Method for producing cold-resistant plasticizer through industrial byproduct nylon acid

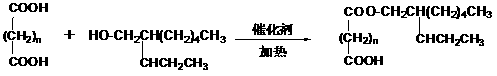

A technology of cold-resistant plasticizer and nylon acid, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., can solve problems such as waste pollution and environmental protection, achieve good compatibility, reduce costs, and be economical The effect of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

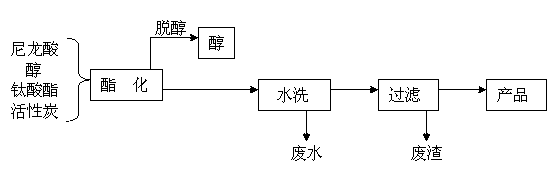

Method used

Image

Examples

Embodiment 1

[0031] 2.7kg of solid nylon acid, 6.4kg of 2-propylheptanol (the average molecular weight of nylon acid is 135, and the molar ratio of nylon acid to 2-propylheptanol is 1:2), put into the esterification kettle, and put into the catalyst tetrabutyl titanate 0.009kg of ester and 0.009kg of activated carbon are used to absorb oxygen and decolorize, stir and heat up. Control the esterification temperature at 170°C and the reaction time for 4 hours. After the reaction is complete, carry out distillation dealcoholization directly. The dealcoholization temperature is 175°C and the vacuum degree is 0.085MPa. , and finally filtered to obtain the product nylon acid bis(2-propylheptanol) ester.

Embodiment 2

[0033] 2.7kg of solid nylon acid, 7.0kg of 2-propylheptanol (the average molecular weight of nylon acid is 135, and the molar ratio of nylon acid to 2-propylheptanol is 1:2.1), put into the esterification kettle, and put into the catalyst tetramethyl titanate 0.010kg of ester and 0.010kg of activated carbon are used to absorb oxygen and decolorize, stir and heat up. Control the esterification temperature at 165°C and the reaction time for 4 hours. After the reaction is complete, carry out distillation dealcoholization directly. The dealcoholization temperature is 170°C and the vacuum degree is 0.09MPa. Wash with water, and finally filter to obtain the product nylon acid bis(2-propylheptyl alcohol) ester.

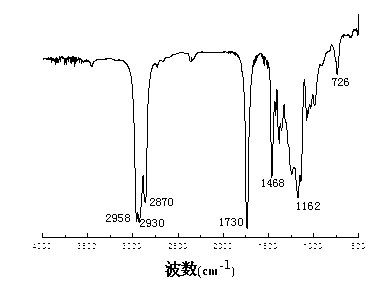

[0034] Tested by Zhejiang Jianye Chemical Co., Ltd., the product has the advantages of low volatility, extraction resistance, migration resistance, compatibility, processability, and low-temperature performance, and meets the processing and application requirements of PVC pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com