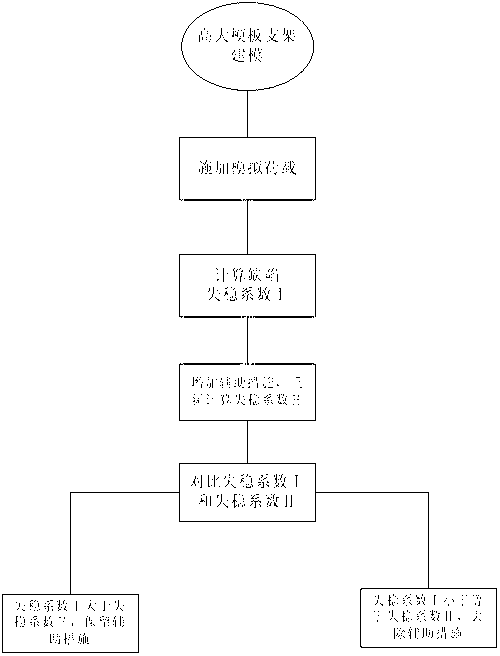

Method for preventing progressive collapse of high and large formwork support

A tall formwork, continuous technology, applied in the connection of formwork/formwork/work frame, special data processing applications, on-site preparation of building components, etc., can solve the different load effects, without thinking about the use of large formwork supports Due to the role, the concrete is not mature and other problems, to prevent the collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] Taking the formwork support of one of the long-span concrete beams as an example, the analysis and calculation are carried out. According to the construction status, the load range of the supporting formwork bracket under the beam is 500mm wide of the beam plus a certain range of 400mm wide on both sides of the beam, and the load on this surface in the construction status is 22.02kN / m 2 .

[0025] The basic data of the formwork support include:

[0026] 1. The horizontal distance of the pole is 0.5m, and the vertical distance is 1m. Since the support height is 8m, the vertical connection of the pole is connected by butt fasteners;

[0027] 2. The step distance between the horizontal bar and the vertical bar is 1.5m;

[0028] 3. Set vertical and horizontal sweeping poles, 0.2m from the ground;

[0029] 4. Set up connecting wall parts, and gradually distribute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com