A safety protection method for anode lift of slot control machine

A technology of slot control machine and anode, which is applied in the field of electrical control, can solve problems such as hidden safety hazards, serious accidents in slot drawing or slot pressing, economic losses, etc., and achieve the effects of safe and stable operation guarantee, improved reliability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

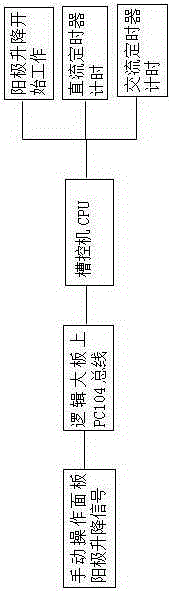

[0034] purpose of the invention

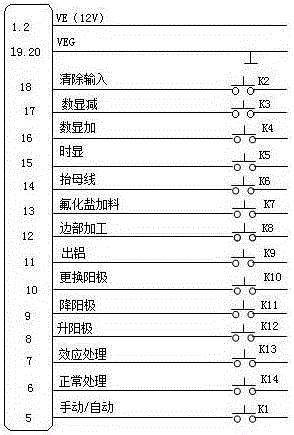

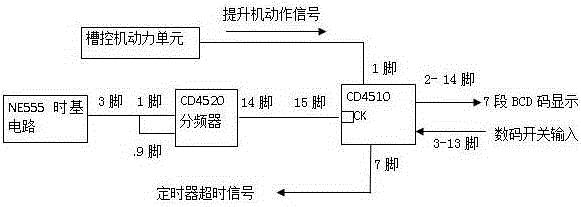

[0035] When the slot control machine is performing process control, you can set the slot control machine to work in automatic mode or manual mode through the switch button on its panel. According to the requirements of the electrolysis process, in order to make the cell voltage quickly reach the required target value, it is often necessary to manually adjust the anode to achieve the goal. However, there is no monitoring equipment and technical monitoring measures to assist in this operation process. Only relying on manual control of the anode lifting time, this method has great potential safety hazards. If the manual anode is misoperated or the contactor appears Adhesion failure, at this moment the anode cannot be controlled at all, which will cause serious accidents of groove pulling or groove pressing, and bring huge economic losses. In order to improve the safety and reliability of the tank control machine and eliminate the potential saf...

Embodiment

[0049] This technical method is simple and not restricted by the working environment. It makes up for the defects of the tank control system in the manual anode lifting operation, and reduces the probability of slotting accidents in the anode lifting operation. After nearly half a year of actual operation, the system is reliable. The permanent design has withstood the test of complex industrial environments such as strong electromagnetic interference and power frequency signal interference. The safety of manual anode lifting operation has been greatly improved, providing a strong guarantee for the safe and stable operation of electrolysis production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com