Fiber-reinforced resin sheet molding device

A fiber-reinforced resin and molding device technology, which is applied in the field of composite sheet production equipment, can solve the problems of reduced aesthetics, poor impact resistance, and easy cracking of the resin, and achieve no bubble residue, good wear resistance, and sticky Combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

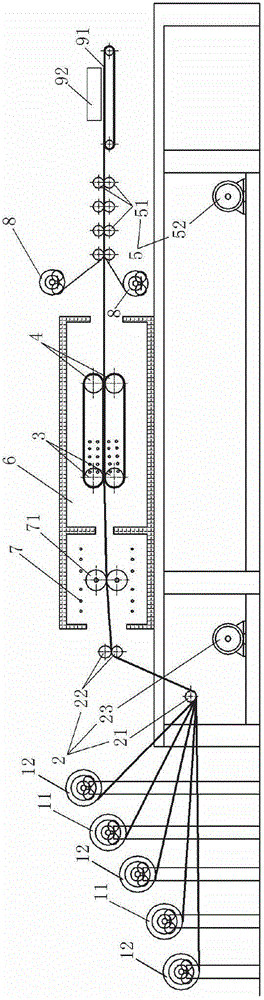

[0015] See figure 1 , the fiber-reinforced resin sheet forming device of this embodiment includes a thermoplastic resin film unwinding mechanism 11 and a fiber-reinforced fabric unwinding mechanism 12 arranged at intervals, for superimposing the thermoplastic resin film and the fiber-reinforced fabric at intervals for conveying The guide roller conveying mechanism 2, the hot pressing mechanism 3 and the cooling mechanism 4 for composite molding of thermoplastic resin film and fiber-reinforced fabric, and the traction transmission mechanism 5 for conveying composite molded sheet are arranged on the conveying path.

[0016] The hot pressing mechanism 3 and the cooling mechanism 4 are arranged in the heat preservation box 6 . The hot pressing mechanism 3 includes a set of pressure rollers arranged symmetrically up and down and with adjustable spacing. The pressure rollers of the pressure roller group are provided with heating components. The cooling mechanism 4 includes a set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com