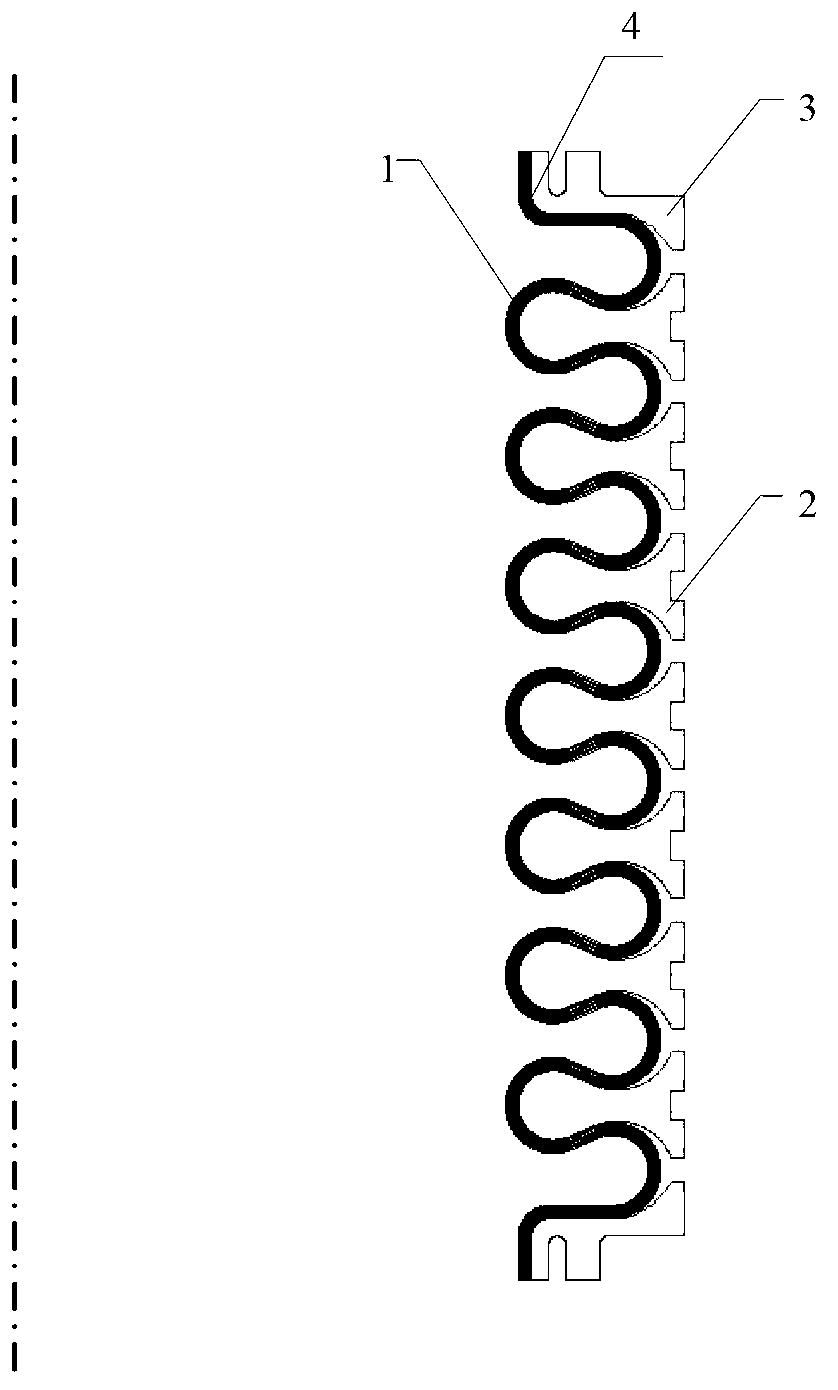

Enhancement type multi-layer S type metal bellows

A metal bellows, enhanced technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problem of inability to meet the requirements of large-diameter high-pressure pipelines for large displacement compensation, and achieve formability. , avoid disassembly problems, good fatigue life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

