Disconnected and staggered air-cooling radiator

A heat sink and air-cooled technology, which is applied in the field of cooling devices for auxiliary power modules of electric locomotives, can solve the problems of demanding heat sink requirements and reduced local heat dissipation capacity, and achieve the effects of improving heat dissipation capacity decline, reducing processing difficulty, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

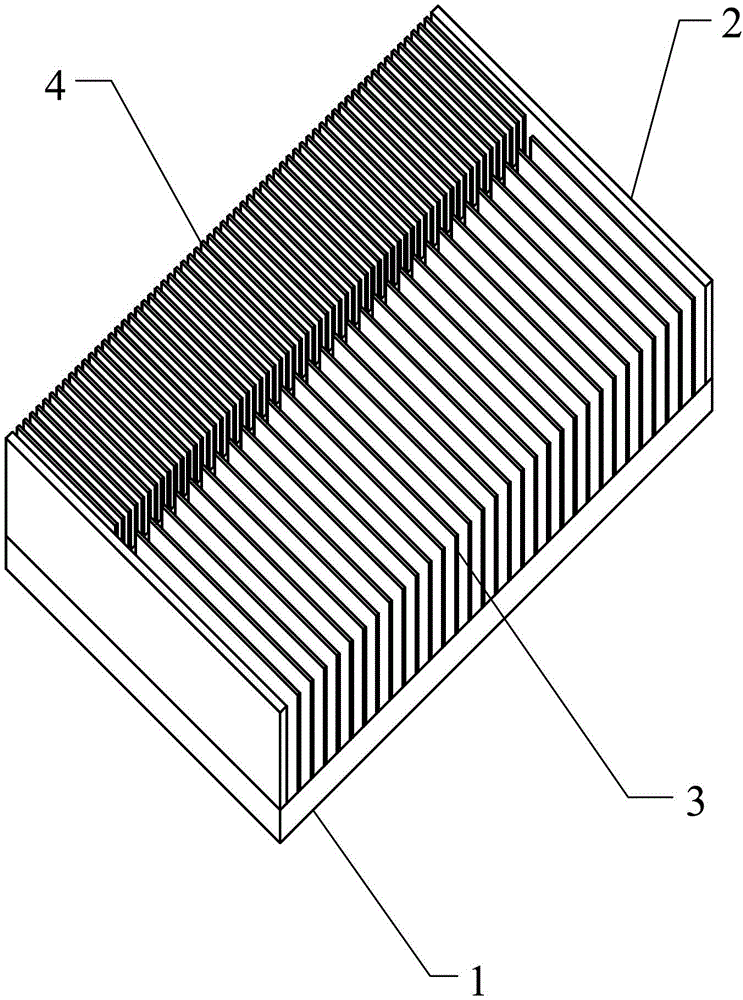

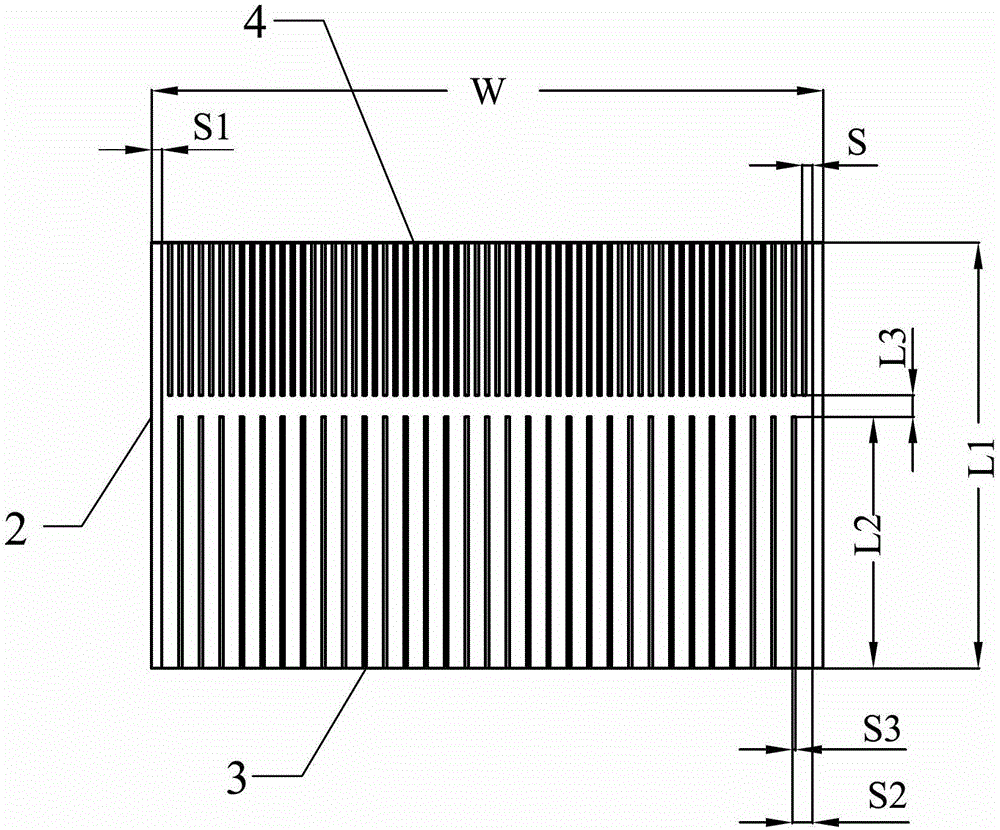

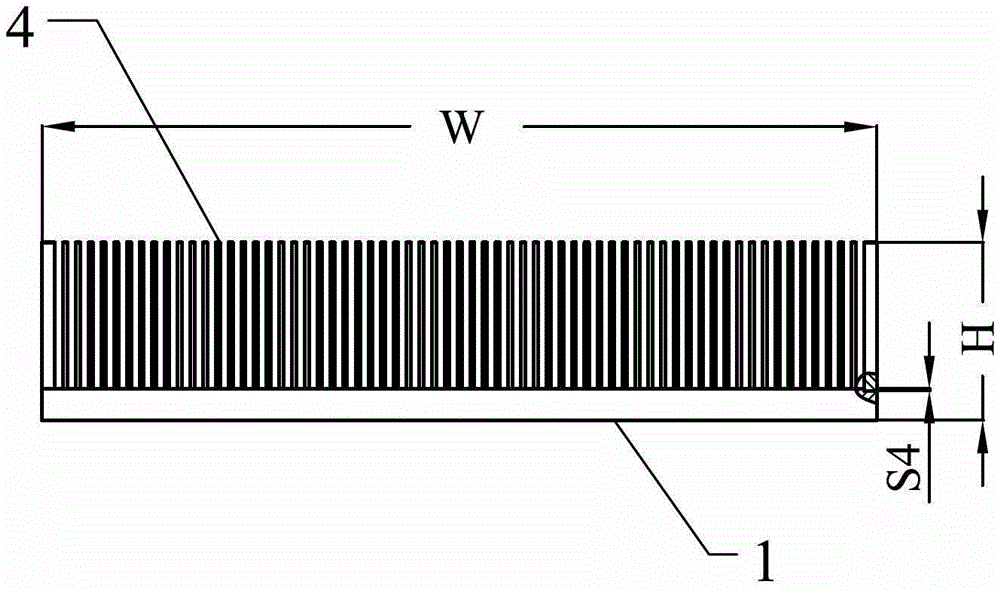

[0029] Such as figure 1 As shown, a discontinuous misplaced air-cooled radiator includes a base plate 1, a baffle plate 2 and a fin group, and the fin group includes a wide-pitch fin group 3 and a narrow-pitch fin group 4, forming the wide The fins of the pitch fin group 3 and the narrow pitch fin group 4 are straight fins or corrugated fins with a rectangular cross section. When the fins are corrugated fins (such as Figure 4 shown), after the corrugated fin is fixed to the substrate 1, the wavelength direction of the corrugated fin is parallel to or perpendicular to the flow direction of the air, and the wavelength λ of the corrugated fin is 10- 20mm.

[0030] In this example, the given fins are straight fins (such as figure 2 shown), the thickness of the fins is S3=2mm; the tooth pitch of the wide-pitch fin group 3 is S2, S2=12mm; the tooth pitch of the narrow-pitch fin group 4 is S, S=6mm; The fin width of the wide pitch fin group 3 is L2, L2=200mm; the length of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com