Automatic flushing method and device for fiber washing sieve

An automatic flushing and fiber technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of fiber washing screen clogging, etc., and achieve improved operating hours, good flushing effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

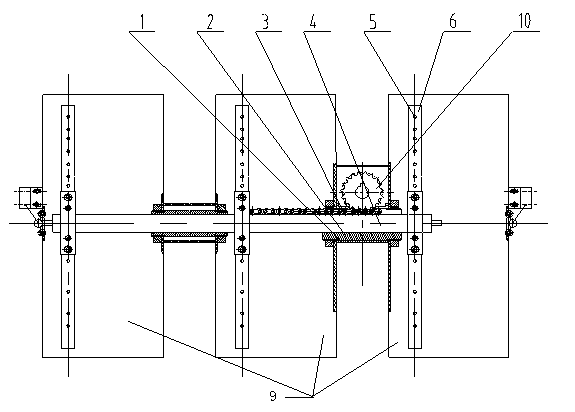

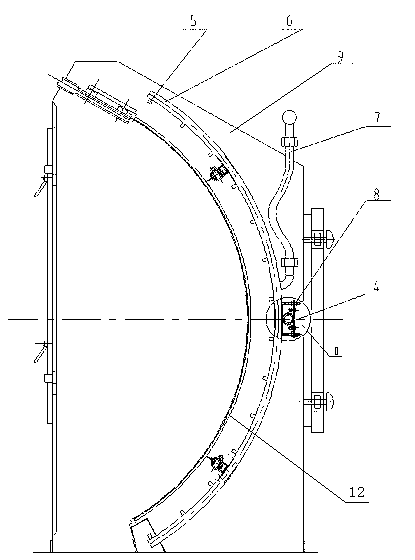

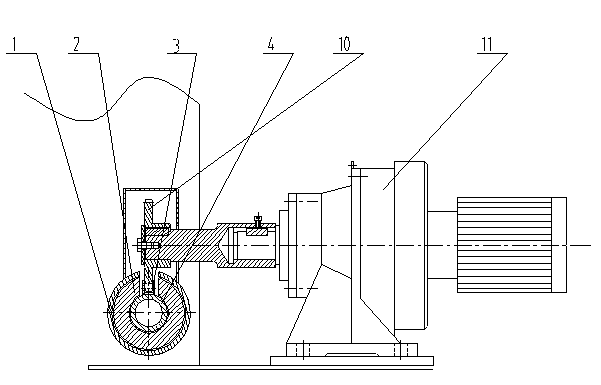

[0012] according to figure 1 As shown, the washing screen boxes 9 of the device of the present invention (there are 3 in this embodiment) are connected in series through the casing 1 in the middle, and the casing 1 is a shaft sleeve 2, and the optical axis 4 is set in the shaft sleeve 2 , the chain 3 is fixed on the optical axis 4 and forms a kinematic pair with the sprocket 10 on the main shaft of the motor 11 (refer to image 3 ), the motor 11 drives the sprocket 10 to drive the chain 3 to do axial reciprocating linear motion; as figure 2 , image 3 , Figure 4 As shown, each washing screen box body 9 is also provided with an arc nozzle 6 and is positioned at the rear of the washing screen 12. The arc nozzle 6 is fixed on the optical axis 4 by a fixing bolt 8, and the high pressure hose 7 is connected to the arc. Shape spray pipe 6 links to each other, several solid cone nozzles 5 are evenly installed on the arc spray pipe 6 and correspond to the surface of washing scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com