Controllable doping of SiC single crystal low-dimensional nano material

A low-dimensional nano- and single-crystal technology, applied in the growth of polycrystalline materials, single crystal growth, single crystal growth, etc., can solve the problems of controllable doping of SiC single crystal low-dimensional nanomaterials, which have not been reported, and achieve high yield High, smooth surface, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

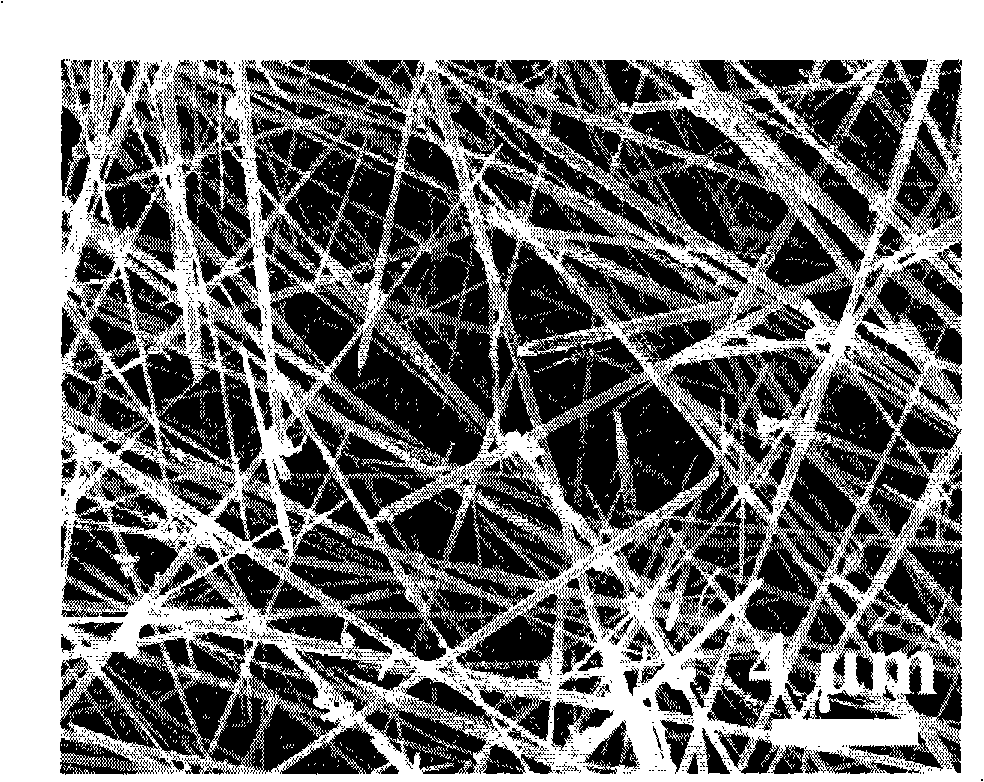

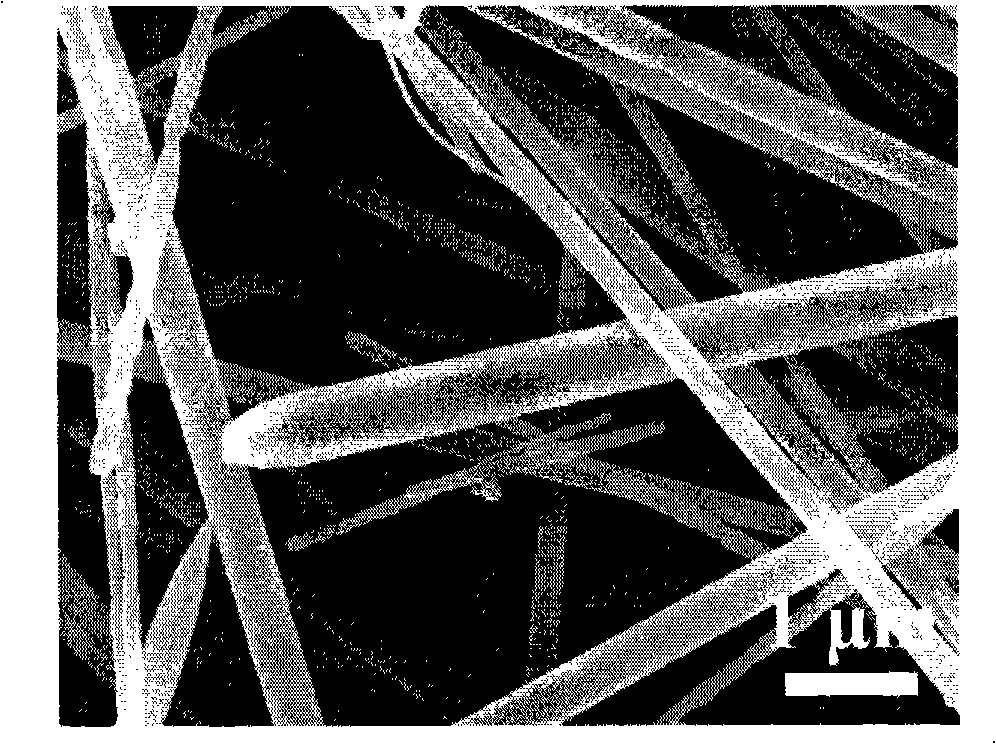

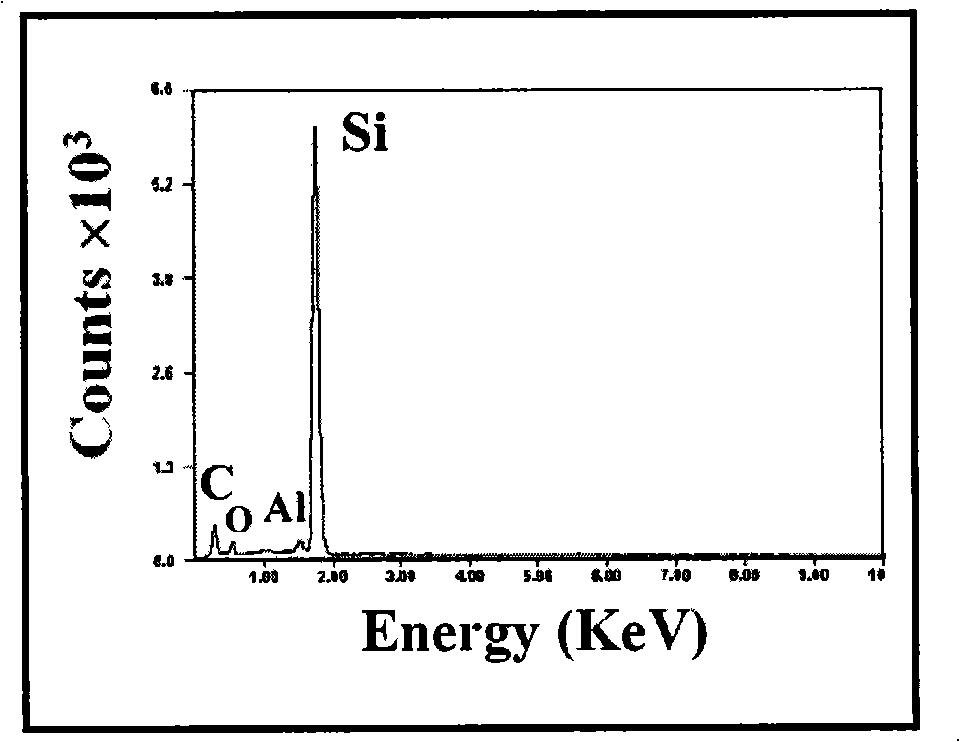

[0034] Weigh a total of 10 g of the initial raw material (5wt% aluminum isopropoxide + 95wt% polysilazane), put it into a nylon resin ball mill jar and planetary ball mill it for 12 hours, mix it evenly, place it in a 99 alumina ceramic crucible, and place it in a 0.1MPa N 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder was used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, then the SiAlCN powder obtained after the high-energy ball milling was placed in a 99 alumina ceramic crucible, and placed in a 0.1MPa flow (200ml / min) Ar atmosphere under the protection of In the tube furnace, the temperature was raised from room temperature to 1450 °C at 10 °C / min for high-temperature pyroly...

Embodiment 2

[0036] Weigh a total of 10 g of the initial raw material (0.2wt% aluminum isopropoxide+99.8wt% polysilazane), put it into a nylon resin ball mill jar for planetary ball milling for 12 hours, mix it uniformly and put it in a 99% alumina ceramic crucible. 0.1MPa N 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder was used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, then the SiAlCN powder obtained after the high-energy ball milling was placed in a 99 alumina ceramic crucible, and placed in a 0.1MPa flow (200ml / min) Ar atmosphere under the protection of In the tube furnace, the temperature was raised from room temperature to 1450 °C at 10 °C / min for high-temperature pyrolysis, kept for...

Embodiment 3

[0038] Weigh a total of 10g of the initial raw material (1wt% aluminum isopropoxide + 99wt% polysilazane), put it into a nylon resin ball mill jar and planetary ball mill it for 12 hours, mix it evenly, place it in a 99 alumina ceramic crucible, and place it in a 0.1MPa N 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder was used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, then the SiAlCN powder obtained after the high-energy ball milling was placed in a 99 alumina ceramic crucible, and placed in a 0.1MPa flow (200ml / min) Ar atmosphere under the protection of In the tube furnace, the temperature was raised from room temperature to 1450 °C at 10 °C / min for high-temperature pyrolys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com