Solid construction waste processing and treating system

A construction waste and treatment system technology is applied in the field of systems for processing solid construction waste, achieving the effects of low cost, simple structure and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

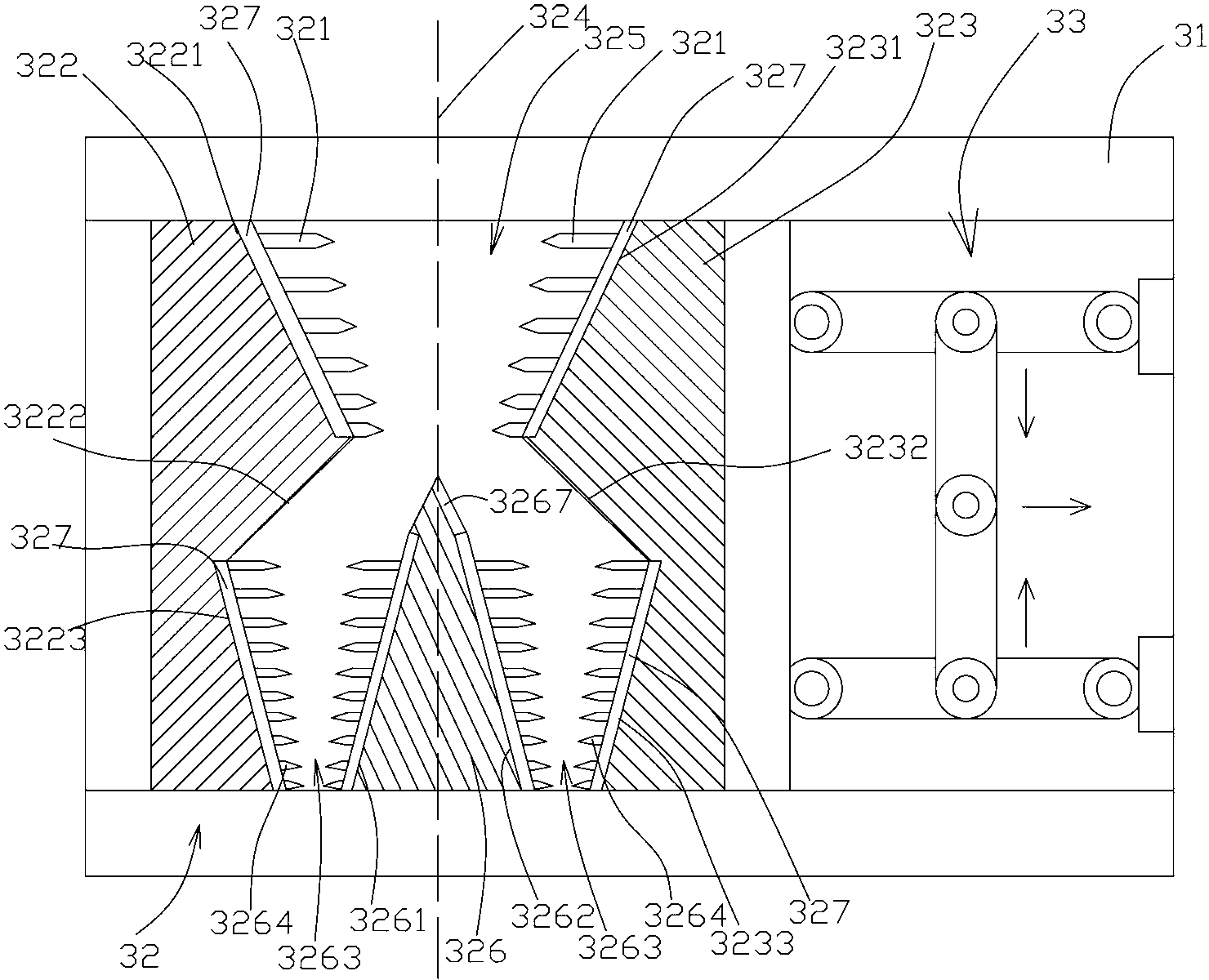

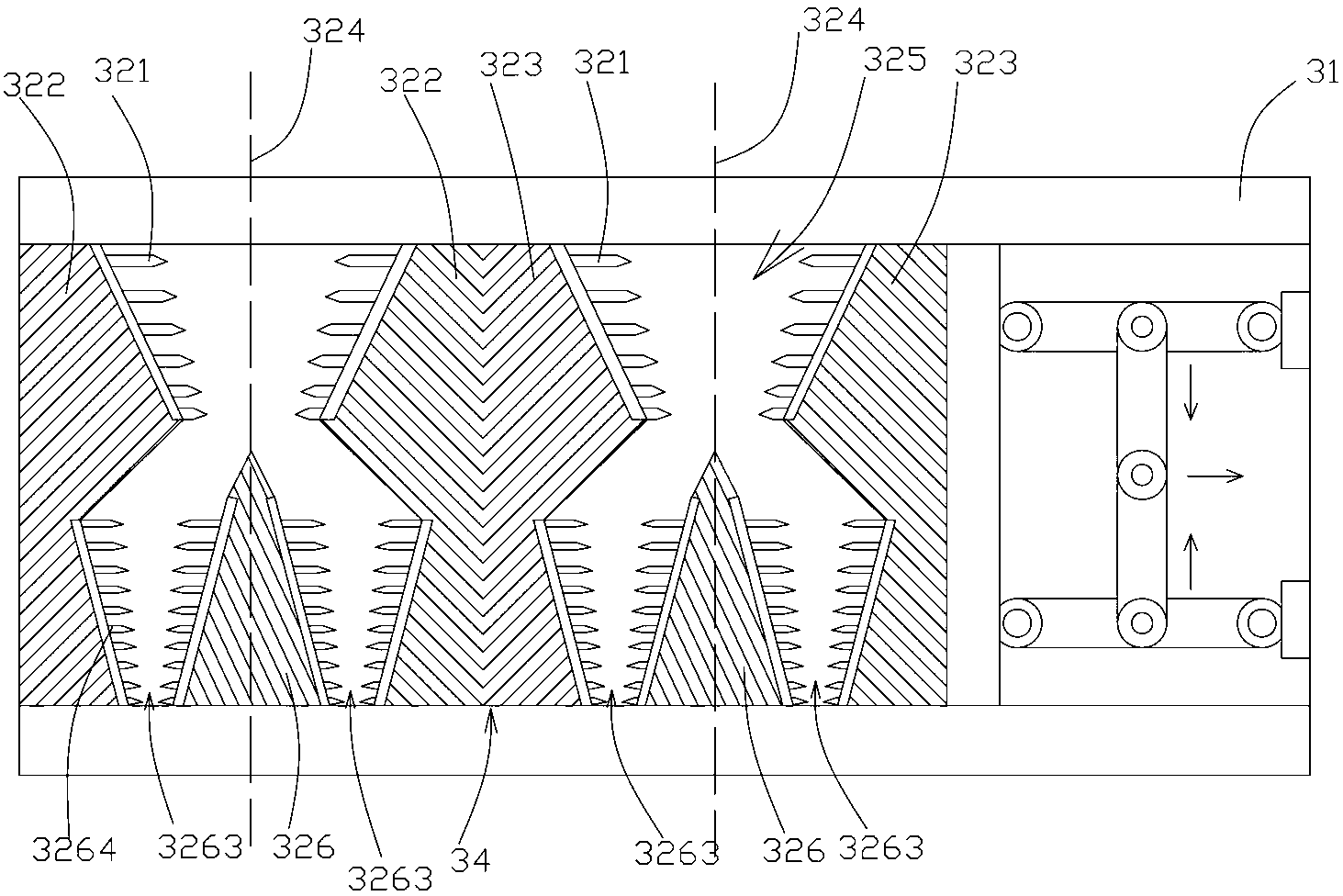

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

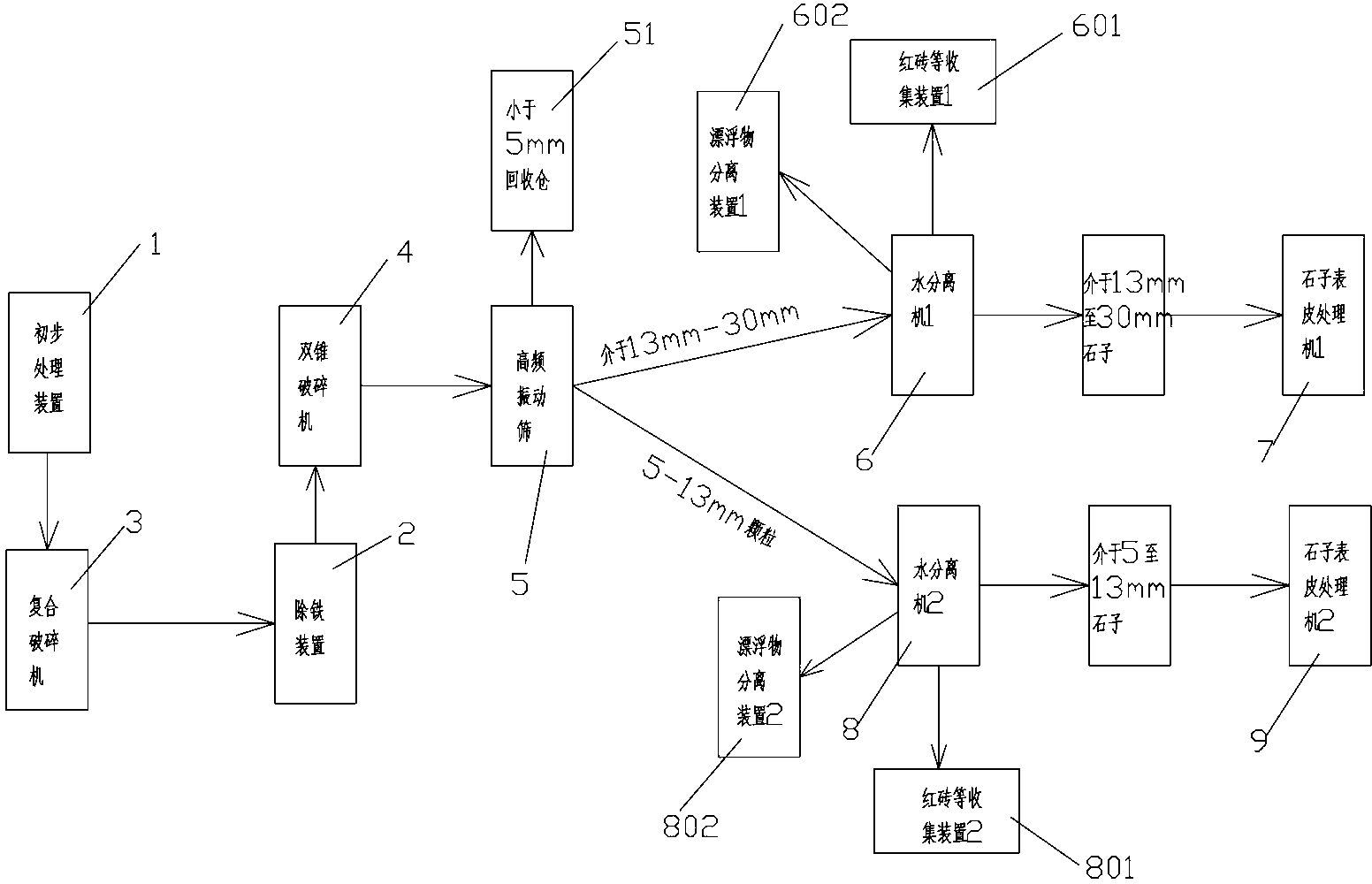

[0033] See figure 1 , figure 1 What is disclosed is a solid construction waste processing system, which consists of a compound crusher 3, an iron removal device 2, a double cone crusher 4, a high-frequency vibrating screen 5, a water separator 6, and a stone surface treatment machine 7 connected in sequence , the composite crusher 3 crushes the solid construction waste of the rated size to a predetermined particle size, and then removes the iron material through the iron removal device 2, and then enters the double cone crusher 4 for further crushing to particles below another predetermined particle size , and finally send the crushed particles to the high-frequency vibrating screen 5 to separate them into three grades of less than or equal to large, medium and small, and then send the particles of different grades to the water separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com