Preparation method of quaternary xerogel

A xerogel, four-component technology, applied in the field of xerogel preparation, can solve the problems of limited application, fragility, high porosity, etc., to increase the application range, increase the density, and improve the molding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

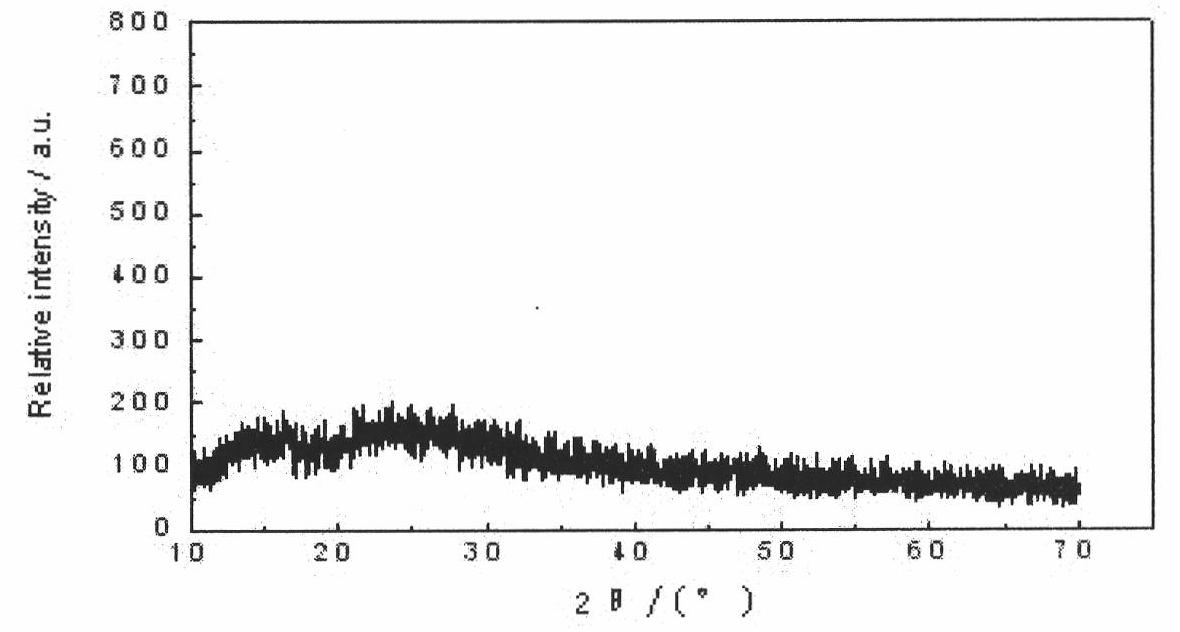

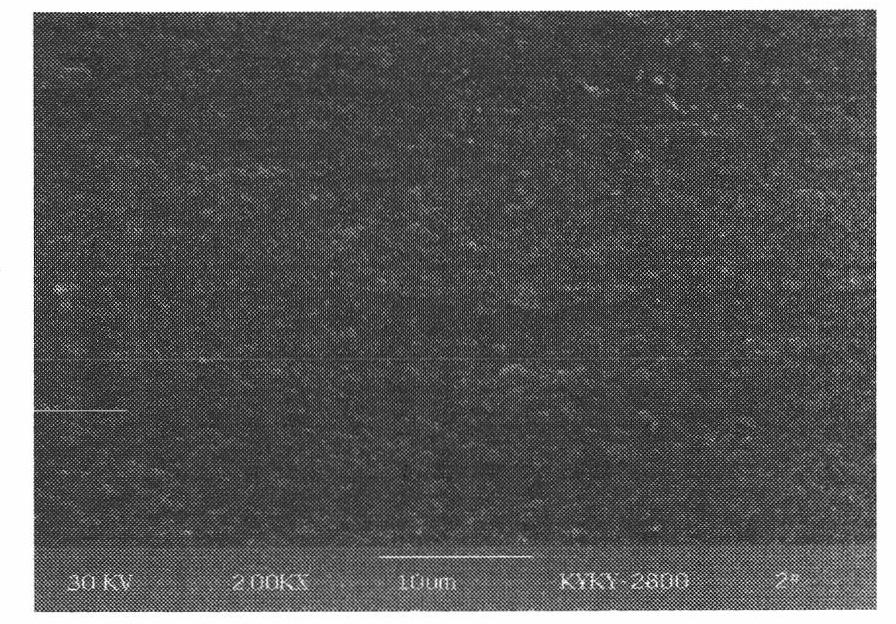

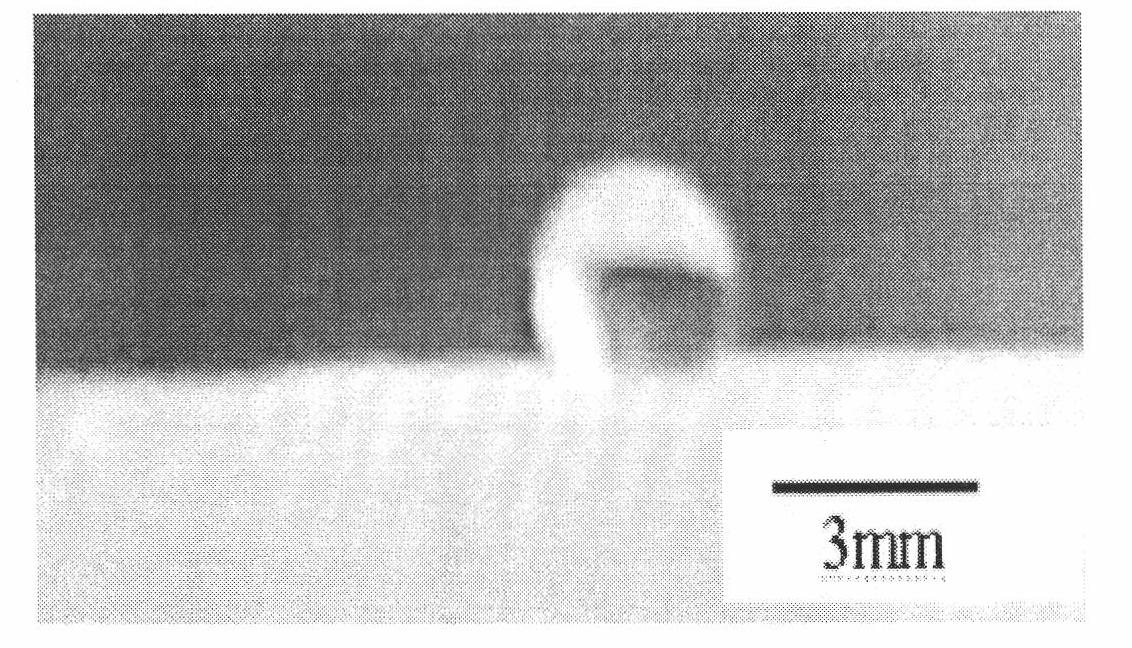

Image

Examples

Embodiment 1

[0014] The mass ratio of raw materials is zirconium oxychloride: aluminum isopropoxide: butyl titanate: ammonia water: tetraethyl orthosilicate: absolute ethanol=1~3:1~3:2~4:5~8:16~ 20: 90-110. Adjust the pH with dilute hydrochloric acid. Aluminum isopropoxide and zirconium oxychloride are used as one group of raw materials to be hydrolyzed together, and the pH value of the solution during hydrolysis is 4.0 to 4.5; ethyl orthosilicate and butyl tertate are used together as another group, and the pH value of the solution during hydrolysis is 2.5 to 3.0. Keep the temperature of the solution at 70-75°C, and keep stirring. After about 10-20 minutes, mix the two sets of solutions, and add dilute NaOH solution to the solution dropwise while stirring continuously, until a gel is formed.

Embodiment 2

[0016] The obtained gel was placed in a tetraethyl orthosilicate-absolute ethanol solution prepared at a volume ratio of 1:1 for aging for 15 hours, and the aging temperature was 60°C. Soak the aged gel in n-heptane for 24 hours at 70°C. Soak the soaked gel in trimethylchlorosilane for 12 hours, then take it out, and dry it at 50°C under normal pressure for 12 hours to obtain SiO 2 -TiO 2 -Al 2 o 3 -ZrO 2 Four-component dry gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com