Ball pin assembly high and low temperature mud water spray durability test bench

An endurance test and ball stud technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of only one ball stud assembly durability test, poor accuracy and precision, There are too many clamping parts to achieve the effect of good application value, stable work and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

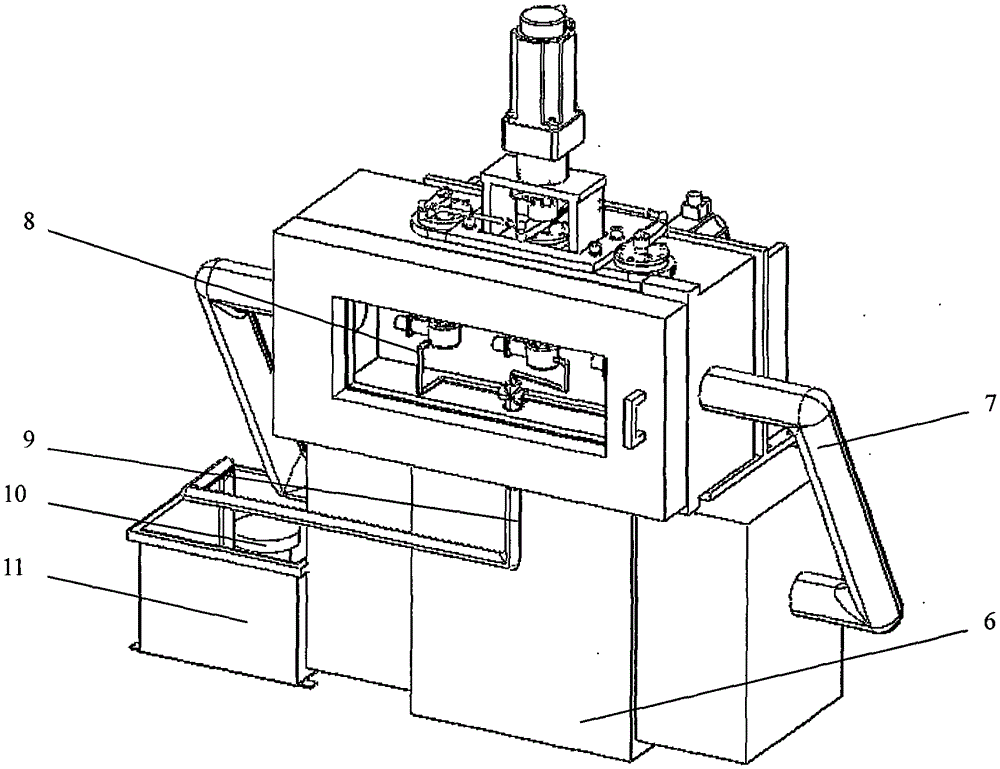

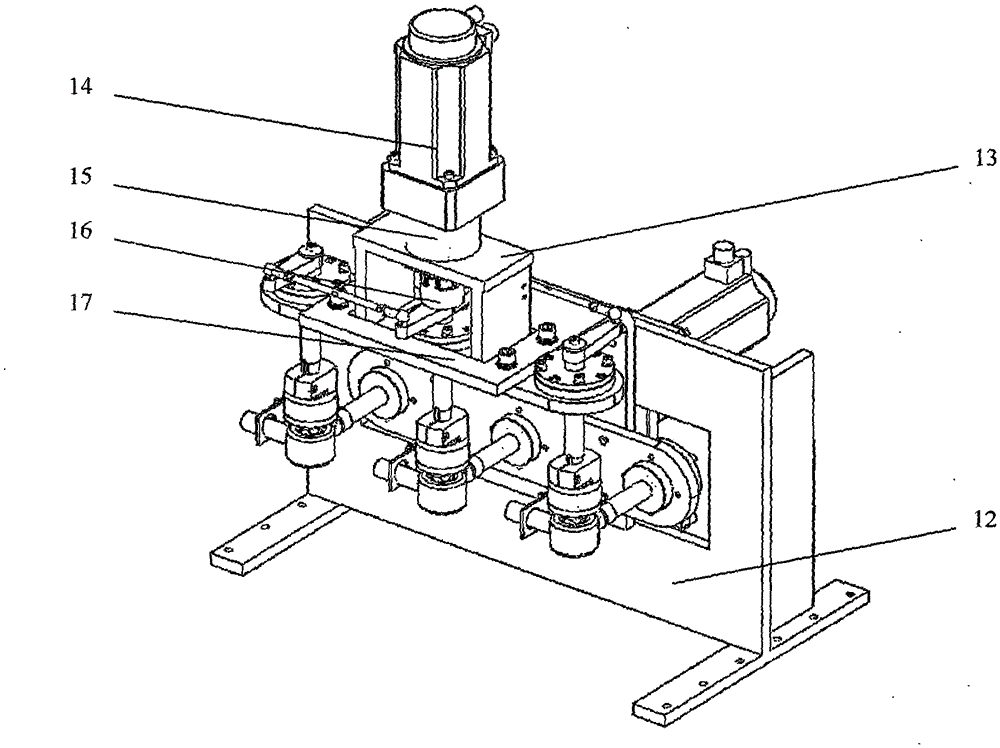

[0019] The test bench of the present invention is mainly composed of a bench, a high and low temperature mechanism, a mud water spray mechanism, a ball stud rotation mechanism, a ball stud swing mechanism, and a PLC control system.

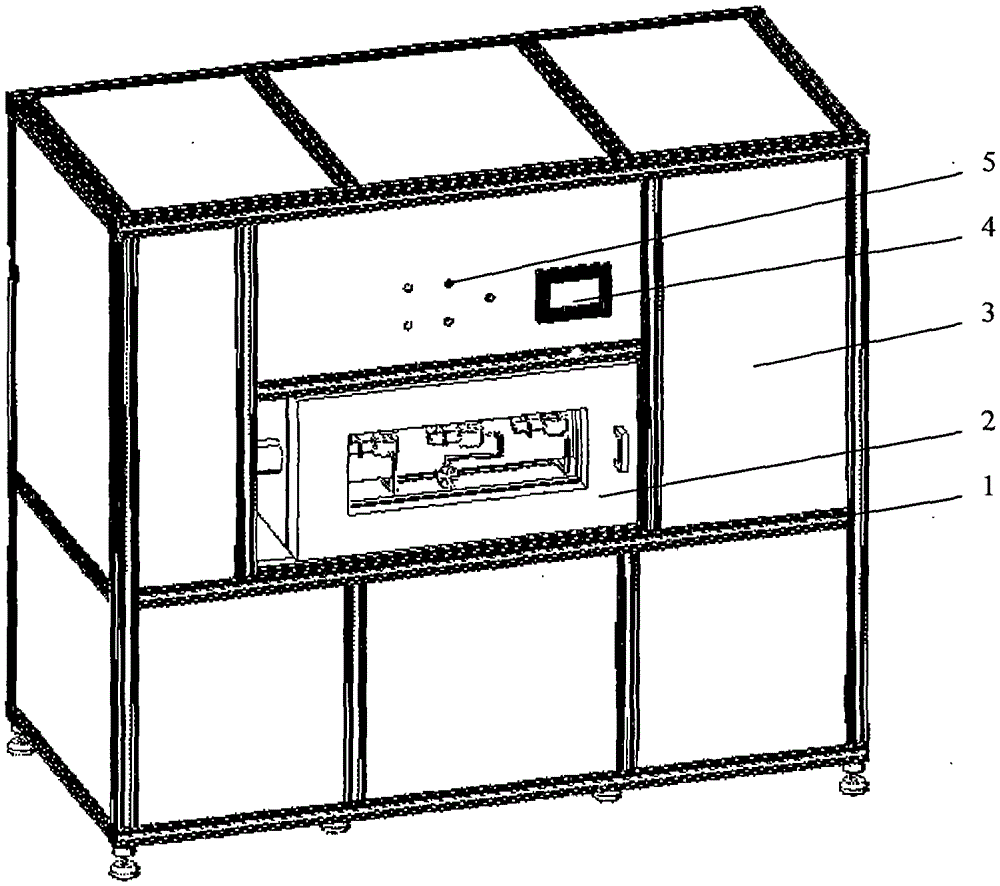

[0020] see figure 1 , The bench adopts industrial aluminum profile frame 1, and the mechanism and components of the test bench are all installed and fixed on the bench. For the beauty and dustproof of the test bench, a stainless steel plate 3 is installed on the surface of the test bench.

[0021] see figure 1 , 2 , the high and low temperature mechanism is mainly composed of a high and low temperature box 2, a high and low temperature generating box 6, and an air conditioning channel pipeline 7, and the high and low temperature box 2 and the high and low temperature generating box 6 are all fixed on the stand. According to the temperature signal of the PLC control system, the temperature of the air in the high and low temperature generating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com