High-speed direct-drive terrestrial heat generating system

A geothermal power generation and high-speed motor technology, applied in geothermal energy systems, geothermal energy power generation, electric components, etc., can solve the problems of complex structure, low efficiency of geothermal generators, environmental pollution, etc., achieve high integration, reduce volume, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

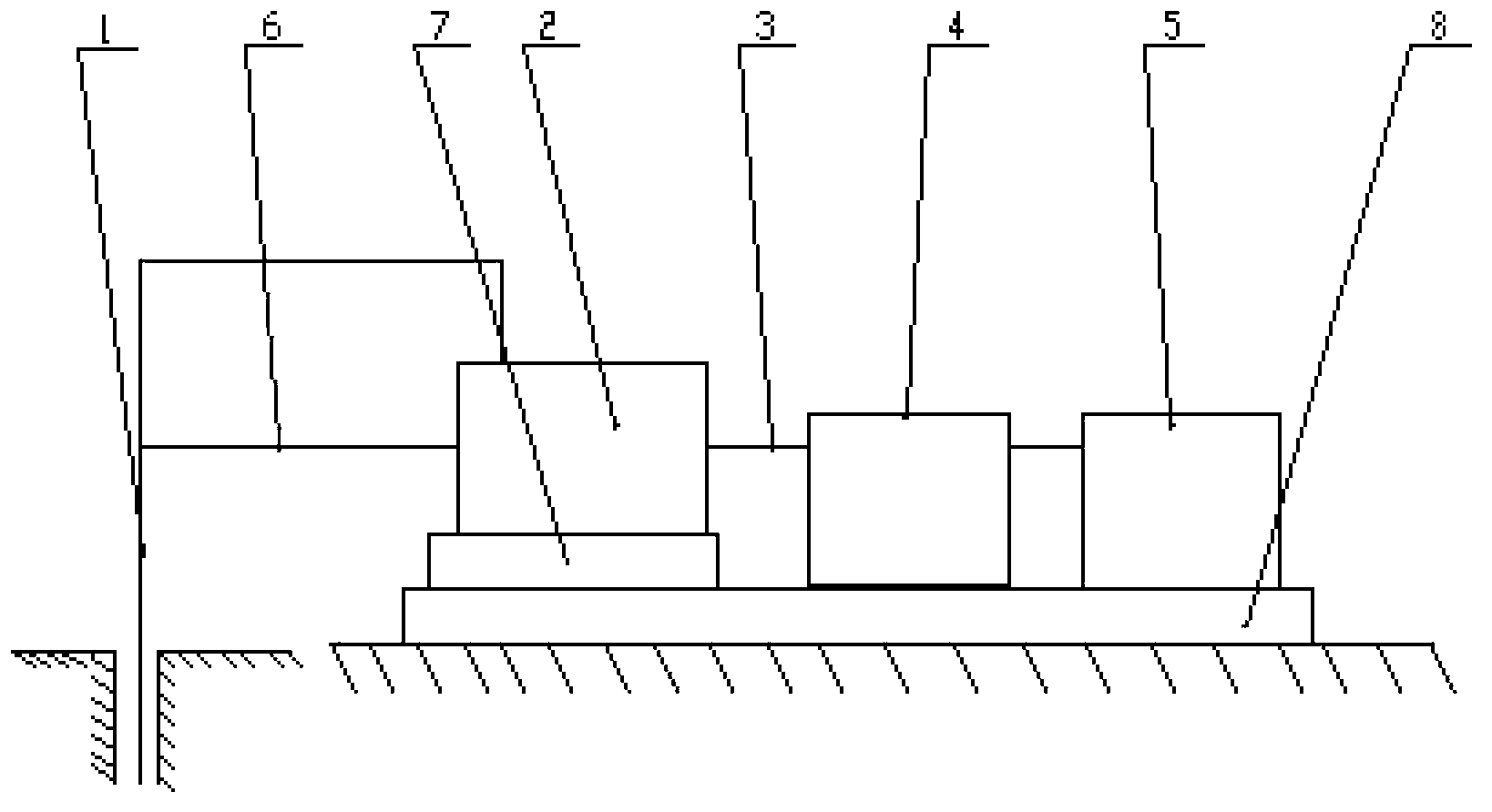

[0027] see figure 1 , a high-speed direct-drive geothermal power generation system, including a heat-resistant pipe 1 connected to underground hot dry rock at one end, and the other end of the heat-resistant pipe 1 is connected to the air inlet of the driving part 2, and the driving part 2 passes through a thin-walled sleeve coupling 3 is connected to the high-speed motor part 4, the high-speed motor part 4 is connected to the transformer 5, one end of the cooling water pipe 6 is connected to the air outlet of the driving part 2, and the other end is connected to the heat-resistant pipe 1, and the driving part 2 is installed on the overall test bench through the installation platform 7 8 on. The thin-wall sleeve coupling 3 realizes torque transmission by connecting the first step 14 and the second step 29 through interference.

