Method of treating sulfur-containing tail gas

A treatment method and a technology for tail gas, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of difficult recovery and treatment of by-products, low efficiency of desulfurization technology, and low economic value, and achieve good economic benefits. and social benefits, avoid dealing with problems, and absorb good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

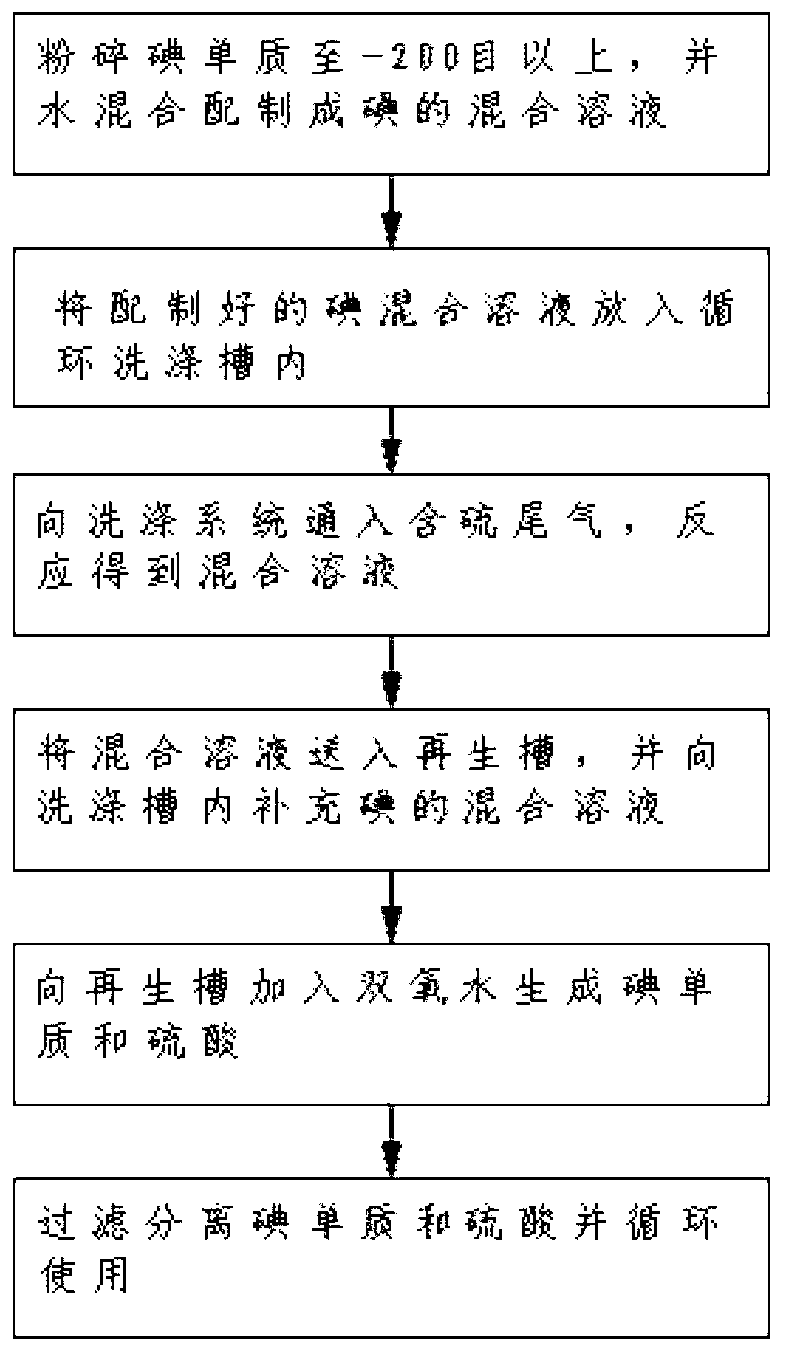

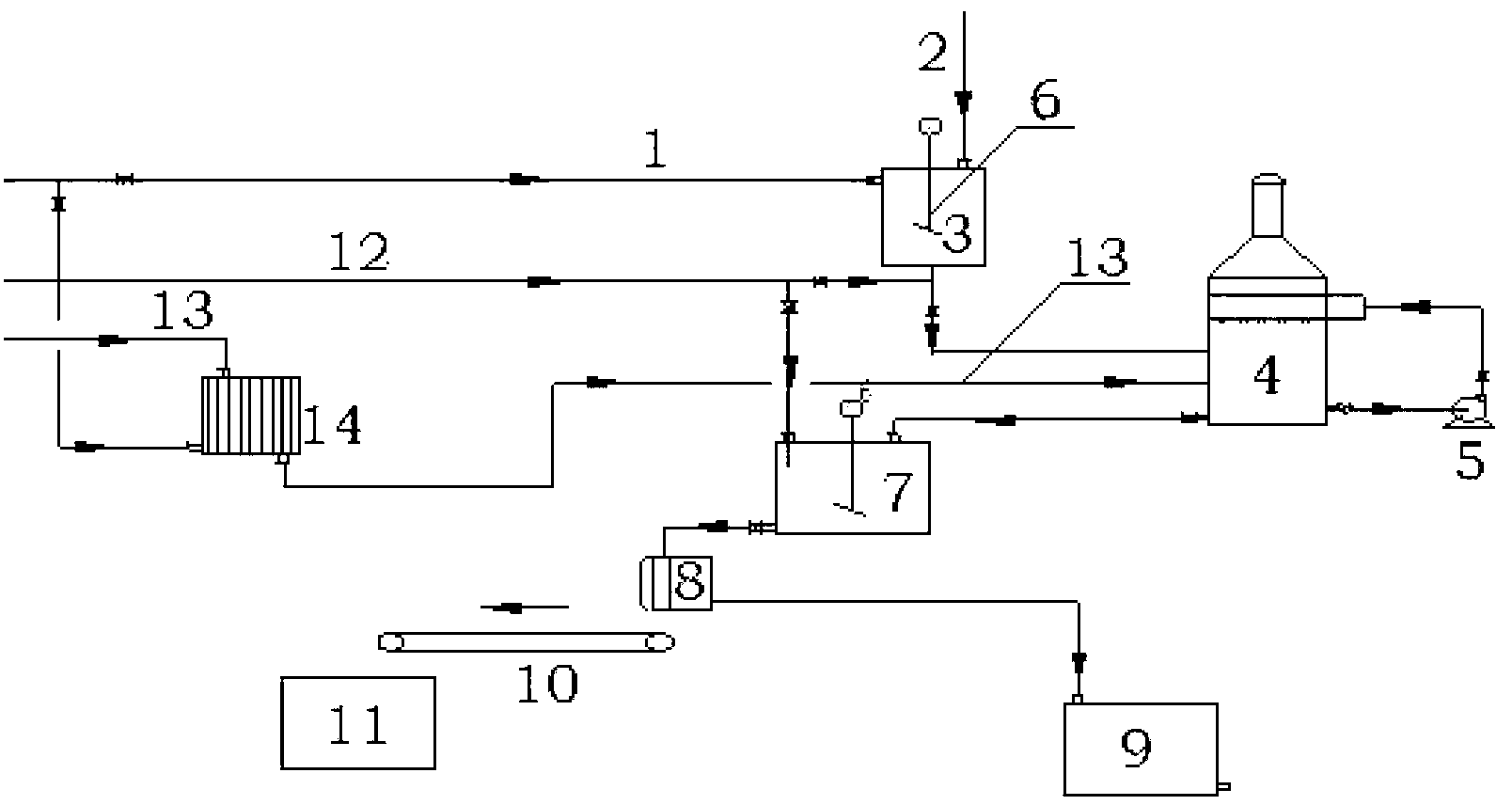

Method used

Image

Examples

Embodiment 1

[0036] Mix 1Kg of iodine element with a particle size of 200 mesh and 20Kg of water to prepare a washing liquid, place it in a circulating washing tank, and pass through the lower end of the circulating washing tank with a temperature of 40 ° C and SO 2 The gas with a content of 1500mg / L is washed countercurrently under the action of the circulating washing pump. After washing, the gas is detected by SO 2 The content is 8mg / L.

Embodiment 2

[0038] Fully stir and mix 20Kg of iodine elemental substance with a particle size of 250 mesh and 280Kg of water to prepare a washing liquid, put the washing liquid into the circulating washing tank, and pass SO into the circulating washing tank 2 The gas with a content of 2400mg / L is circulated and washed in the tank under the action of the circulating washing pump, and the exhaust gas after washing is detected by SO 2 The content is 8mg / L.

Embodiment 3

[0040] 25Kg of iodine element with a particle size of 200 mesh and 270Kg of water are fully stirred and mixed evenly to prepare a washing liquid, which is mixed with SO in a circulating washing tank 2The gas with a content of 2400mg / L is countercurrently washed, and at the same time, hydrogen peroxide is passed into the circulating washing tank at a rate of 1.5Kg per hour, and the exhaust gas after washing is analyzed for SO 2 The content is 5mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com