SAPO-31 molecular sieve and preparation method thereof

A SAPO-31, molecular sieve technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of SAPO-31 high cost, complicated operation, long crystallization time, etc., to achieve a wide acid density And acid strength adjustable range, simple preparation process, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

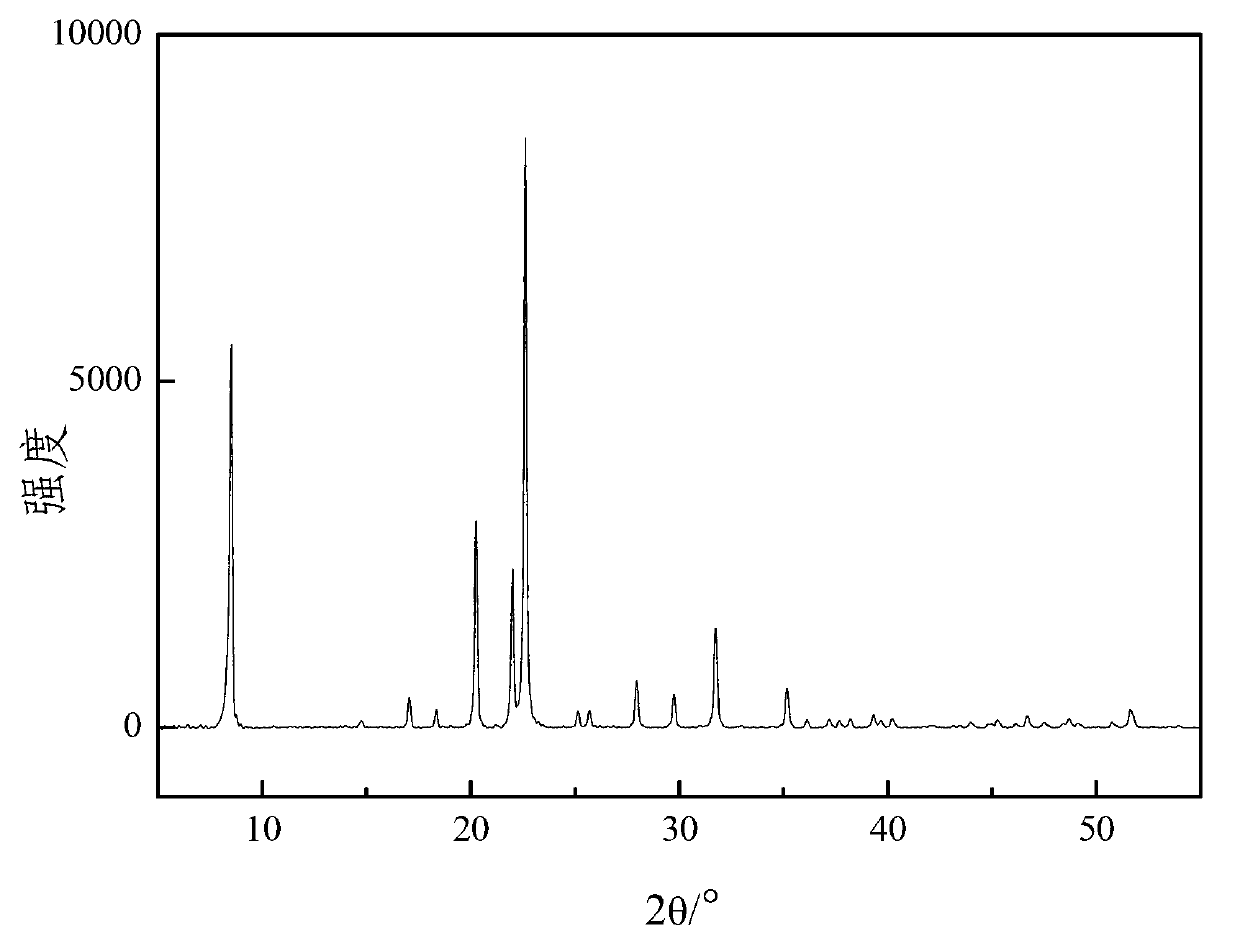

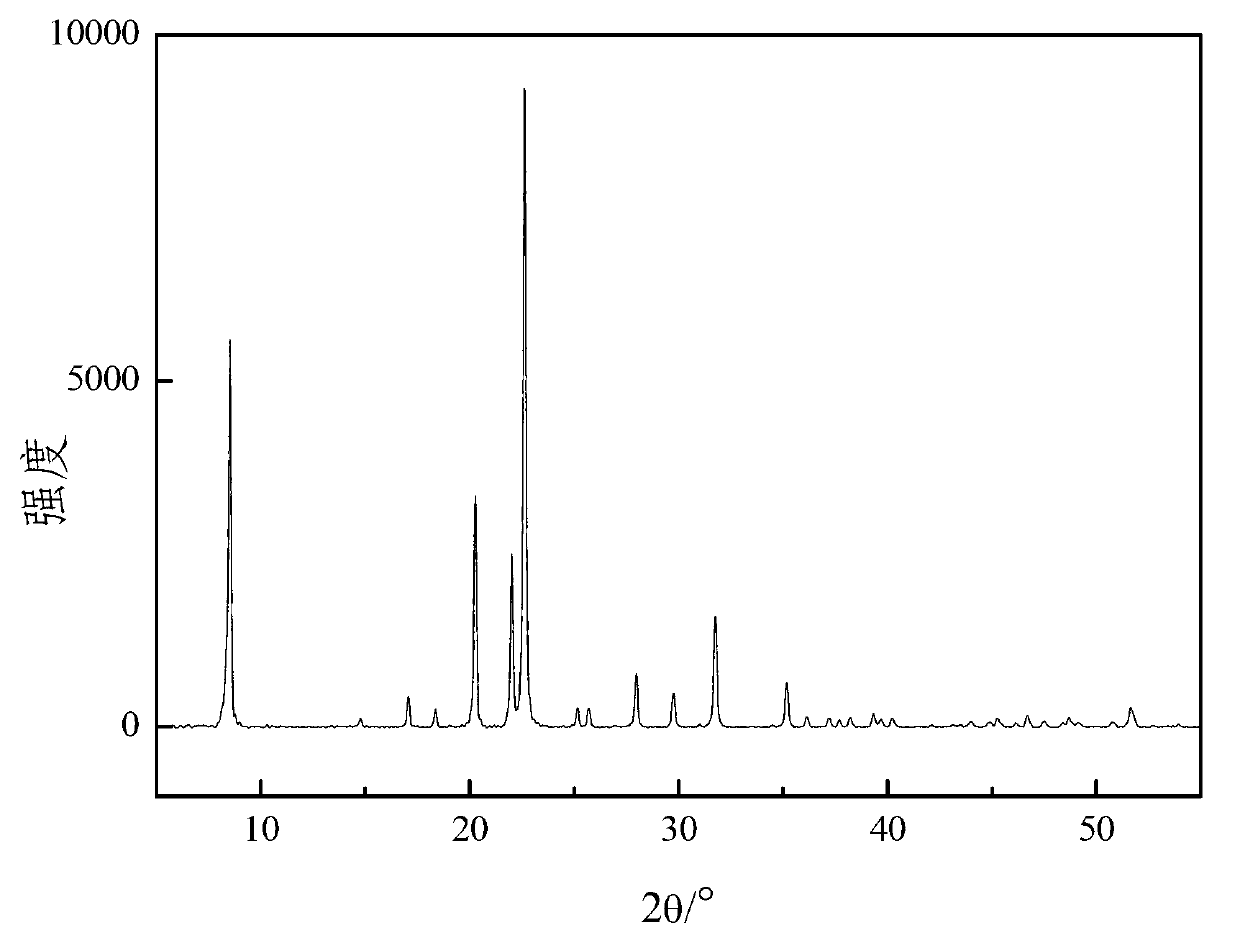

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: This embodiment provides a SAPO-31 molecular sieve, which is prepared from phosphoric acid, pseudo-boehmite, silica sol and di-n-butylamine; wherein, the mass ratio of pseudo-boehmite to phosphoric acid is ( 0.40~0.70):1, the mass ratio of silica sol to phosphoric acid is (0.30~0.90):1, and the mass ratio of di-n-butylamine to phosphoric acid is (0.50~0.90):1.

[0020] This embodiment has the following advantages: 1. The SAPO-31 molecular sieve provided by this embodiment adopts cheap pseudo-boehmite and silica sol as aluminum source and silicon source respectively, and adopts cheap di-n-butylamine as template agent, The prepared SAPO-31 molecular sieve is not only low in cost, but also due to the use of di-n-butylamine as a template, the synthesized SAPO-31 molecular sieve is not prone to SAPO-5, SAPO-11 and SiO 2 Miscellaneous crystals; 2. The SAPO-31 molecular sieve provided by this embodiment has a wider range of silicon-aluminum ratio, so t...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass percent concentration of phosphoric acid is 85%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is the method for preparing a kind of SAPO-31 molecular sieve described in specific embodiment one, specifically completes according to the following steps:

[0023] 1. Add pseudo-boehmite, silica sol, di-n-butylamine and water to phosphoric acid, and stir at a stirring rate of 800r / min~1000r / min for 5h~7h to obtain an initial gel; among them, pseudo-boehmite The mass ratio of silica sol to phosphoric acid is (0.40~0.70):1, the mass ratio of silica sol to phosphoric acid is (0.30~0.90):1, the mass ratio of di-n-butylamine to phosphoric acid is (0.50~0.90):1, water and The mass ratio of phosphoric acid is (2.0~4.0):1;

[0024] 2. Add the initial gel obtained in step 1 into a crystallization kettle, crystallize at a temperature of 170°C~190°C for 2h~48h, cool to 20°C~25°C, and obtain a solid-liquid mixture. The mixture is centrifuged, washed, and dried at a temperature of 100°C to 120°C for 10h to 24h to obtain a solid;

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com