Inorganic mesoporous materials with chiral nematic structures and preparation method thereof

An inorganic material, chiral technology, applied in inorganic chemistry, liquid crystal materials, chemical instruments and methods, etc., can solve the problem of no obvious evidence of long-range chiral order, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0065] Synthesis of Silica / NCC Composite:

[0066] Add 0.600 mL of tetraethoxysilane (TEOS) to 10 mL of freshly sonicated 3% suspension of NCC in water. The mixture was stirred at 60 °C until a homogeneous mixture was obtained (~3 h), indicating complete hydrolysis of TEOS. Allow to cool to room temperature and drop-cast onto polypropylene Petri dishes. After slow evaporation at room temperature, a blue iridescent free-standing film (490 mg) was obtained. TGA curves and IR data are shown in Figure 17 and Figure 18 middle.

[0067] Calcination:

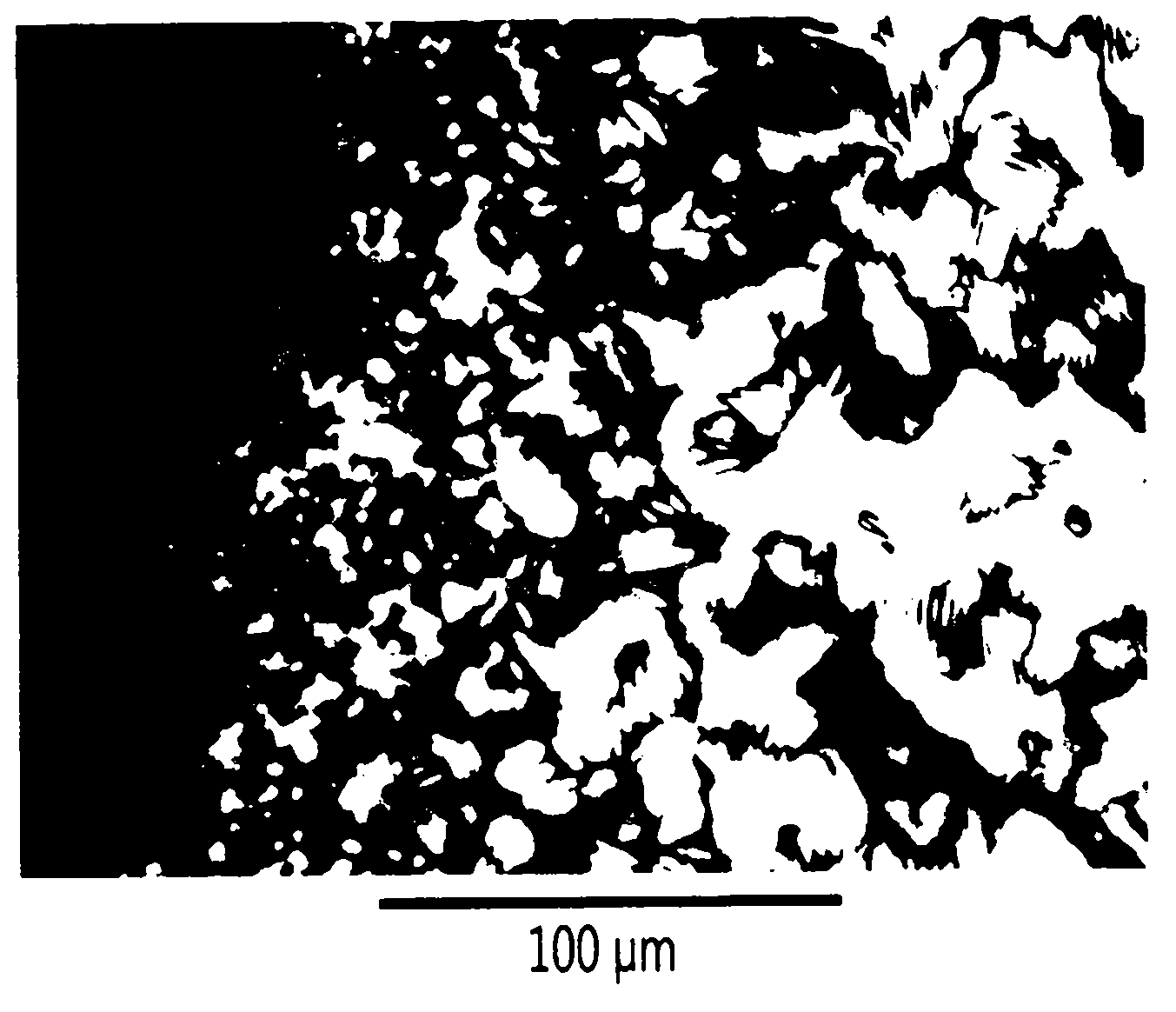

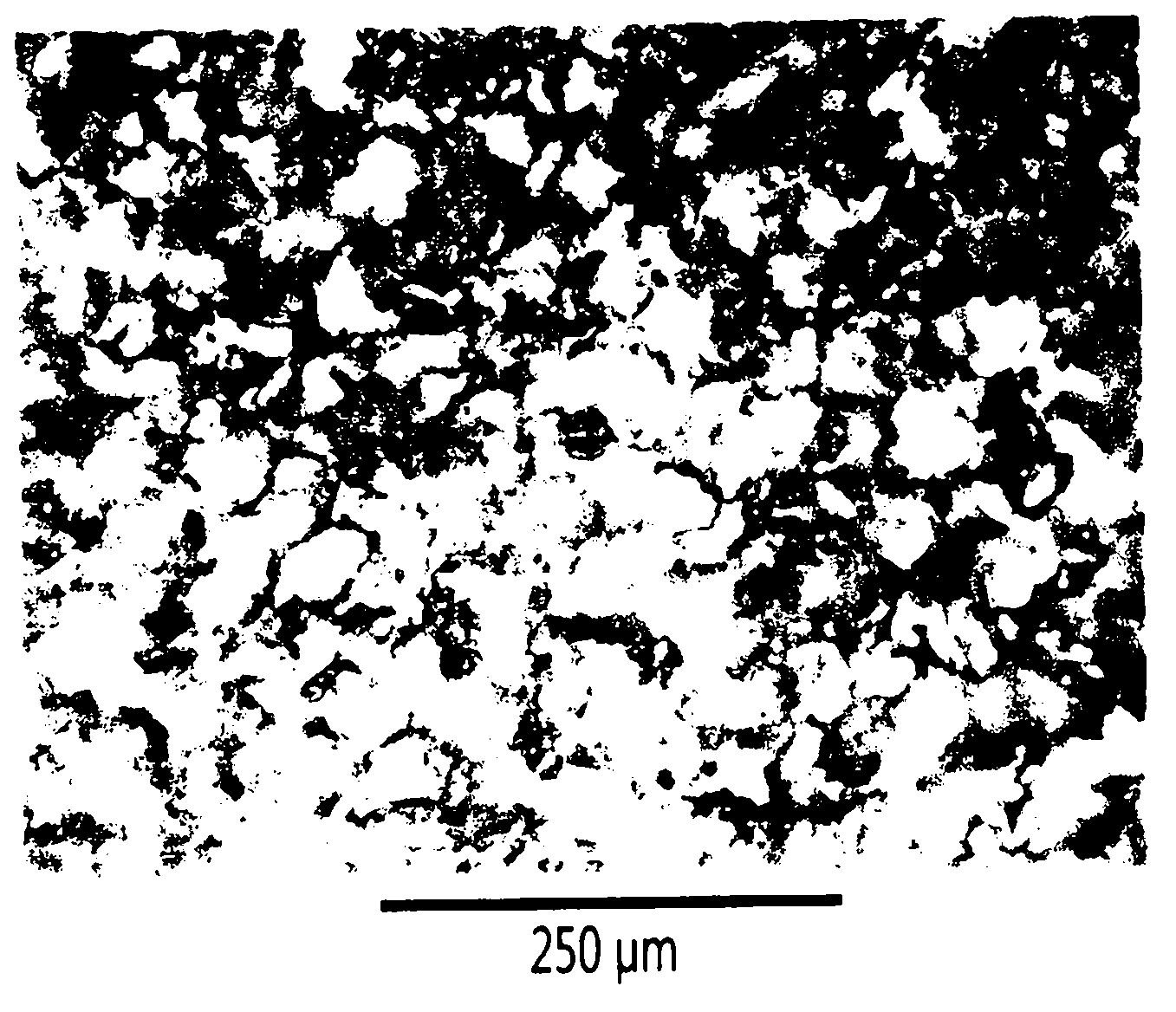

[0068] 300 mg of composite film was heated to 540°C at a rate of 120°C / h and maintained at 540°C for 6 hours under flowing air. After slow cooling to room temperature, 100 mg of a free-standing colorless film could be recovered. The IR spectrogram of the sample confirmed that the NCC was completely removed ( Figure 19). Nitrogen adsorption measurements show 720m 2 / g BET surface area ( Figure 13 ), and SEM images reveale...

preparation example 2

[0070] Synthesis of Silica / NCC Composite:

