Manufacturing method of bamboo fiber

A manufacturing method and bamboo fiber technology, applied in the field of bamboo fiber manufacturing, can solve the problems of bamboo fiber products without flame retardant effect, cumbersome production steps, and long processing time, and achieve strong loss resistance, loss prevention, and penetration efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

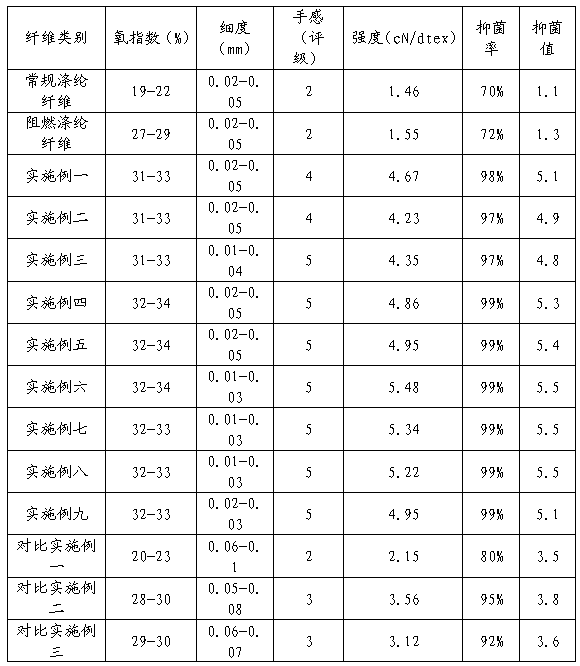

Examples

Embodiment 1

[0039] Choose annual moso bamboo. Use a perforator or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow cylinder or a semi-cylindrical tube, soak the flattened bamboo in the softening liquid, and the bamboo and the softening liquid The weight ratio is 100:8, and the softening solution is mixed with 100 parts by weight of water, 15 parts of milk mother soap, 8 parts of mineral oil and 5 parts of emulsifier OP;

[0040] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.02MPa, and then perform microwave softening treatment, the microwave frequency is 300MHz, and the microwave treatment time is 1min;

[0041] Rinse the softened bamboo with water, comb it, and then use a fiber separator to make the bamboo into a fiber bundle state; then cook it,

[0042] The cooking method is to place the fiber-opened bamboo filaments in the cooking ...

Embodiment 2

[0047] Choose biennial green bamboo.

[0048] Use a perforator or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow cylinder or a semi-cylindrical tube, soak the flattened bamboo in a softening solution, and the bamboo and the softened The weight ratio of the liquid is 100:2, and the softening liquid is mixed with 100 parts by weight of water, 20 parts of milk soap, 10 parts of mineral oil and 8 parts of Pingping plus O emulsifier;

[0049] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.001MPa, and then perform microwave softening treatment, the microwave frequency is 950MHz, and the microwave treatment time is 3min;

[0050] After the softened bamboo is rinsed with water, it is combed, and then the bamboo is made into a fiber bundle by a fiber separator; then steamed,

[0051] The cooking method is to place the fiber-opened ...

Embodiment 3

[0056] Choose three-year-old green bamboo. Use a puncher or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow conical or semi-conical shape, soak the flattened bamboo in the softening solution, and the bamboo and the softened The weight ratio of the liquid is 100:5, and the softening liquid is mixed with 100 parts by weight of water, 18 parts of milk soap, 9 parts of mineral oil and 6 parts of emulsifier OP;

[0057] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.01MPa, and then perform microwave softening treatment, the microwave frequency is 600MHz, and the microwave treatment time is 2min;

[0058] After the softened bamboo is rinsed with water, it is combed, and then the bamboo is made into a fiber bundle by a fiber separator; then steamed,

[0059] The cooking method is to place the fiber-opened bamboo filaments in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com