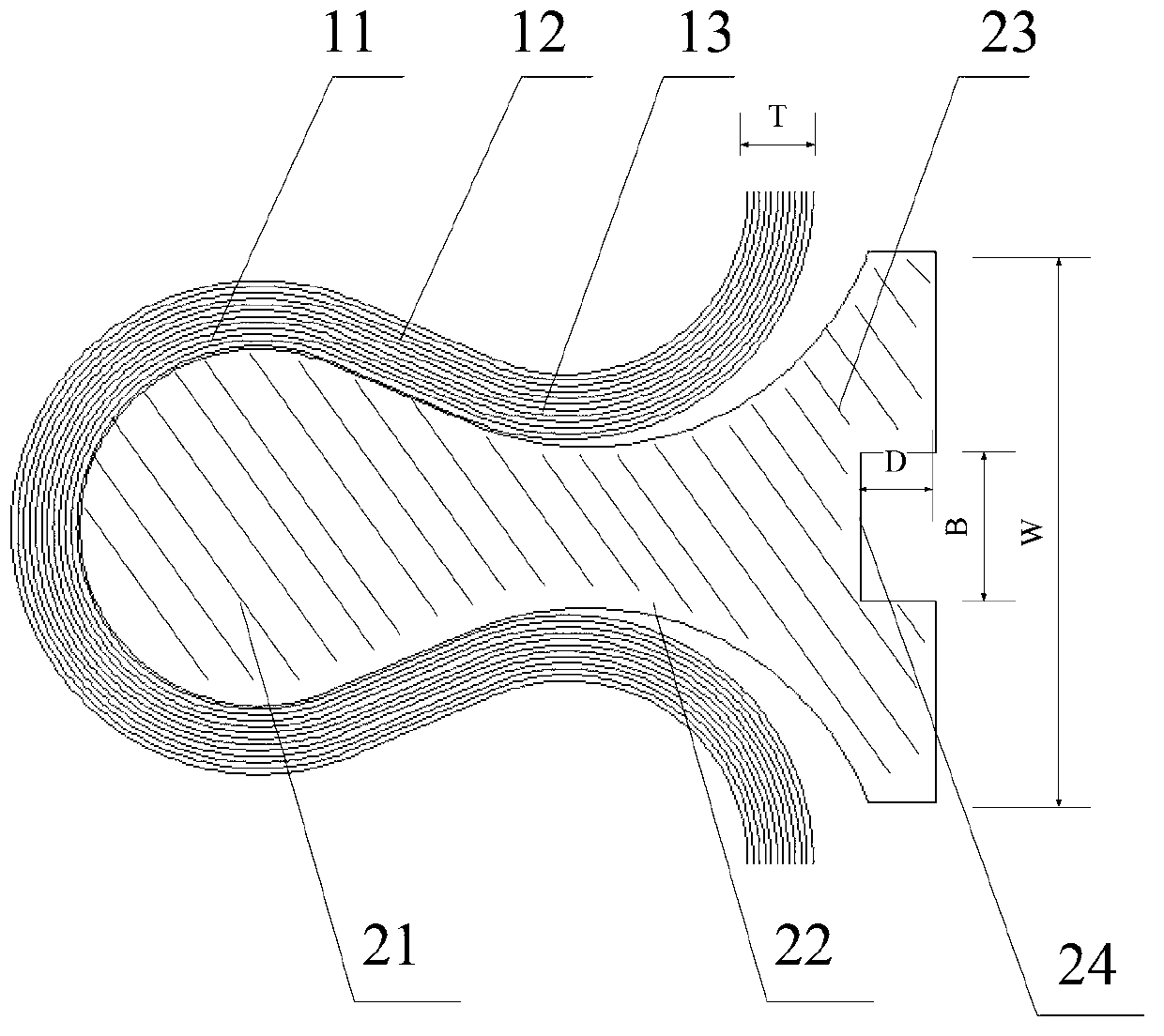

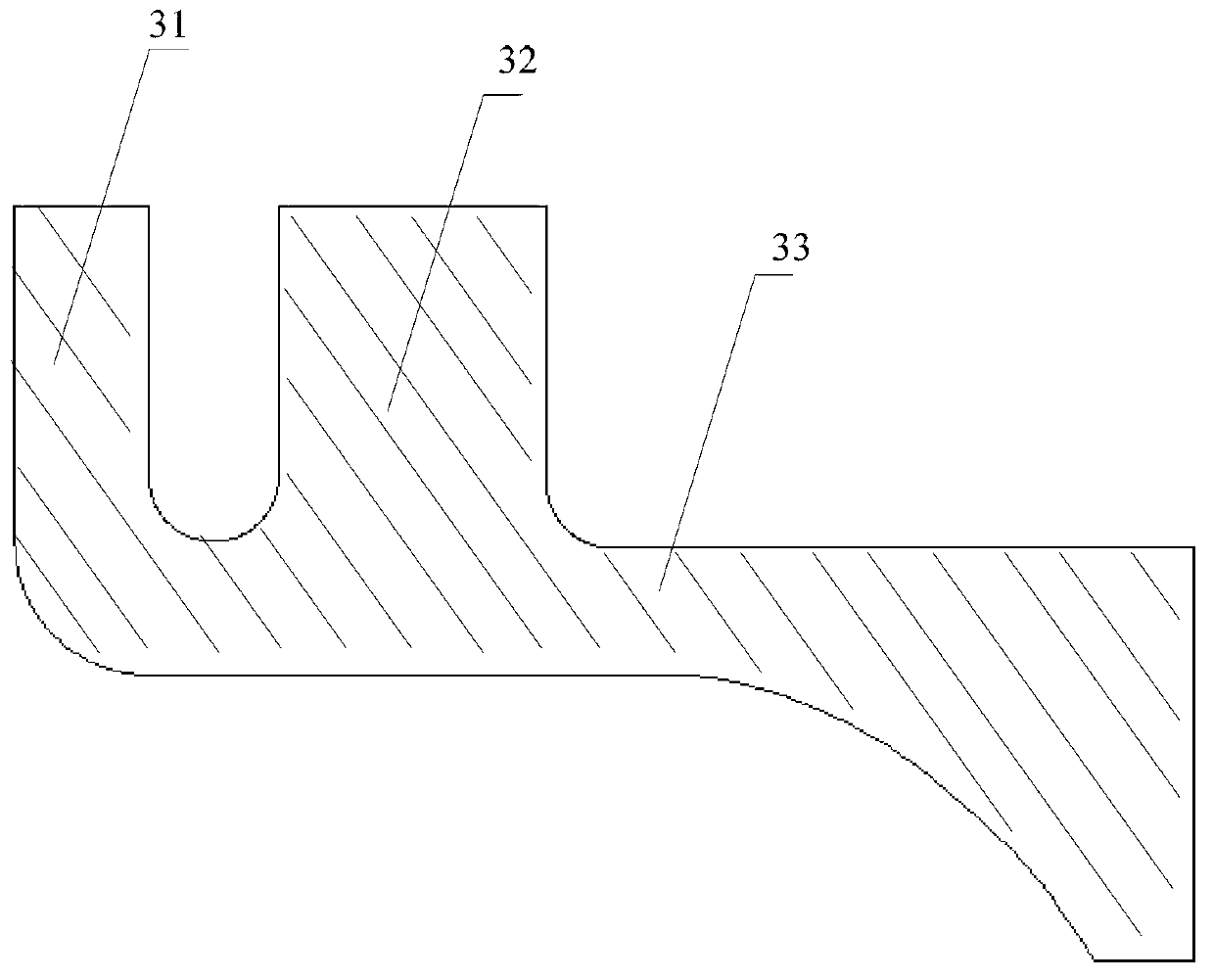

[0034] The enhanced S-shaped bellows with a diameter of 270mm and a total height of 380mm are made of 316L stainless steel, with 12 layers, a wave number of 8, a slenderness ratio of 1, a single layer thickness of 0.3mm, and a peak and valley radius of 11mm. The wave pitch ratio is 0.95, the maximum involute gap is 3.7mm, and the pressure resistance is 35MPa.

Embodiment 2

[0036] Enhanced S-shaped bellows with a diameter of 520mm and a total height of 800mm. The material is 1Cr18Ni9Ti stainless steel. The distance ratio is 1.25, the maximum involute gap is 8.3mm, and the pressure resistance is 38MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com