Liquid forming device and liquid forming method for composite material stiffened plate

A technology of liquid molding and composite materials, which is applied in the field of composite material molding, can solve the problems of long manufacturing cycle and high cost, and achieve the effect of ensuring accuracy, ensuring relative position, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

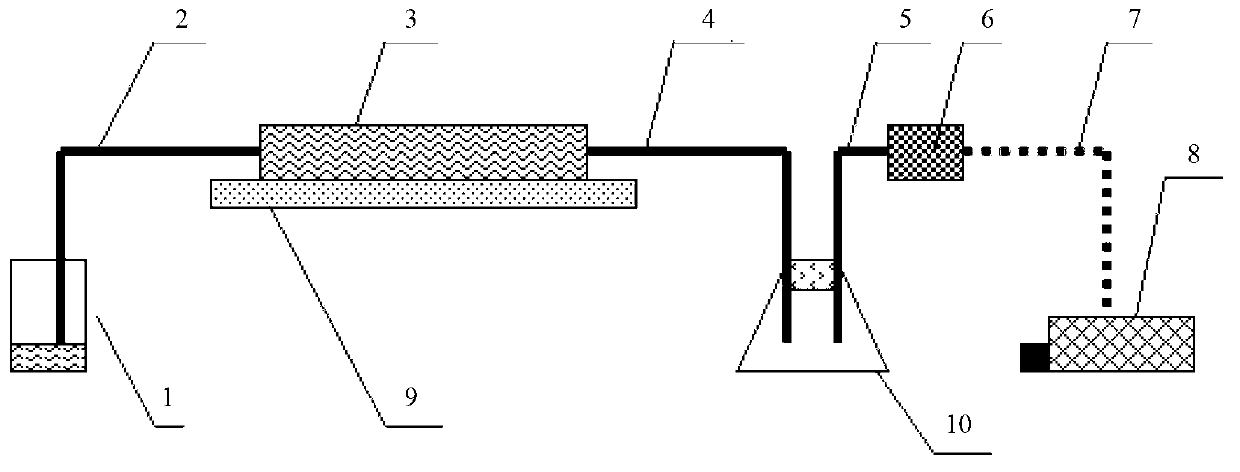

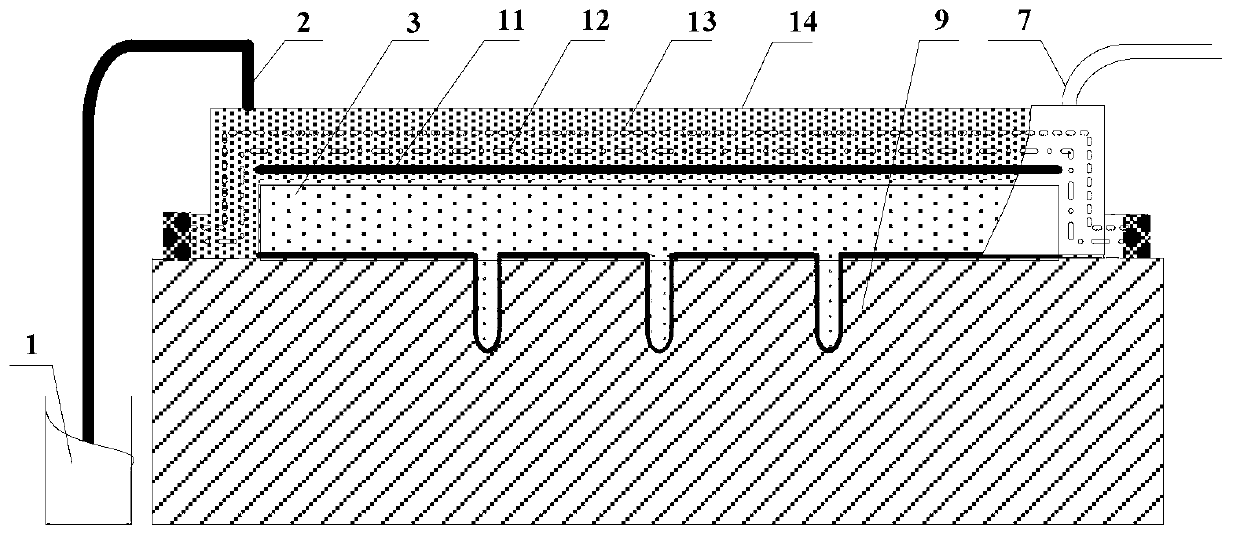

[0026] see figure 1 , which is a structural schematic diagram of a liquid forming device for a composite material stiffened plate of the present invention. The composite material stiffened plate liquid forming device includes a glue tank 1 , a packaging preform 3 , a forming mold 9 , a diversion bottle 10 , a connecting device 6 and a vacuum pump 8 . Among them, the packaging preform 3 is arranged on the molding mold 9 to form a molding assembly. One end of the molding assembly is connected to the glue tank 1 through the rubber inlet tube 2 to form an injection line, and the other end is connected to the diversion bottle 10 through the rubber outlet tube 4 to form a suction line. In this embodiment, the diversion bottle 10 is an Erlenmeyer flask, which is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com