Method and device for preparing gas hydrate by direct phase conversion heat

A technology of phase conversion heat and hydration, applied in the direction of mixing methods, chemical methods for reacting liquid and gas media, heat exchange materials, etc., can solve problems such as uneven temperature and affecting heat exchange effects, and achieve continuous Operation, easy constant temperature operation, effect of suppressing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

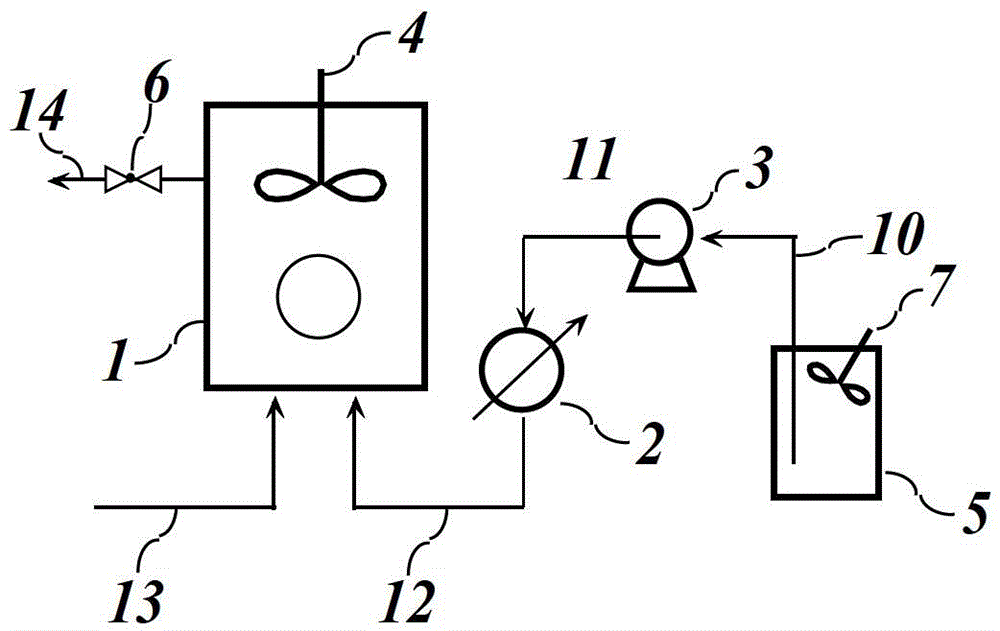

[0036] devices such as figure 1 As shown: the disperser 7 is used for high-speed shearing of the mixed liquid containing phase change materials, surfactants, nucleating agents and water. Fix the disperser 7 above the container 5 with a bracket, adjust the height of the disperser 7 so that the knife head of the disperser 7 extends into the liquid in the container 5, and the liquid in the container 5 passes through under the action of the booster pump 3 The suction line 10 and the discharge line 11 are sent to the heat exchanger 2, and the heat exchanger 2 is connected to the hydrator 1 through the liquid inlet line 12. There is an air inlet at the bottom of the hydrator 1, and the hydration gas passes through the air inlet line. 13 enters the hydrator 1, and there is a stirrer 4 in the hydrator 1, mainly to strengthen the mass transfer between the gas and the liquid and to enhance the phase change heat transfer in the hydration process, and to avoid the agglomeration of the for...

Embodiment 2

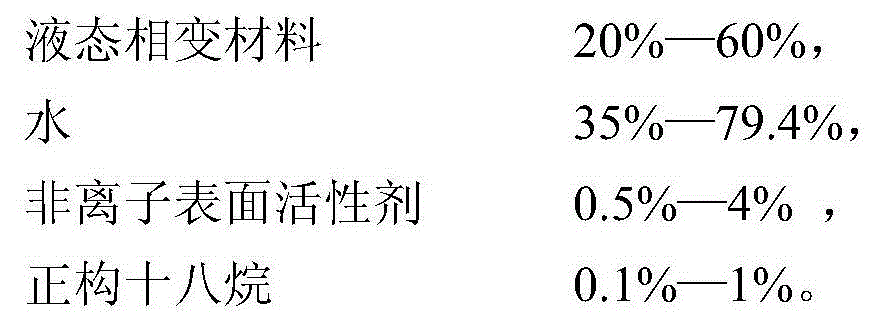

[0040] Select phase change material n-tetradecane, deionized water, surfactant span60 and tween60 and nucleating agent n-octadecane to make phase change material containing 35wt%, water 62.2wt%, surfactant 2wt%, The mixed solution of 0.8wt% nucleating agent, in which the mass ratio of span60 and tween60 is 1:2, the liquid mixing process is completed in container 5. Then place the container 5 containing the mixed solution in a constant temperature water bath at 30°C and let it stand for half an hour. After the temperature stabilizes, use the disperser 7 at a speed of 10,000 rpm to process it for one hour to obtain an emulsion of the phase change material and water. The emulsion is sent by the booster pump 3 to the heat exchanger 2 through the suction line 10 and the discharge line 11 at a flow rate of 4 mL / min. After cooling, the phase change material droplets in the emulsion are solidified, thereby forming small solid particles dispersed in water. slurry. The slurry enters th...

Embodiment 3

[0042] Select phase change materials n-tetradecane and n-pentadecane, deionized water, surfactant span60 and tween60 and nucleating agent n-octadecane to make phase change material containing 60wt%, water 35wt%, surface Active agent 4wt%, nucleating agent 1wt% mixed solution, wherein the mass ratio of n-tetradecane and n-pentadecane is 4:1, the mass ratio of span60 and tween60 is 1:2, this liquid mixing process Finished in container 5. Then put the container 5 containing the mixed liquid in a constant temperature water bath at 30°C and let it stand for half an hour. After the temperature stabilized, process it with the disperser 7 at a speed of 30,000 rpm for 20 minutes to obtain an emulsion of the phase change material and water. The emulsion is sent to the heat exchanger 2 through the suction line 10 and the discharge line 11 by the booster pump 3 at a flow rate of 2.5mL / min. After cooling, the phase change material droplets in the emulsion are solidified to form small solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com