Splitting twisting-boosting type vortex spinner

A vortex spinning and beam splitting technology, which is applied in the field of textile processing, can solve the problems of reducing the stiffness of fibers, making fibers difficult to vortex into yarns, and poor fiber cohesion, so as to achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing

[0015] see Attachment

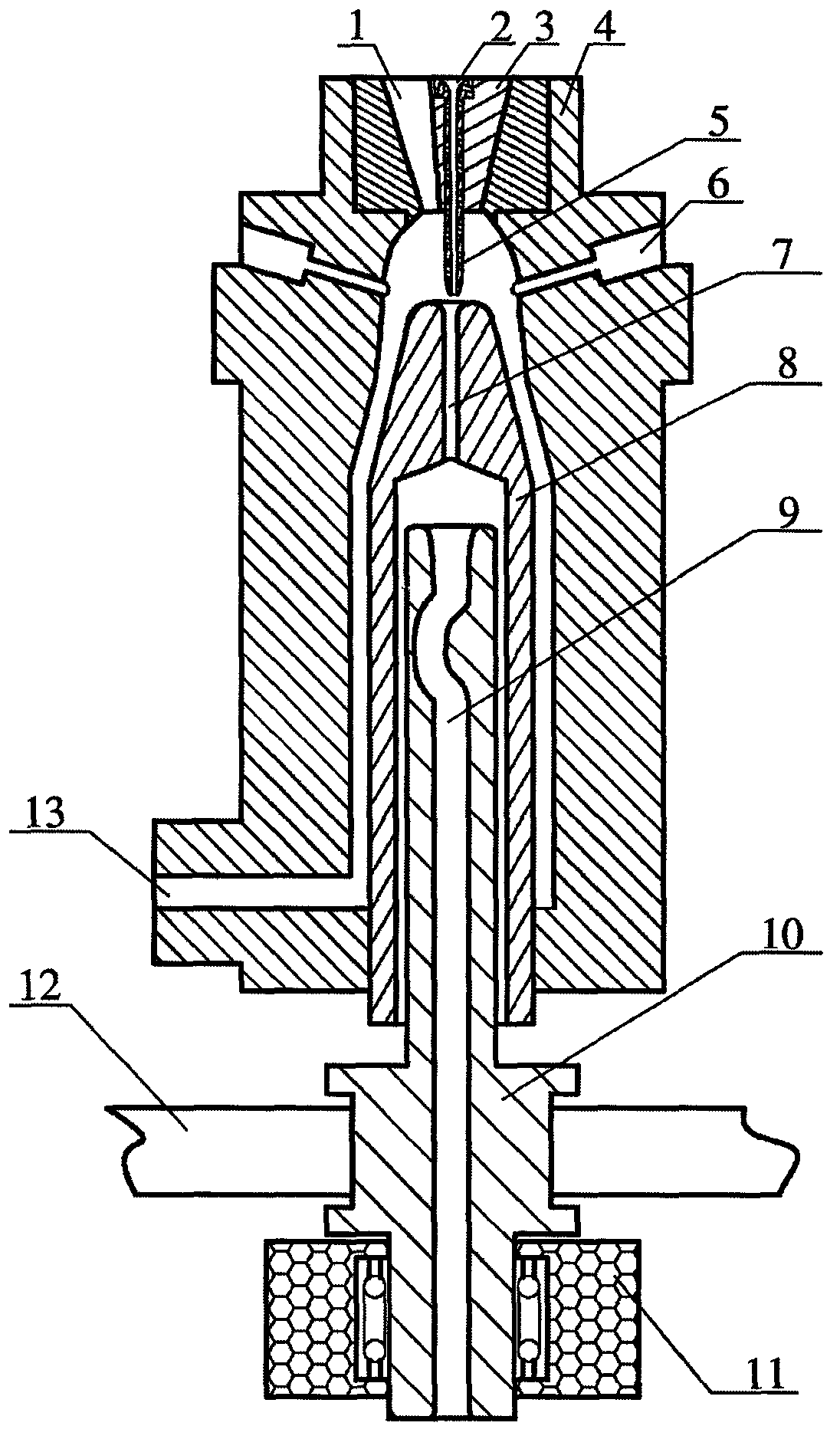

[0016]The beam-splitting twist-assisted vortex spinning device is composed of an outer tube 4, a guide pin holder 3, a guide pin 5, a fiber delivery channel 1, a stationary spindle 8, and a twist aid. The outer tube 4 is provided with four air inlet channels 6 and air outlets 13; the fiber flow guide composed of the guide pin 5 and the guide pin holder 3 is arranged on the outer tube 4, and the guide pin holder 3 is provided with a vertical channel hole, the guide pin 5 has a through beam splitting channel 2, the guide pin 5 is inserted into the vertical through hole in the holder 3, the guide pin 5 and the holder 3 are closely matched, the beam splitting channel 2 and the static ingot The yarn channel 7 in 8 is on the same axis; the lower end of the stationary spindle 8 is provided with a spindle cavity, and the twist aid is composed of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com