High-strength quick release steel pipe bracket system and its construction method

A steel pipe support and system technology, applied in the field preparation of pillars and building components, construction, etc., can solve the problem that the forces of inclined members are not on the same axis, the centerlines of the members cannot meet at one point, and cannot adapt to different models. Number combination and other problems, to achieve the effect of improving speed and accuracy, high rigidity, and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

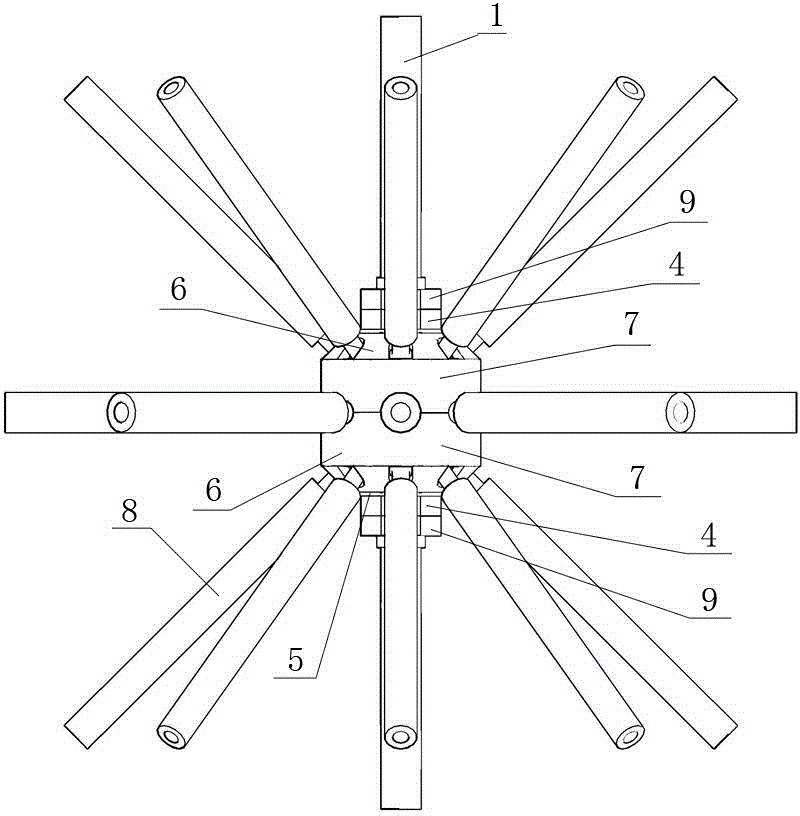

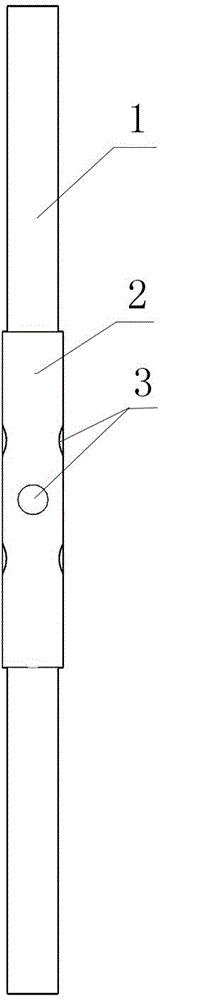

[0040] Such as figure 1 As shown, the high-strength quick-release steel pipe support system of the present invention consists of a main riser 1, a casing 2, three pin cores 3, two set nuts 4, two gaskets 5, two outer fasteners 6, and two inner fasteners. Fastener 7, several connecting rods 8 with ball ends at both ends and two lock nuts 9.

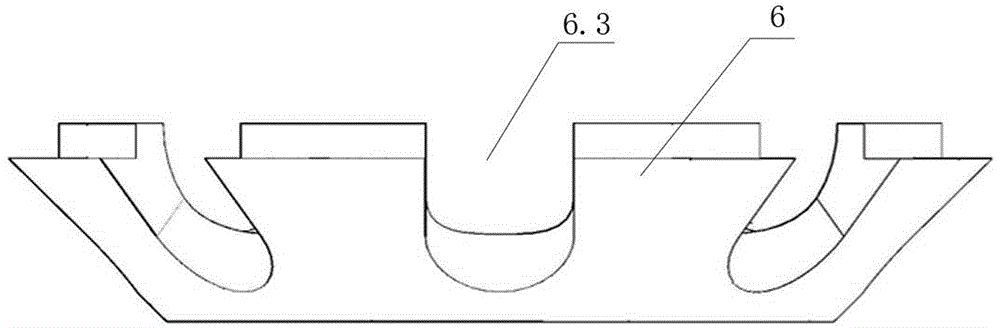

[0041] Such as figure 1 , figure 2 As shown, both ends of the casing 2 are provided with external threads. The casing 2 is sleeved on the outside of the main standpipe 1 in static fit, and fixed on the main standpipe 1 by three pin cores 3 . A set nut 4 is screwed on the outer thread of the lower end of the casing 2 , and the sleeve 2 is sequentially socketed with a gasket 5 , an outer fastener 6 and an inner fastener 7 above the set nut 4 . An inner fastener 7 , an outer fastener 6 and a spacer 5 are sequentially and repeatedly socketed symmetrically on the above three parts. A set nut 4 is screwed on the external thread of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com