Full-automatic assembling line for electric fuel pump cores

An assembly line, electric fuel pump technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed product accuracy, poor accuracy of manual assembly, low production efficiency, etc., and achieve product quality The effect of stability, high production efficiency and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

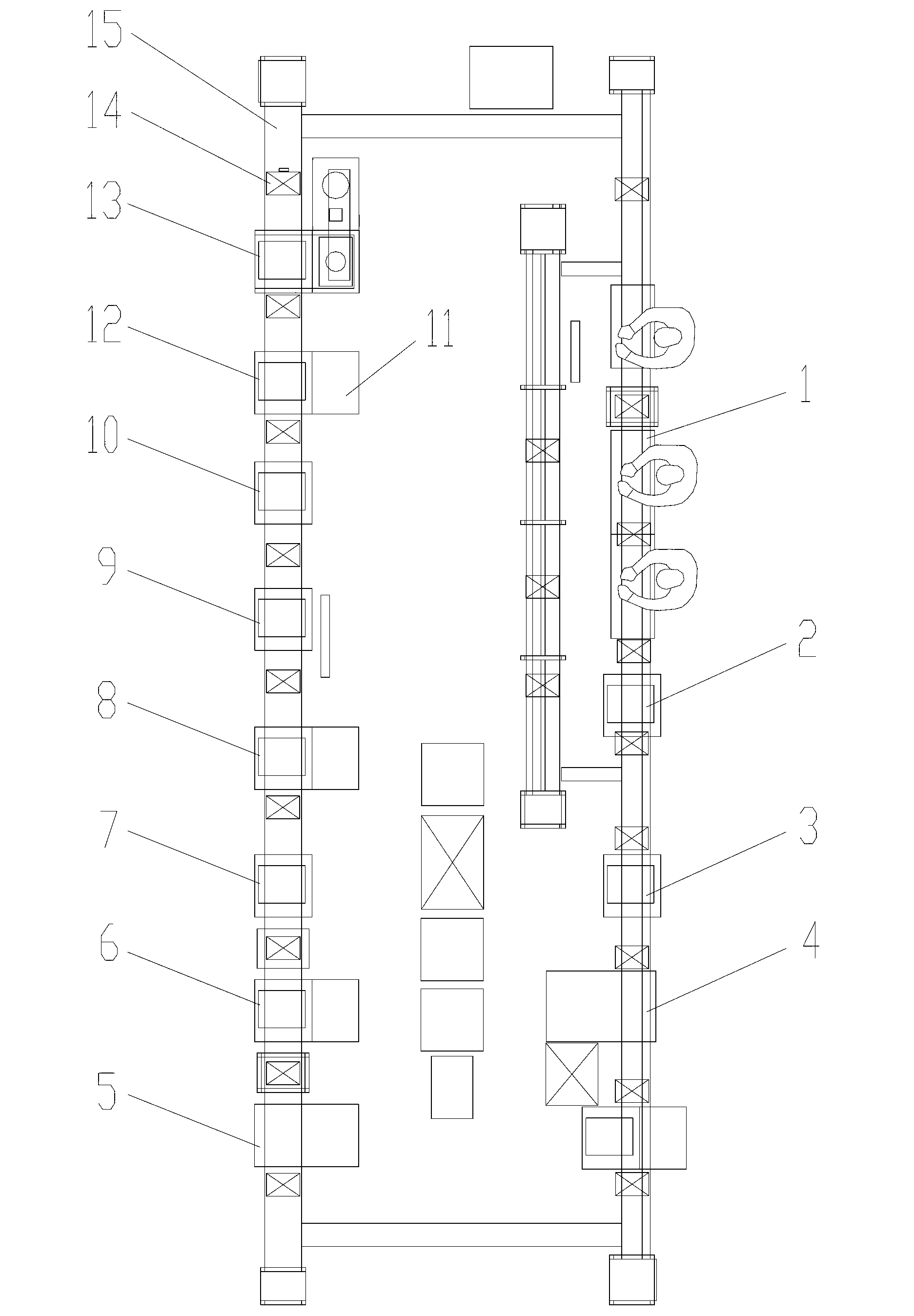

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0031] Please refer to figure 1, the production line adopts a circular conveyor line 15 to transport the accompanying tooling board 14, and the accompanying tooling board 14 is loaded with parts and assemblies that need to be assembled. The production line includes: loading and unloading station 1 in sequence according to the technological process, and automatic detection of missing and wrong loading Station 2, station 3 for pump casing assembly, station 4 for motor casing rotation, station 5 for installing magnetic tiles and support sheets, station 6 for magnetizing and magnetic flux detection, station 6 for installing armature and detecting the direction of rotation Station 7, press-fit oil bearing and oil outlet cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com