Adhesive for silicon rod/silicon ingot slicing and method for preparing same

An adhesive and silicon ingot technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of broken silicon rods/silicon ingot slices, increased product rejection rate, and difficult to clean adhesives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. The adhesive is prepared according to the following composition ratio (mass percentage content):

[0020] 1. Group A components:

[0021] Epoxy resin E44 15%,

[0022] Epoxy resin E51 40%,

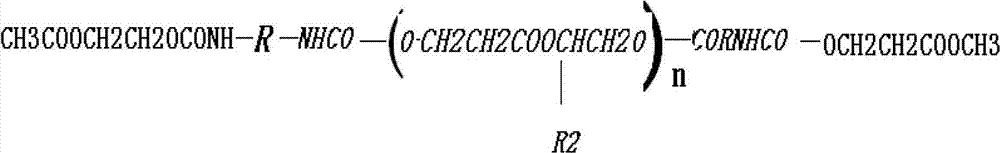

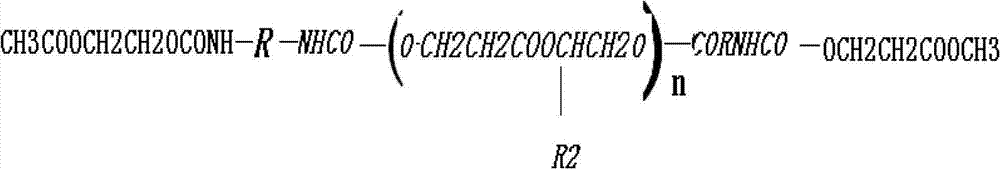

[0023] Acrylic polyurethane 30%,

[0024] Titanium dioxide 10%,

[0026] Imidazole 0.1%.

[0027] 2. Group B components:

[0028] Organotin Laurate 5%,

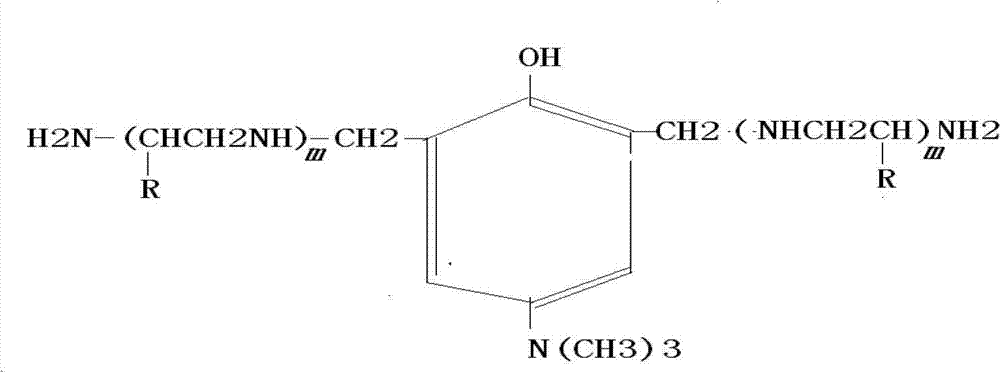

[0029] Polyamine 95%.

[0030] 2. Preparation method:

[0031] First mix the above-mentioned proportions of the components of Group A and Group B uniformly, and then mix the Group A and Group B uniformly in a mass ratio of 1:1 to obtain the adhesive of the present invention.

[0032] 3. The effect of the embodiment: the operating time at room temperature is 16 minutes, the initial curing time at room temperature is 5 minutes, the complete curing time is 5 hours, the bonding shear force is 18 MPa, and the cleaning time is 15 minutes.

Embodiment 2

[0034] 1. The adhesive is prepared according to the following composition ratio (mass percentage content):

[0035] 1. Group A components:

[0036] Epoxy resin E44 40%,

[0037] Epoxy resin E51 15%,

[0038] Acrylic polyurethane 30%,

[0039] Titanium dioxide 10%,

[0041] Imidazole 0.1%.

[0042] 2. Group B components:

[0043] Organotin Laurate 5%,

[0044] Polyamine 95%.

[0045] Two, this adhesive preparation method is the same as embodiment 1.

[0046] 3. The effect of the embodiment: the operating time at room temperature is 5 minutes, the initial curing time at room temperature is 52 minutes, the complete curing time is 5 hours, the bonding shear force is 19 MPa, and the cleaning time is 12 minutes.

Embodiment 3

[0048] 1. The adhesive is prepared according to the following composition ratio (mass percentage content):

[0049] 1. Group A components:

[0050] Epoxy resin E44 30%,

[0051] Epoxy resin E51 35%,

[0052] Acrylic polyurethane 25%,

[0053] Titanium dioxide 5%,

[0055] Imidazole 0.1%.

[0056] 2. Group B components:

[0057] Organotin Laurate 5%,

[0058] Polyamine 95%.

[0059] Two, this adhesive preparation method is the same as embodiment 1.

[0060] 3. The effect of the embodiment: the operating time at room temperature is 14 minutes, the initial curing time at room temperature is 53 minutes, the complete curing time is 5 hours, the bonding shear force is 17 MPa, and the cleaning time is 11 minutes.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap