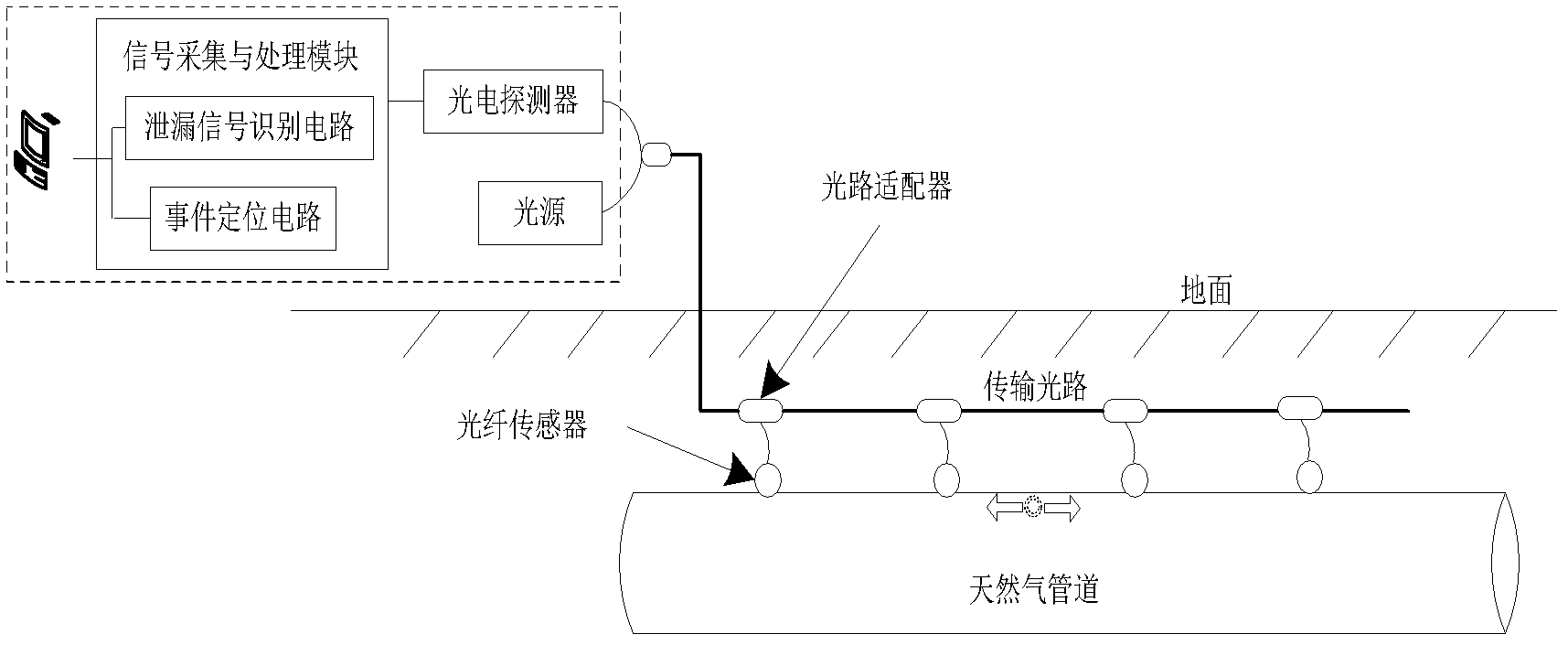

Optical fiber sensor for detecting natural gas pipeline leakage

A fiber optic sensor and natural gas pipeline technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as poor positioning effect, poor anti-interference ability, and inability to effectively solve the problem of gas pipeline leakage detection. Achieve adjustable detection sensitivity, high sensitivity, and good noise isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

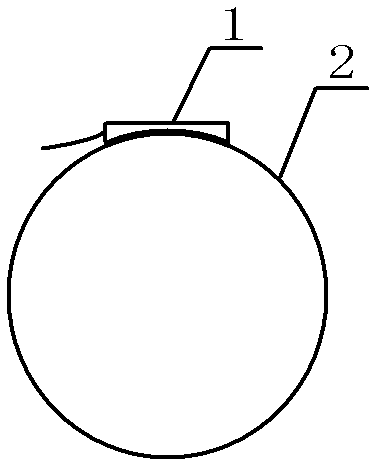

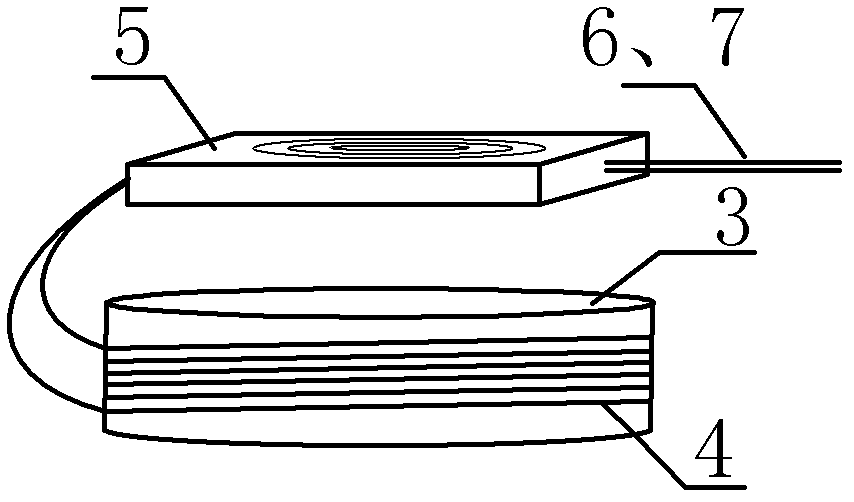

[0028] Embodiment. The composition of this example is as image 3 As shown, an optical fiber sensor 1 is installed every 1.5 km on the pipeline body, and an optical fiber sensor 1 senses a leakage signal at an axial point on the natural gas pipeline. By evenly distributing a plurality of optical fiber sensors 1 on the pipeline, the leakage of the entire pipeline can be detected. This optical fiber sensor is made up of elastic cylinder 3, optical fiber interferometer 4 and pigtail fiber box 5 (see image 3 ); wherein, the interference arm of the optical fiber interferometer is uniformly and orderly wound on the periphery of the elastic cylinder, and the optical fiber and the cylinder are tightly bonded together with an adhesive, and the remaining optical fiber interferometer and its related devices after winding will be Neatly coiled in the pigtail fiber box 5, the input and output optical fibers 6, 7 are exposed; the pigtail box 5 is fixed on the top of the elastic cylinder 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com