Wheat type concentrated feed for layers during egg production peak hours and preparation method thereof

A technology of concentrated feed during the peak egg production period, which is applied in the field of concentrated feed and its preparation during the peak egg production period of wheat-type laying hens. It can solve the problems of difficult formula control, large nutritional index differences, and impact on egg production, so as to save feed cost, solve digestion and absorption problems, and improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Concentrated feed for wheat-type laying hens during the peak laying period, the composition of raw materials in parts by weight is as follows:

[0044] 38 parts of soybean meal, 8 parts of cotton meal, 2.5 parts of oil, 5 parts of corn gluten meal, 9.5 parts of corn syrup protein, 9.7 parts of sprayed bran, 19.8 parts of 12 mesh stone powder, 3.1 parts of 18 mesh stone powder, 1.6 parts of calcium hydrogen phosphate, 0.25 parts of lysine, 0.15 parts of methionine, 0.00125 parts of biotin, 0.11 parts of compound multidimensional, 0.35 parts of compound trace elements, 0.15 parts of microecology, 0.09 parts of phytase, 0.0385 parts of xylanase, 0.00125 parts of Jialisu red , 0.0037 parts of Jia Li Su Huang, 0.8 parts of table salt, 0.0233 parts of antioxidants, 0.382 parts of baking soda, 0.38 parts of Yuanming powder, and 0.07 parts of betaine.

[0045] The preparation method is as follows: taking each raw material according to the proportion, then crushing the raw mater...

Embodiment 2

[0048] Concentrated feed for wheat-type laying hens during the peak laying period, the weight percentage of raw materials is as follows:

[0049] 35 parts of soybean meal, 9.5 parts of cotton meal, 2.3 parts of oil, 6 parts of corn gluten powder, 9.8 parts of corn steep liquor protein, 10.2 parts of sprayed bran, 20.9 parts of 12 mesh stone powder, 2 parts of 18 mesh stone powder, 1.5 parts of calcium hydrogen phosphate, 0.27 parts of lysine, 0.13 parts of methionine, 0.00125 parts of biotin, 0.11 parts of compound multidimensional, 0.35 parts of compound trace elements, 0.15 parts of microecology, 0.09 parts of phytase, 0.0385 parts of xylanase, 0.00125 parts of Jialisu red , 0.0037 parts of Jia Li Su Huang, 0.8 parts of table salt, 0.0233 parts of antioxidants, 0.382 parts of baking soda, 0.38 parts of Yuan Mingfen, and 0.07 parts of betaine.

[0050] Preparation method, usage are the same as embodiment 1.

Embodiment 3

[0052] Concentrated feed for wheat-type laying hens during the peak laying period, the weight percentage of raw materials is as follows:

[0053] 40 parts of soybean meal, 8.1 parts of cotton meal, 2.6 parts of oil, 4 parts of corn gluten powder, 9 parts of corn steep liquor protein, 9 parts of sprayed bran, 18.7 parts of 12 mesh stone powder, 4.1 parts of 18 mesh stone powder, 1.7 parts of calcium hydrogen phosphate, 0.23 parts of lysine, 0.17 parts of methionine, 0.00125 parts of biotin, 0.11 parts of compound multidimensional, 0.35 parts of compound trace elements, 0.15 parts of microecology, 0.09 parts of phytase, 0.0385 parts of xylanase, 0.00125 parts of Jialisu red , 0.0037 parts of Jia Li Su Huang, 0.8 parts of table salt, 0.0233 parts of antioxidants, 0.382 parts of baking soda, 0.38 parts of Yuan Mingfen, and 0.07 parts of betaine.

[0054] Preparation method, usage are the same as embodiment 1.

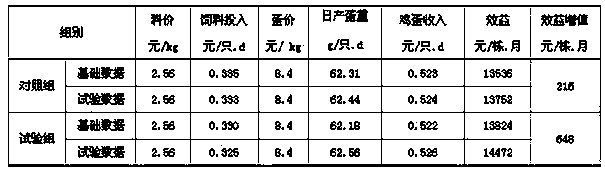

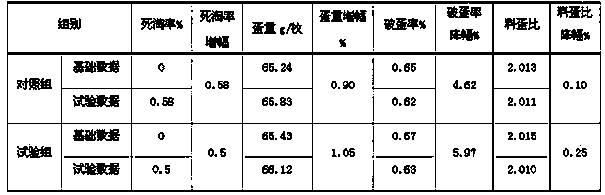

[0055] Effect example

[0056] In order to verify the feeding effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com