[0071] 1.950 mL of TEOS was added to 10 mL of freshly sonicated 3% NCC suspension in water, and the mixture was stirred at 60 °C until a homogeneous mixture was obtained (~3 h), indicating complete hydrolysis of TEOS. Allow to cool to room temperature and drop-cast onto polypropylene Petri dishes. After slow evaporation at room temperature, a free-standing red iridescent film was obtained.

[0072] Calcination:

[0073] 300 mg of composite film was heated to 540°C at a rate of 120°C / h and maintained at 540°C for 6 hours under flowing air. After slow cooling to room temperature, 180 mg of a free-standing blue-green film were recovered. IR confirmed complete removal of NCC, and nitrogen adsorption measurements showed 408m 2 / g of BET surface area.

preparation example 3

[0075] Synthesis of Silica / NCC Composite:

[0076] Add 0.750 mL of TEOS to 6 mL of freshly sonicated 2% NCC suspension in water. The mixture was stirred at 60 °C until a homogeneous mixture was obtained (~3 h), indicating complete hydrolysis of TEOS. Allow to cool to room temperature and drop cast onto polypropylene Petri dishes. After slow evaporation at room temperature, a colorless film was obtained.

[0077] Calcination:

[0078] 300 mg of composite film was heated to 540°C at a rate of 120°C / h and maintained at 540°C for 6 hours under flowing air. After slow cooling to room temperature, 195 mg of a free-standing red film were recovered. The IR spectrum of the sample confirmed complete removal of NCC.

[0079] Nitrogen adsorption measurements show 240m 2 / g BET surface area, and SEM images show a structure consistent with the chiral nematic organization ( Figure 9 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com