An alloy preparation method for improving the microstructure of 2618 aluminum alloy

A technology of microstructure and aluminum alloy, applied in the field of alloy preparation to improve the microstructure of 2618 aluminum alloy, can solve the problems of inclusion particles, large component segregation, deterioration of alloy properties, etc., to improve cold and hot working properties, reduce coarse The effect of dendrite formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

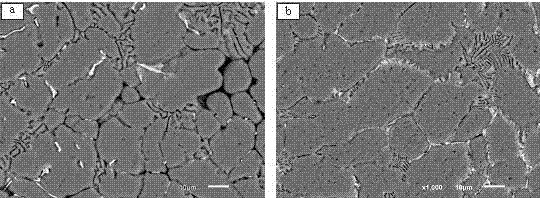

[0029]Embodiment 1: The traditional Al-50wt%Cu master alloy is smelted to prepare 2618 aluminum alloy, the design composition is 2.3Cu-1.6Mg-1.1Fe-1.1Ni-Bal.Al (mass fraction), and the addition of the master alloy is 4.6 wt.%; First, preheat the graphite crucible to a red-hot state (550°C) with a crucible resistance furnace, and then heat up to 720-750°C to commercially pure aluminum (99.7wt.%Al), Al-50wt.%Cu, Al- The 10wt.%Fe, Al-10wt.%Ni and Al-25wt.%Mg master alloys are completely melted, stirred to make them evenly mixed, and left to stand to control the temperature of the alloy melts at 660°C and 720°C respectively for casting.

Embodiment approach 2

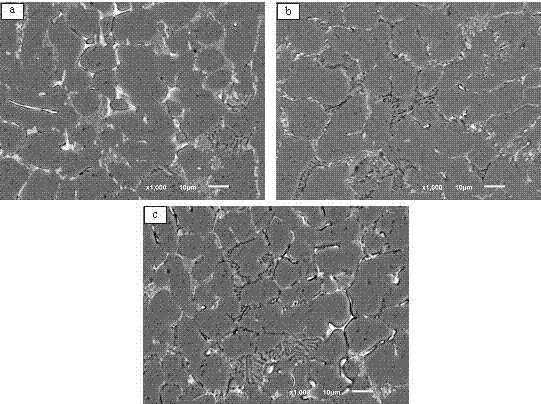

[0030] Embodiment 2: Al-90Cu (Al-90wt%Cu) alloy powder is used as the source of Cu element in 2618 aluminum alloy, and the design composition is 1.9-2.5Cu-1.6Mg-1.1Fe-1.1Ni-Bal.Al, Cu content 1.9%, 2.3%, and 2.5% (mass fraction); firstly, use a crucible resistance furnace to preheat the graphite crucible to a red-hot state (540°C), and then heat it up to 720-750°C to add industrial pure aluminum, Al-10wt.% The Fe, Al-10wt.%Ni and Al-25wt.%Mg master alloys are completely melted, stirred to make them evenly mixed, and left to control the temperature of the alloy melt at 668-688°C, adding 2.11 wt.%, 2.56, 2.78 wt.% alloy powder, stir quickly until the powder is completely melted and strictly control the stirring time within 60S, and immediately cast it into a steel mold with a cavity size of φ12×120mm preheated to 150°C, and the pouring temperature is 660°C.

[0031] Implementation scheme three: this scheme is adopted as a comparison. Al-90Cu (Al-90wt%Cu) alloy powder is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com