Spiral distributor

A distributing machine and screw technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problem that the distributing bucket does not give a specific guidance plan, and achieve good use effect, reduce specifications and dimensions, and reduce waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

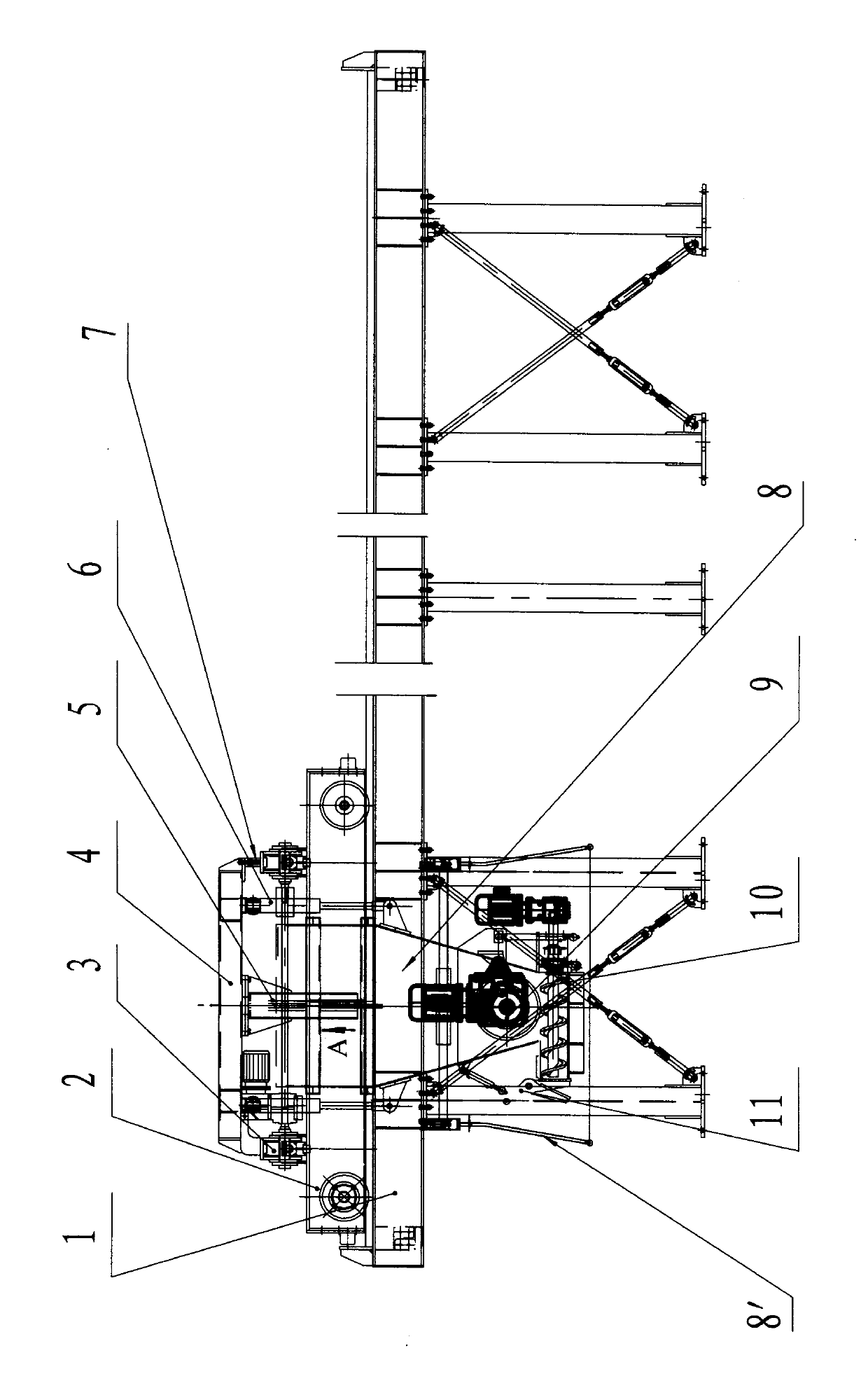

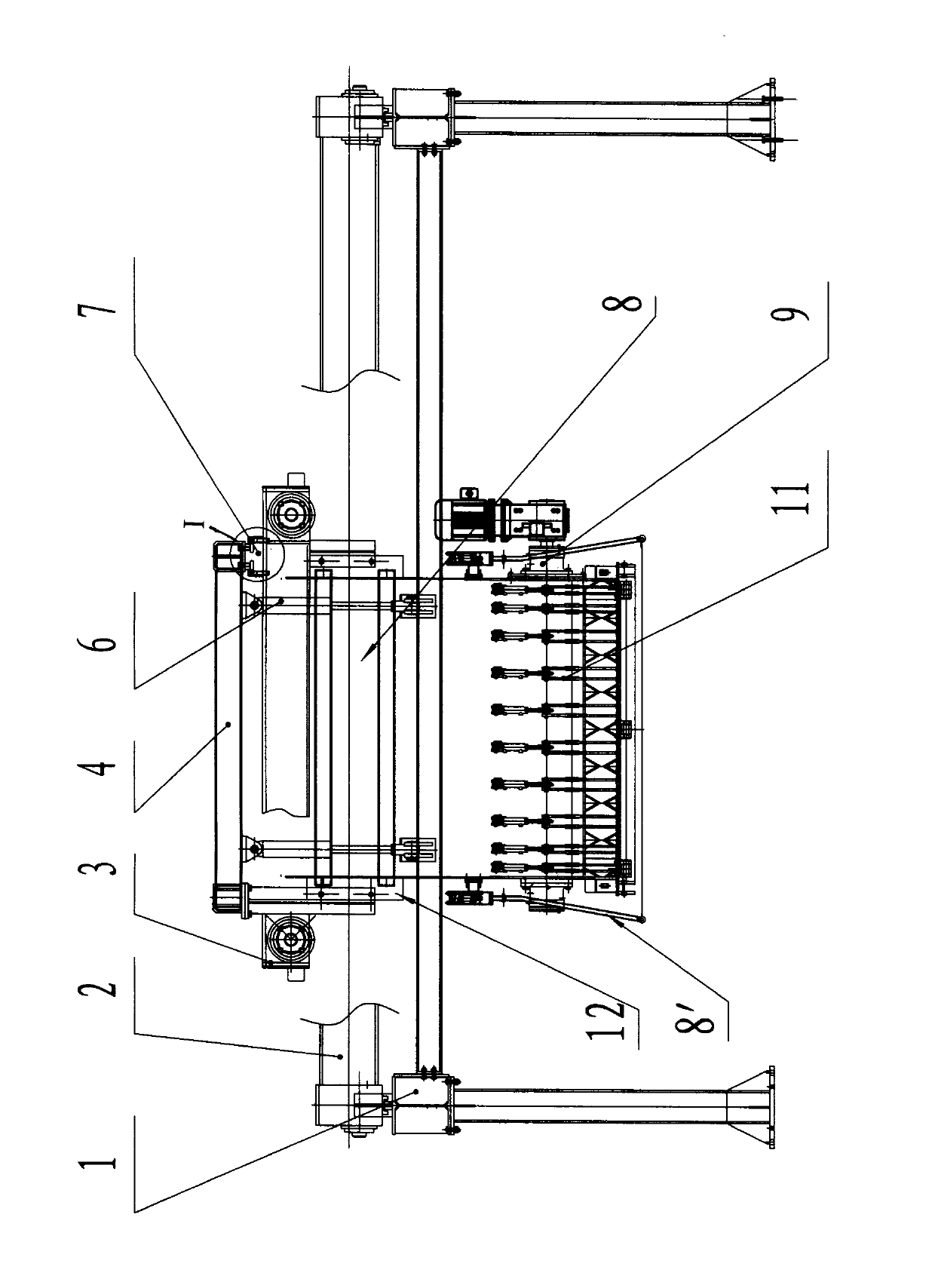

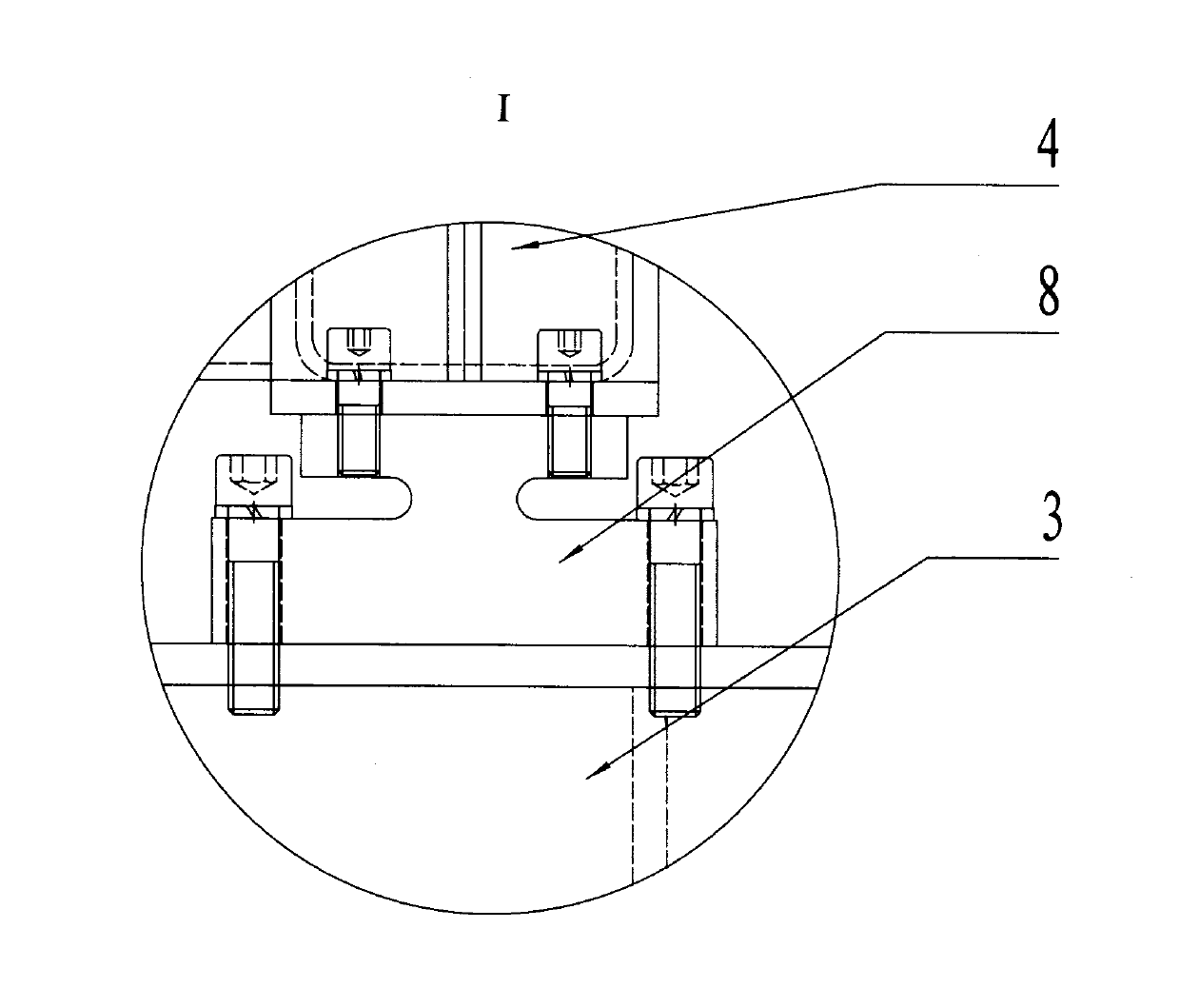

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8As shown, the present invention has a steel structure support 1, a distribution hopper 8, an upper frame 4 of the distribution hopper, a cart running device 2 with a distribution hopper for longitudinal movement installed on the steel structure support, a cart running device 2 installed on the cart running device The trolley running device 3 that moves laterally with the material distribution hopper, the stirring shaft assembly 9 installed on the material distribution hopper, the material distribution shaft assembly 10, and the door assembly 11, the present invention also has a main control electric cabinet not shown in the figure and Console, hydraulic device (hydraulic system). The steel structure support 1 may have crossed steel cables. There are a plurality of load cells 7 between the upper frame 4 of the distribution bucket and the trolley running device 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com