Low-water-sucking water pump

A low water absorption and water pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of reduced service life, inability to pump water, and easy burnout of the motor, so as to improve the service life, ensure safety, and improve the utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

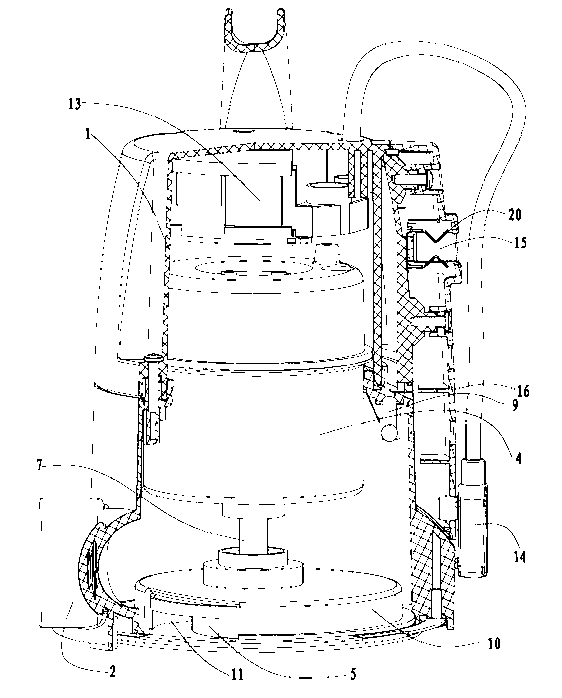

[0024] Such as figure 1 , figure 2 , image 3 As shown, the low-suction water pump provided by the present invention includes a pump casing 1, a first water outlet 2, a water inlet 3, a motor 4 and an impeller 5, and the first water outlet 2 is arranged on one side of the pump casing 1, and the The impeller 5 is fixed on the rotating shaft 7 of the motor 4, and a base 6 is fixed on the bottom of the pump housing 1, and the base 6 and the pump housing 1 form a pump chamber 8, and the motor 4 and the impeller 5 are placed in the pump chamber 8, an exhaust valve device 9 with a steel ball is provided on the pump casing 1, the water inlet 3 is provided on the base 6 below the position of the impeller 5, and a shroud 10 is provided on the upper part of the impeller 5, Such as Figure 4 Said, the wind deflector 10 passes through the rotating shaft 7 and achieves a sealing arrangement with the rotating shaft 7 through a sealing ring 19, and the wind deflector 10 and the base 6 fo...

Embodiment 2

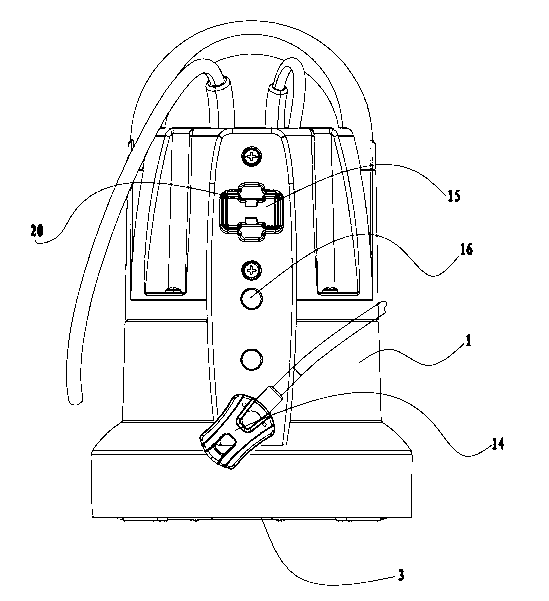

[0027] Such as Figure 5 As shown, the general structure of this embodiment is the same as that of Embodiment 1, except that a controller 13 is provided above the motor 4 in the pump chamber 8, and a water level sensor 14 is provided on the pump casing 1. The water level sensing head 14 is electrically connected with the controller 13; on the side of the pump housing 1, an induction head socket 15 and three induction head positioning jacks 16 capable of cooperating with the water level induction head 14 are respectively provided, and the induction head socket 15 A stainless steel sheet 20 for short-circuiting the sensing head is arranged inside, and the positioning jack 16 of the sensing head can be determined according to the requirements of specific embodiments.

[0028] When the water pump needs to be manually operated during work, the water level sensor head 14 can be inserted into the sensor head socket 15 to realize the manual control of the water pump startup function...

Embodiment 3

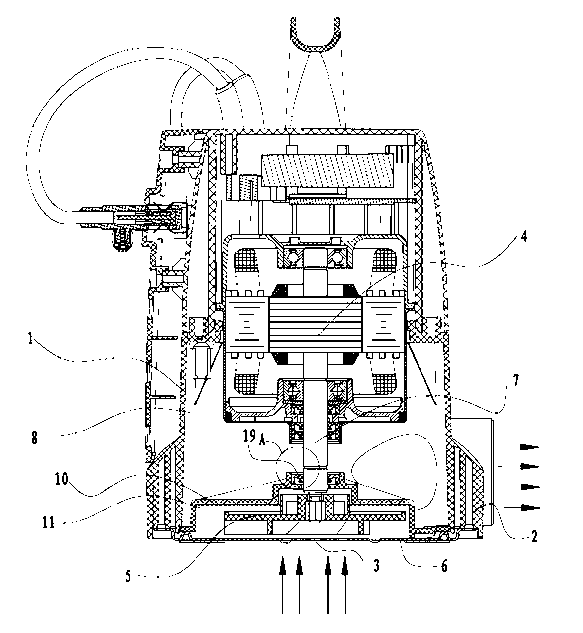

[0030] Such as Figure 6 , Figure 7 As shown, the general structure of this embodiment is the same as that of Embodiment 2, the difference is: in order to enable the water flow to be quickly thrown out from the nozzle 10, the inner wall of the nozzle 10 is provided with a first vortex groove 17 The opening at one end of the first vortex groove 17 corresponds to the water inlet 3 to form a volute, and the opening at the other end of the first vortex groove 17 is the second water outlet 12, which is smaller than the diameter of the opening at one end corresponding to the water inlet 3 and the diameter of the second water outlet. The other end corresponding to the second water outlet 12 mentioned above is open.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com