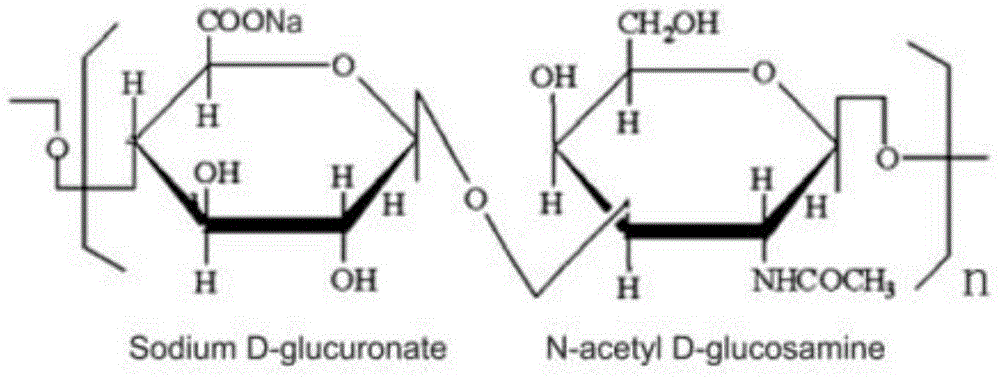

Preparation method of high-viscoelasticity sodium hyaluronate gel

A technology of sodium hyaluronate and elasticity, applied in skin diseases, bone diseases, aerosol delivery, etc., can solve the problems of increased production cost, reduced income, high price, etc., to improve production efficiency, improve viscoelasticity, high viscosity The effect of the bullet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the sodium hyaluronate raw material (molecular weight: 920,000), accurately weigh three parts of 2.5g, 5.0g and 7.5g, dissolve it in the PBS buffer solution prepared by the small-volume injection workshop, and prepare 0.5%, 1.0% and 1.5% % concentration of sodium hyaluronate solution, respectively numbered A-1, B-1, C-1, test and record the pH value, after the preparation is completed, take half (250ml) of the volume of the above numbered sodium hyaluronate solution, start stirring, speed 200 revolutions / min, slowly add dilute hydrochloric acid with a concentration of 1+6 into the liquid medicine at a rate of 5-20ml / min, and adjust the pH value. When the pH value drops below 3.2, observe the phenomenon at the same time, and the apparent viscosity is sharp Stop adding dilute hydrochloric acid immediately after the increase, record the final pH value, and the reaction is terminated to obtain highly viscoelastic sodium hyaluronate gels, numbered A-2B-2 and C-2 respecti...

Embodiment 2

[0029] Take the sodium hyaluronate raw material (molecular weight: 820,000), accurately weigh three parts of 2.5g, 5.0g and 7.5g, dissolve it in the PBS buffer solution prepared by the small-volume injection workshop, and prepare 0.5%, 1.0% and 1.5% % concentration of sodium hyaluronate solution, respectively numbered D-1, E-1, F-1, test and record the pH value, after the preparation is completed, take half (250ml) of the volume of the above numbered sodium hyaluronate solution, start stirring, and the speed 300 revolutions / min, slowly add dilute hydrochloric acid with a concentration of 1+4 to the liquid medicine at a rate of 5-20ml / min to adjust the pH value, when the pH value drops below 3.0, observe the phenomenon at the same time, the apparent viscosity is sharp Immediately stop adding dilute hydrochloric acid after the increase, record the final pH value, and the reaction is terminated to obtain highly viscoelastic sodium hyaluronate gels, respectively numbered D-2E-2 and...

Embodiment 3

[0031] Take the sodium hyaluronate raw material (molecular weight: 900,000), accurately weigh three parts of 2.5g, 5.0g and 7.5g, dissolve it in the PBS buffer solution prepared by the small-volume injection workshop, and prepare 0.5%, 1.0% and 1.5% % concentration of sodium hyaluronate solution, respectively numbered G-1, H-1, I-1, test and record the pH value, after the preparation is completed, take half (250ml) of the volume of the above numbered sodium hyaluronate solution, start stirring, speed 500 revolutions / min, slowly add dilute hydrochloric acid with a concentration of 1+5 to the liquid medicine at a rate of 5-20ml / min, and adjust the pH value. When the pH value drops below 3.5, observe the phenomenon at the same time, and the apparent viscosity is sharp Immediately stop adding dilute hydrochloric acid after the increase, record the final pH value, and the reaction is terminated to obtain highly viscoelastic sodium hyaluronate gels, respectively numbered G-2H-2 and I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com