Composite sol and method for preparing material for anti-radiation space suit by use of same

A composite sol and aerospace technology, applied in textiles and papermaking, fiber treatment, coating, etc., can solve the problems of decreased protective performance, formation of micropores, decreased protective effect, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

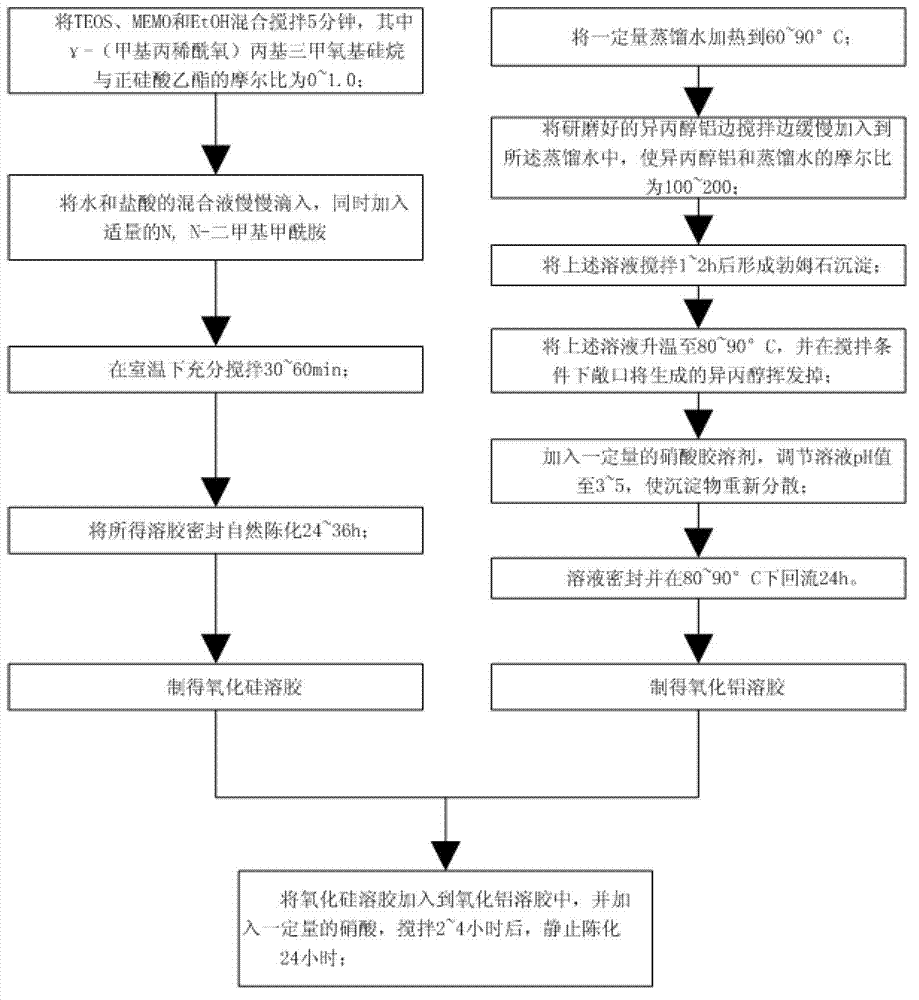

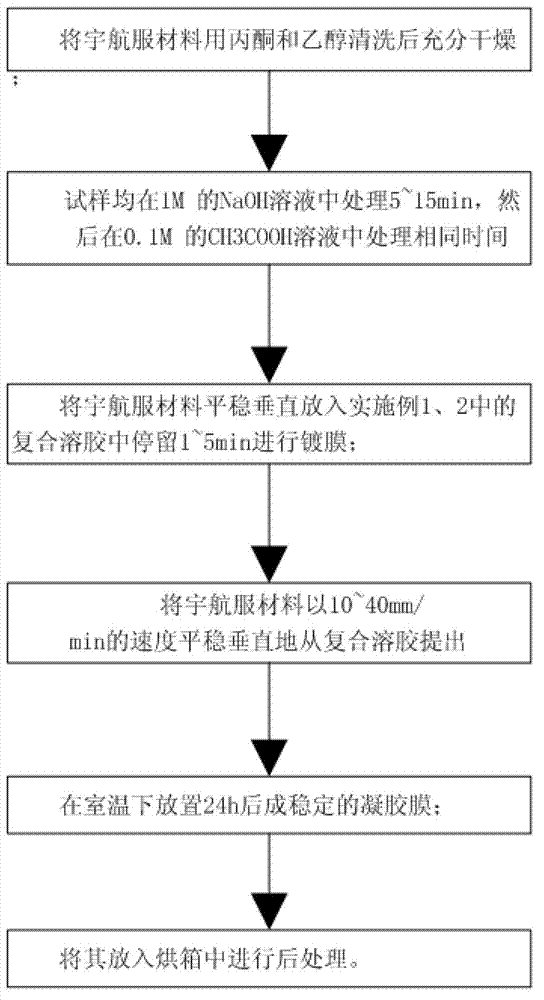

[0040] Embodiment 1, silica-alumina composite sol

[0041] It is composed of silica sol and alumina sol. The silica sol includes ethyl orthosilicate, γ-(methacryloyloxy)propyltrimethoxysilane, absolute ethanol, hydrochloric acid, N,N-dimethoxysilane Methylformamide, wherein the molar ratio of ethyl orthosilicate, γ-(methacryloyloxy)propyltrimethoxysilane, absolute ethanol, water, and hydrochloric acid is 1 / (0~1.0) / [16 ~20] / [6~10] / [0.01~0.03]. The alumina sol includes aluminum isopropoxide distilled water and nitric acid, wherein the molar ratio of aluminum isopropoxide to distilled water is 100 to 200, and the pH value of the alumina sol is 3 to 5.

Embodiment 2

[0043] This example is a special example of Example 1. The silica-alumina composite sol is composed of silica sol and alumina sol. The silica sol includes tetraethyl orthosilicate, γ-(methacryloyloxy)propyl Trimethoxysilane, absolute ethanol, hydrochloric acid, N,N-dimethylformamide, including ethyl orthosilicate, γ-(methacryloyloxy)propyltrimethoxysilane, absolute ethanol, water , The molar ratio of hydrochloric acid is 1 / 0.1 / 16 / 6 / 0.01. The alumina sol includes aluminum isopropoxide distilled water and nitric acid, wherein the molar ratio of aluminum isopropoxide to distilled water is 100, and the pH value of the alumina sol is 3.

Embodiment 3

[0045] This example is a special example of Example 1. The silica-alumina composite sol is composed of silica sol and alumina sol. The silica sol includes tetraethyl orthosilicate, γ-(methacryloyloxy)propyl Trimethoxysilane, absolute ethanol, hydrochloric acid, N,N-dimethylformamide, including ethyl orthosilicate, γ-(methacryloyloxy)propyltrimethoxysilane, absolute ethanol, water , The molar ratio of hydrochloric acid is 1 / 0.9 / 20 / 10 / 0.03. The alumina sol includes aluminum isopropoxide distilled water and nitric acid, wherein the molar ratio of aluminum isopropoxide to distilled water is 200, and the pH value of the alumina sol is 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com