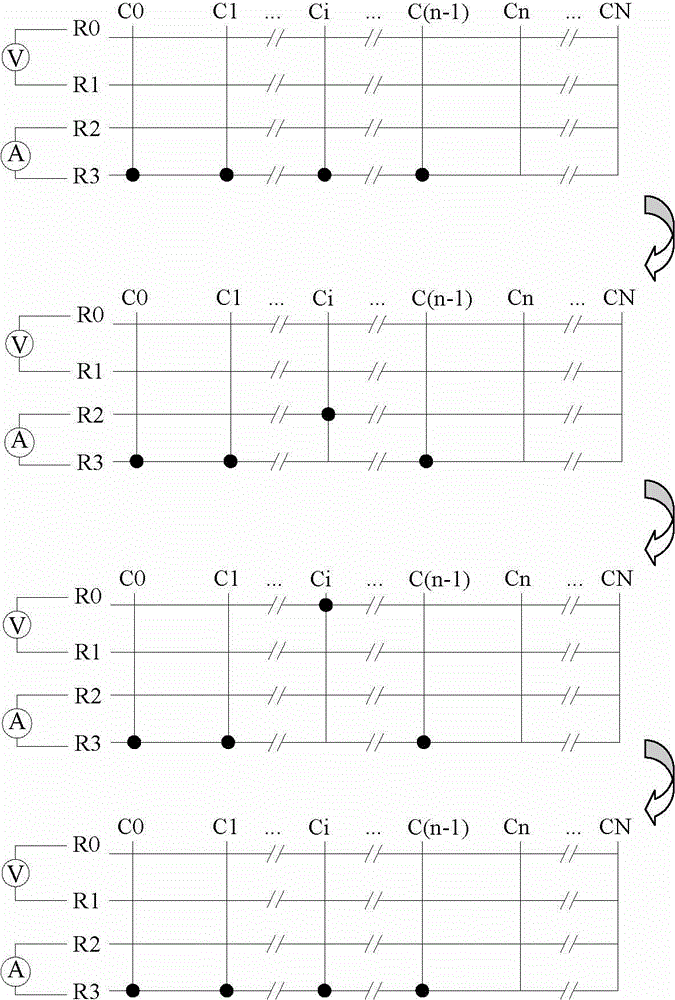

[0018] Under the premise of not losing the test accuracy, the test system adopts the current measurement and potential measurement of each microelectrode in the microelectrode array and the high-speed switching test method for the measurement of all microelectrodes to be tested, so that the same microelectrode can be obtained. The galvanic corrosion data with high synchronization between the current measurement and the potential measurement of different microelectrodes, that is, the electrochemical distribution information of different microregions of the microelectrode array.

[0019] The hardware test system includes: chassis NI PXI-1042Q, embedded controller NI PXI-8108, portable display and keyboard accessory NI PMA-1115, high-speed matrix switch NI PXI-2535, 2 digital multimeters NI PXI-4071 and weak current Amplifier NI PXI-4022.

[0020] NI PXI-1042Q is a chassis that can integrate NI PXI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com