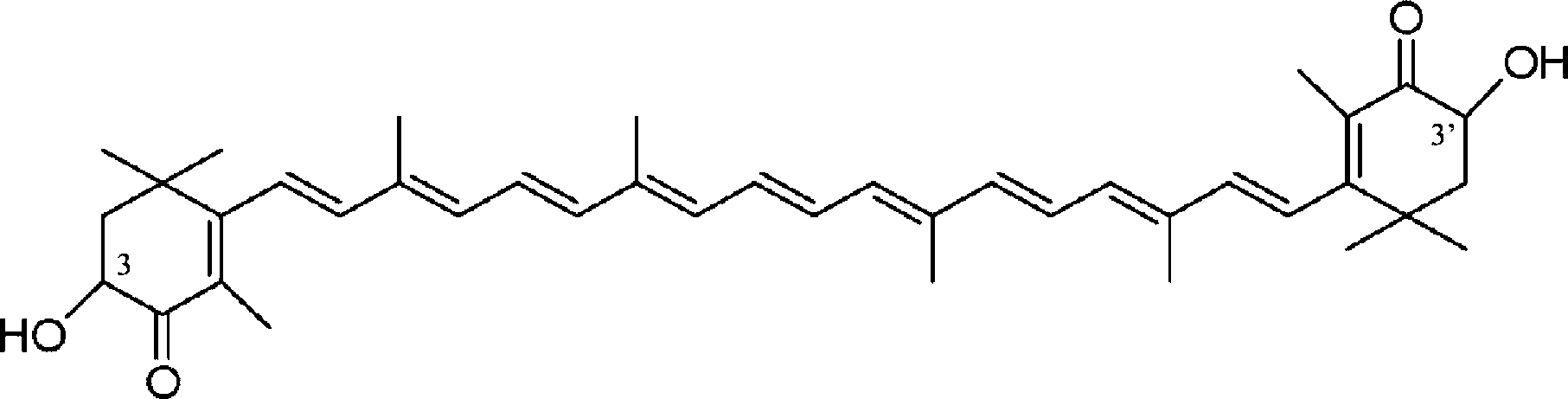

Method for preparing high-purity astaxanthin extract

An astaxanthin and extract technology, which is applied in the field of preparing high-purity astaxanthin extract, can solve problems such as inability to realize industrialized production, and achieve the effects of good promotion and application prospect, good health care function, and high development value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

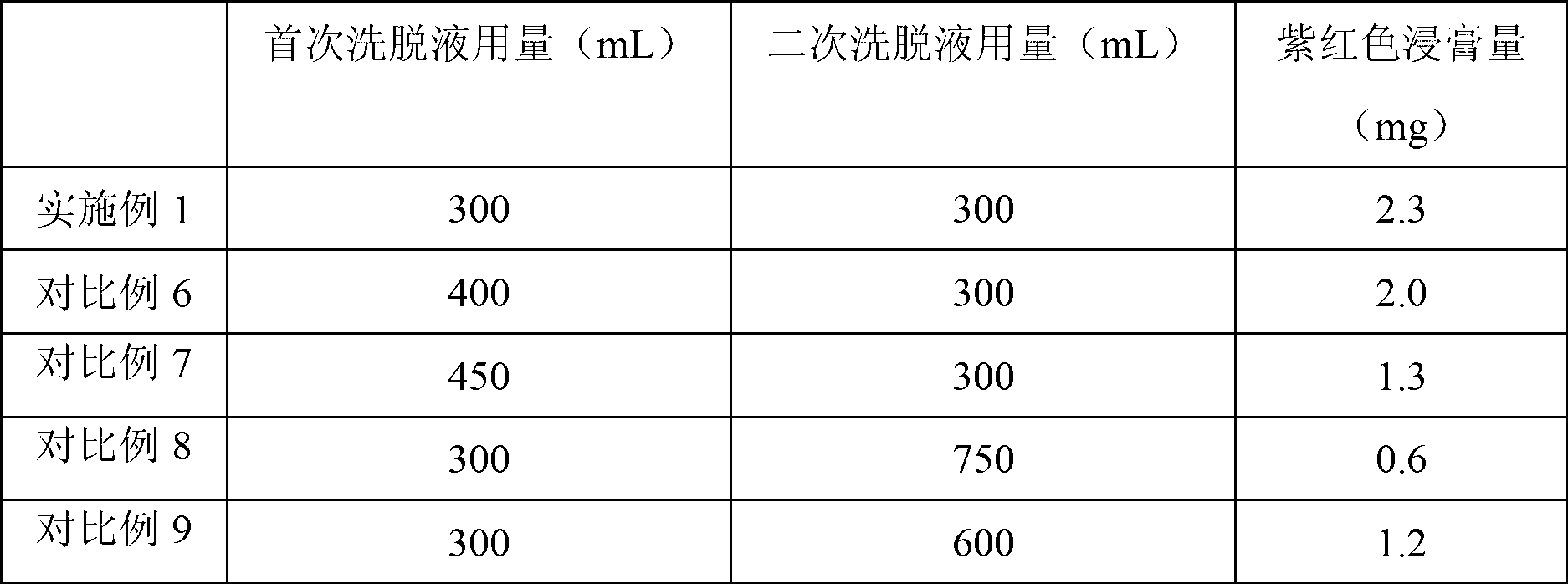

Embodiment 1

[0036] Embodiment 1, a kind of method for preparing high-purity astaxanthin extract, carry out following steps successively:

[0037] 1) Take 1mL of natural astaxanthin oil produced by Ningbo Honglong Biotechnology Co., Ltd. and dilute it with 5mL of absolute ethanol to obtain the diluted astaxanthin crude extract;

[0038] Take 1 mL of the diluted astaxanthin crude extract and add it to 4 mL of 12 mmol / L NaOH-absolute ethanol solution, mix well and place it in a dark place for saponification at room temperature (25°C) for 1 hour to obtain a saponified solution;

[0039] 2) Add the saponified solution obtained in step 1) into the dichloromethane-water solution (obtained by mixing 5mL of dichloromethane+5mL of water), mix thoroughly, and then let stand to separate and discard the upper liquid. The lower liquid was concentrated at 45°C under reduced pressure (0.09MPa) to obtain an extract (about 200mg);

[0040] 3) Dissolve the extract obtained in step 2) in 1 mL of n-hexane:ac...

Embodiment 2

[0062] Embodiment 2, a kind of method for preparing high-purity astaxanthin extract, carry out following steps successively:

[0063] 1) Take 0.1mL of natural astaxanthin oil produced by Ningbo Honglong Biotechnology Co., Ltd. and dilute it with 0.5mL of absolute ethanol to obtain a crude astaxanthin extract after dilution;

[0064] Take 0.1 mL of the diluted astaxanthin crude extract and add it to 0.4 mL of 6 mmol / L NaOH-absolute ethanol solution, mix well and place it in a dark place for saponification at room temperature (30°C) for 0.5 h to obtain a saponified solution;

[0065] 2) Add the saponified solution obtained in step 1) into a solution of dichloromethane-water (2mL+1mL), mix thoroughly, and then let stand to separate layers, and discard the upper layer liquid. The lower liquid was concentrated under reduced pressure at 40°C to obtain an extract;

[0066] 3) Dissolve the extract obtained in step 2) in 1 mL of n-hexane:acetone=4:1 (volume ratio) solution, and load a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com