Method for harmless treatment of incineration fly ash and composite structure made thereof

A technology of harmless treatment and treatment method, which is applied in the field of incineration fly ash treatment, can solve the problems of limited burial land, increase of treatment cost, waste of raw materials, etc., and achieve the effect of improving environmental protection, improving economic benefits, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

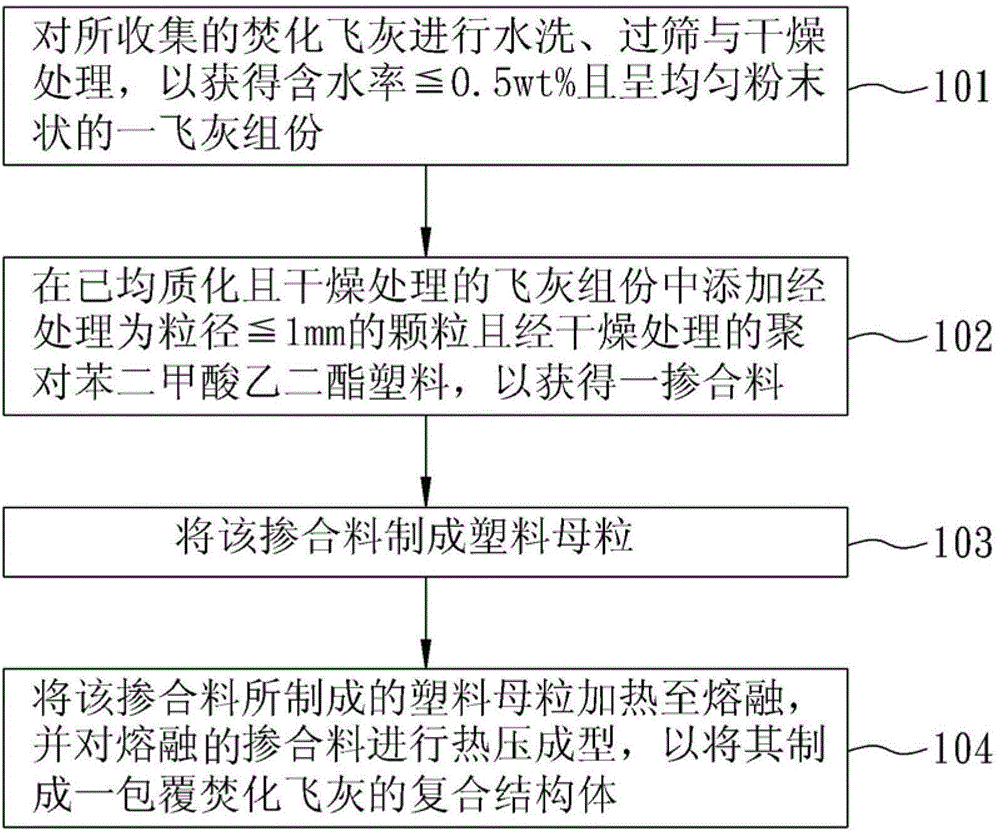

Method used

Image

Examples

specific example 1

[0042] Detection method:

[0043] The present invention is based on the Environmental Protection Agency's industrial waste toxicity characteristic dissolution procedure detection method (NIEA R201.14C) test to carry out the toxicant characteristic dissolution procedure (TCLP) test on the following test pieces and incineration fly ash powder. Among them, because the literature (please refer to the following "References" 1-11) shows that heavy metals with low boiling points such as Pb, Zn, Cu, Cd and Cr are the heavy metals in the incineration fly ash that are more likely to exceed the TCLP dissolution test standard, Therefore, the dissolution concentration of Pb, Zn, Cu, Cd and Cr is used as the detection target here, and based on this, it is judged whether the treatment method of the present invention helps to reduce the release of the aforementioned heavy metals, and can exert effective treatment effects.

[0044] "references":

[0045] 1. Zhuang Jiarong, Research on the Eff...

specific example 2

[0077] (1) Pretreatment of incineration fly ash: According to the method described in step (1-1) of , the fly ash component is obtained through pretreatments such as drying and sieving.

[0078] (2) PET pretreatment and blending with the fly ash component: the recovered PET waste is cut and crushed into particles with an average particle size of about 1 mm to obtain PET plastics, and the fly ash component is mixed with PET The plastics are mixed according to the following weight ratios: (b2) 1:99; (c2) 3:97; (d2) 4:96; (e2) 5:95; and (f2) 10:90 to obtain the admixture b3 respectively , c3, d3, e3, f3, and take the same amount of PET plastic without fly ash component as the control group a3, that is, the weight ratio of fly ash component to PET plastic in the control group a3 is 0:100.

[0079] (3) The plastics of the control group a3 and the admixtures of b3 to f3 are made into plastic master batches: the above-mentioned plastics and the admixtures in different proportions are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com