Aluminum alloy with excellent high-temperature strength and thermal conductivity, and process for production thereof

A technology of high temperature strength and manufacturing method, applied in the field of aluminum alloy, can solve the problems of lowering, crystallization easily destroys room temperature strength, etc., and achieves the effect of improving high temperature strength, excellent high temperature strength, and light weight ratio strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4、7、8

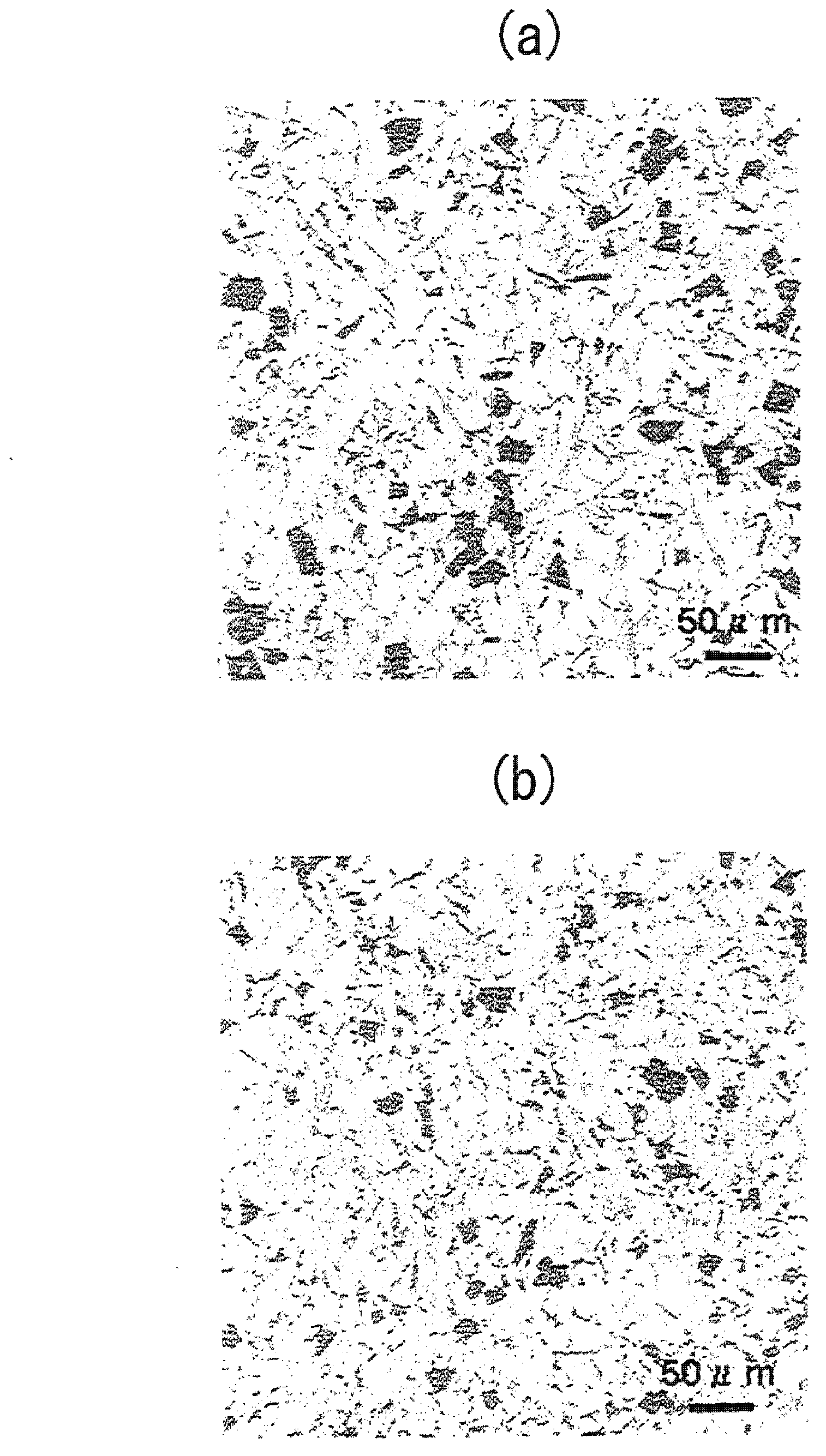

[0068] Aluminum alloy molten liquids adjusted to the compositions shown in Table 1 were prepared. The aluminum alloy molten liquid is cast by gravity casting into the JIS4 ship model (Japanese: 船形) whose soup injection temperature is heated from 740°C to 200°C. In addition, the cooling rate at this time was 24° C. / s to the liquidus line, and 5.9° C. / s from the liquidus line to the solidus line.

[0069] The obtained mold casting material was subjected to an aging treatment at 220° C. for 4 hours, followed by air cooling.

