Complex aluminum-based grease composition and preparation method thereof

A technology of lubricating grease composition and composite aluminum, applied in lubricating composition, petroleum industry and other directions, can solve the problem of extreme pressure and anti-wear performance to be improved, and achieve the effect of excellent anti-oxidation performance and excellent high-temperature bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

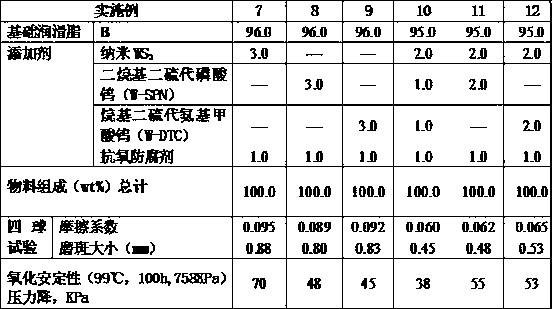

[0024] In order to further illustrate the technical effects of the present invention, 12 examples are provided below for illustration, wherein examples 1-6 are obtained by adding different additives on the basis of a base grease A, and the specific material composition, formula and test The results are shown in Table 1.

[0025] Examples 7-12 are obtained by adding different additives on the basis of another base grease B. The specific material composition, formula and test results are shown in Table 2.

[0026] in,

[0027] The preparation of base grease A is as follows: 100mm viscosity at 40°C 2 Add 30kg of refined mineral oil per s, 0.84kg of benzoic acid and 2.44kg of stearic acid into the reaction kettle, mix and heat to 80-90°C, keep stirring until the acid is completely dissolved, add 1.73kg of trimer aluminum oil solution, and heat to 90-110°C, stirring and reacting for 40 minutes, heating to 190-200°C, keeping warm and stirring for 30 minutes, adding the remaining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com