Method for separating neptunium from uranium product by TEVA-UTEVA extraction chromatographic column

A chromatographic column and product technology, applied in the field of nuclear fuel cycle, can solve the problems of complex separation process and low recovery rate, and achieve the effects of simple separation process, small column volume, and reduced time required for separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

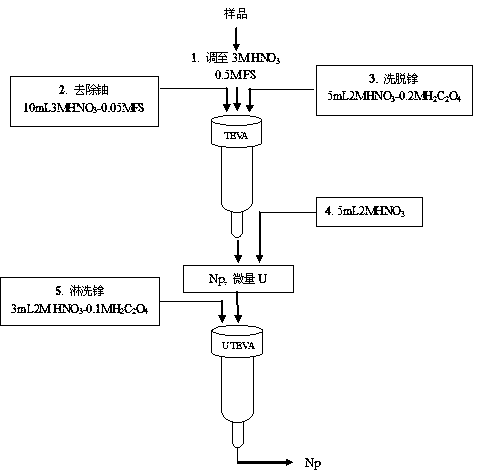

[0039] as per figure 1As shown in the schematic diagram of the separation process, take 1 mL of uranium sample, adjust the concentration of nitric acid to 2 mol / L, then add 0.1 mL of 0.5 mol / L ferrous sulfamate (FS) solution, let it stand for 5 to 10 minutes, and reduce neptunium to Np(Ⅳ); put the sample after acid adjustment and price adjustment on TEVA extraction column, use 10mL1.5mol / LHNO 3 -0.05mol / L FS mixed solution to rinse uranium; then use 5mL2mol / L HNO 3 -0.2mol / L H 2 C 2 o 4 The neptunium in the TEVA extraction chromatography column was eluted, and the eluent was collected. Add 5mL2mol / L HNO to the eluent 3 After shaking well, put the solution on the UTEVA extraction chromatography column, and use 3mL2mol / L HNO 3 -0.1mol / L H 2 C 2 o 4 The distribution of uranium on the UTEVA column is basically not affected by elution, while Np(IV) has a strong elution ability, but the elution effect on U(VI) is poor, so that neptunium can be separated from a large amount ...

Embodiment 2

[0041] Take 1mL of uranium sample, adjust the acidity of nitric acid to 3mol / L, then add 0.1mL of 0.5mol / L ferrous sulfamate (FS) solution, let it stand for 5-10 minutes, and reduce neptunium to Np(IV); The sample after acid adjustment and price adjustment is put on the TEVA extraction column, using 10mL3mol / L HNO 3 -0.05mol / LFS mixed solution to wash uranium; then use 5mL2mol / L HNO 3 -0.2mol / L H 2 C 2 o 4 The neptunium in the TEVA extraction chromatography column was eluted, and the eluent was collected. Add 10mL2mol / L HNO to the eluent 3 After shaking well, put the solution on the UTEVA extraction chromatography column, and use 3mL2mol / L HNO 3 -0.1mol / L H 2 C 2 o 4 The distribution of uranium on the UTEVA column is basically not affected by elution, while Np(IV) has a strong elution ability, but the elution effect on U(VI) is poor, so that neptunium can be separated from a large amount of uranium.

Embodiment 3

[0043] In order to verify the effect of the present invention for separating neptuntium in a large amount of uranium, this example prepared a certain ratio of simulated neptuntium separation in uranium products before the experiment.

[0044] (1) Configuration of simulated samples

[0045] The simulation sample is prepared according to the ratio of uranium, neptunium and plutonium in the uranium product, and the sample matrix solution is 3.0mol / L HNO 3 , whose composition is shown in Table 2.

[0046] Table 2 Composition of simulated samples

[0047]

[0048] (2) Determination of simulated samples

[0049] Take 1mL sample, add 0.1mL of 0.5mol / L ferrous sulfamate (FS) solution, let it stand for 5-10 minutes, and reduce neptunium to Np(IV); put the sample after acid adjustment and price adjustment on TEVA extraction column, use 10mL3mol / LHNO 3 -0.05mol / LFS mixed solution to wash uranium; then use 5mL2mol / LHNO 3 -0.2mol / LH 2 C 2 o 4 The neptunium in the TEVA extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com