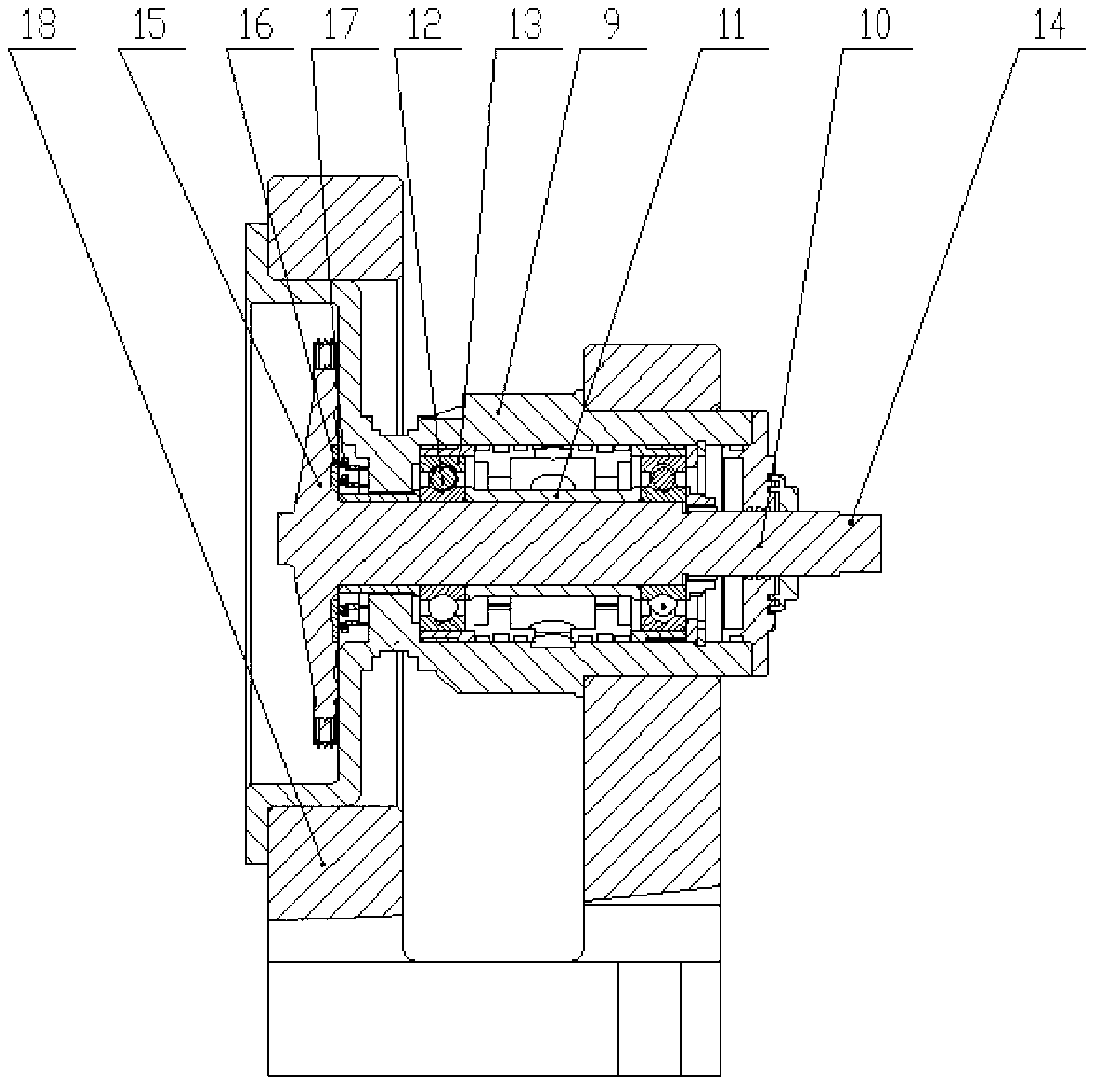

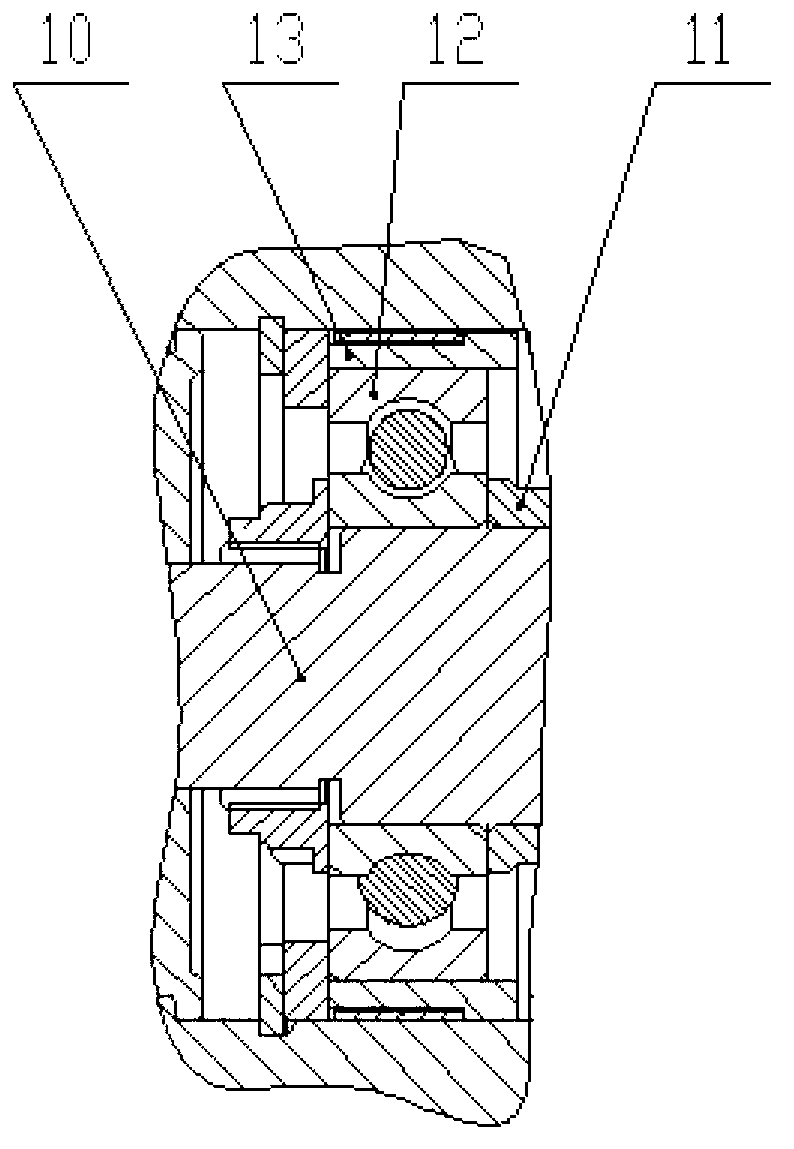

[0028] see figure 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com