[0070] In order to perform a 350°C tensile test and a room temperature tensile test, a high temperature tensile test piece and a room temperature tensile test piece were cut out from each heat-treated alloy by cutting. In the high-temperature tensile test, a test piece preheated at 350° C. for 100 hours was used as an object.

[0071] The evaluation of the thermal conductivity was performed by measuring the thermal conductivity proportional to each heat-tr...

Embodiment 5

[0076] The aluminum alloy molten liquid adjusted to the composition shown in Table 1 was melted. The aluminum alloy molten liquid was cast from a casting temperature of 700°C into a JIS4 ship model heated to 160°C by gravity casting. In addition, other castings were performed in the same manner as in Examples 1 to 4.

[0077] The obtained mold casting material was subjected to an aging treatment at 220° C. for 4 hours, followed by air cooling. Thereafter, in the same manner as in Example 1, a 350° C. tensile test, a room temperature tensile test, and evaluation of thermal conductivity were performed.

[0078] Table 2 shows the 350° C. tensile properties, room temperature tensile properties, and thermal conductivity at this time together.

Embodiment 6

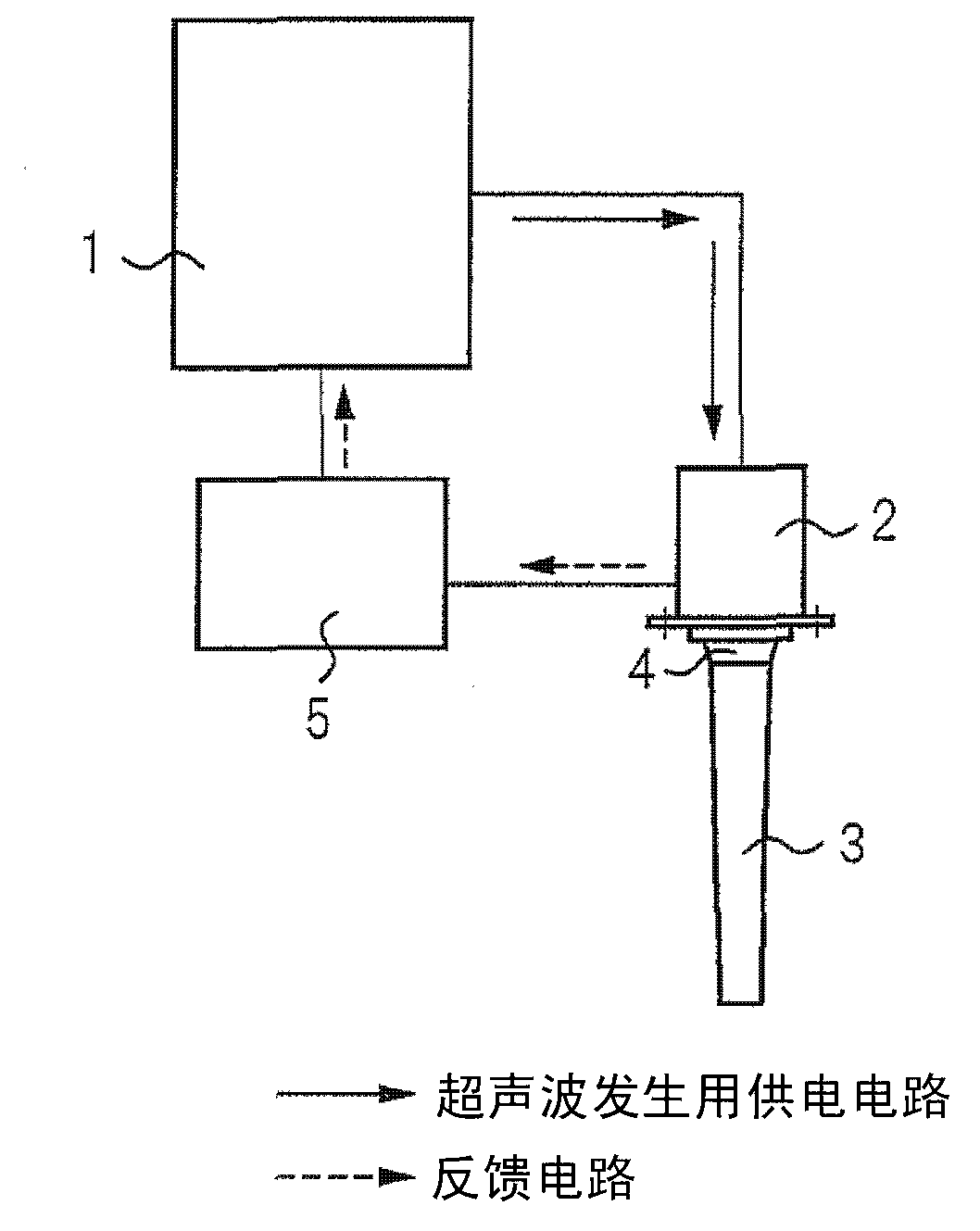

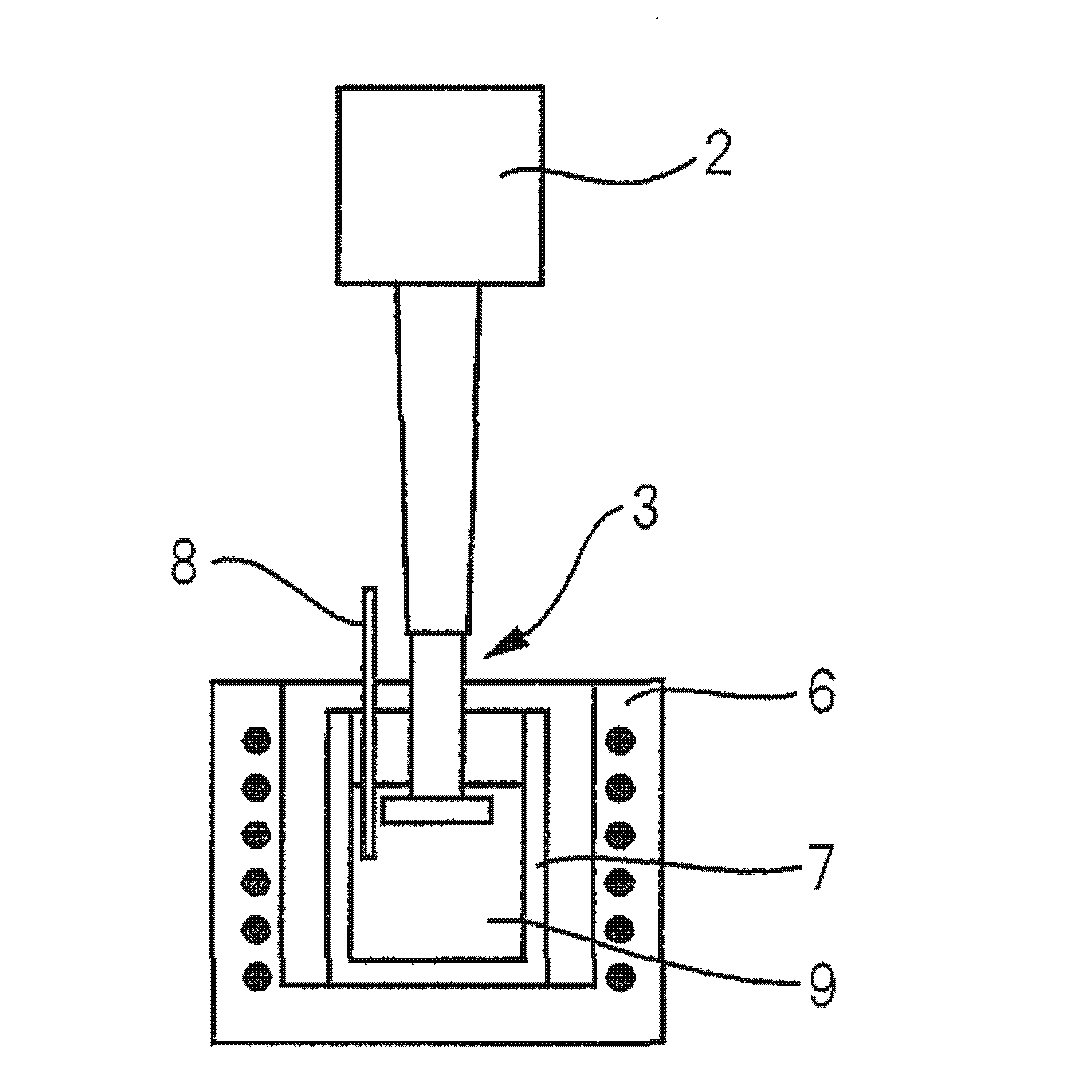

[0080] As shown in Table 1, an aluminum molten liquid having the same composition as in Example 5 was prepared in a crucible disposed in a melting furnace. Then, after preheating the ultrasonic steel mold made of Nb-Mo alloy in the preheating furnace, the steel mold is immersed in the aluminum molten liquid in the crucible and irradiated with ultrasonic waves.

[0081] The ultrasonic generator used at this time was the ultrasonic generator manufactured by VIATECH Corporation, and it was set to irradiate ultrasonic waves with a frequency of 20 to 22 kHz and an acoustic output of 2.4 kw. The vibration amplitude of the steel mold was set to 20 μm (p-p). The crucible was taken out, and after 20 seconds from the end of ultrasonic irradiation, gravity casting was performed in a JIS No. 4 metal mold heated to 160° C. at a casting temperature of 700° C. The liquidus line of the molten liquid at this time was 700° C. with respect to the end temperature of ultrasonic waves of 640° C., ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com