Method for adjusting primary mirror optical axis to be perpendicularly to horizontal axis by using laser tracker

A laser tracker, horizontal axis technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of large reference error of the optical axis of the main mirror, reduced accuracy, complicated operation procedures, etc., to improve work efficiency and accuracy, Avoid complicated processes and avoid the effect of complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

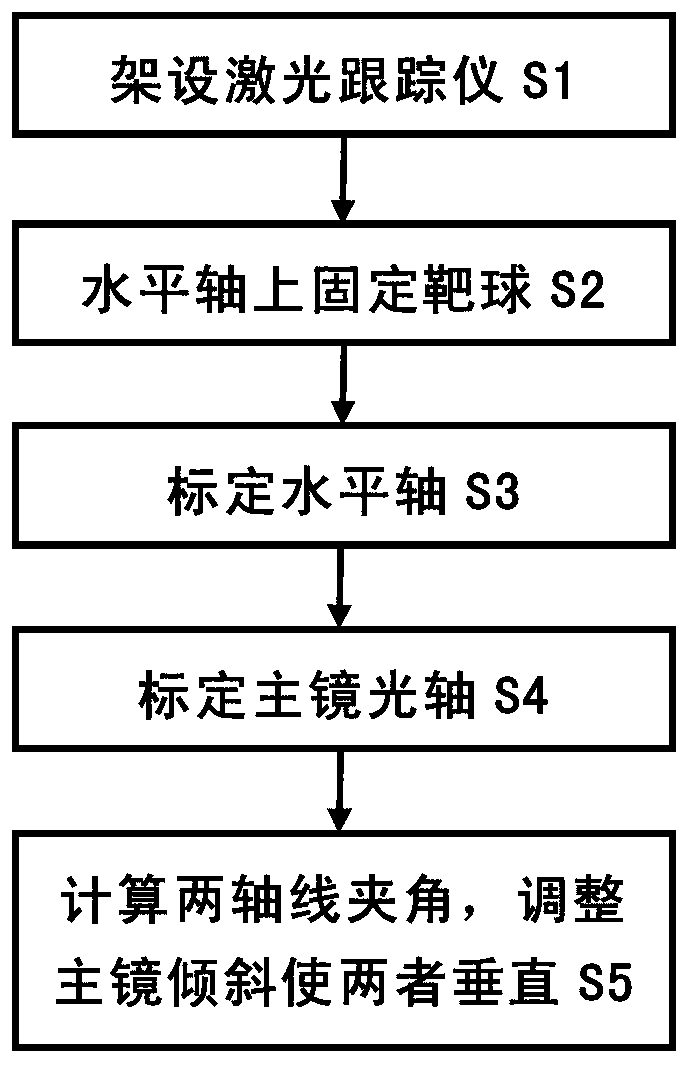

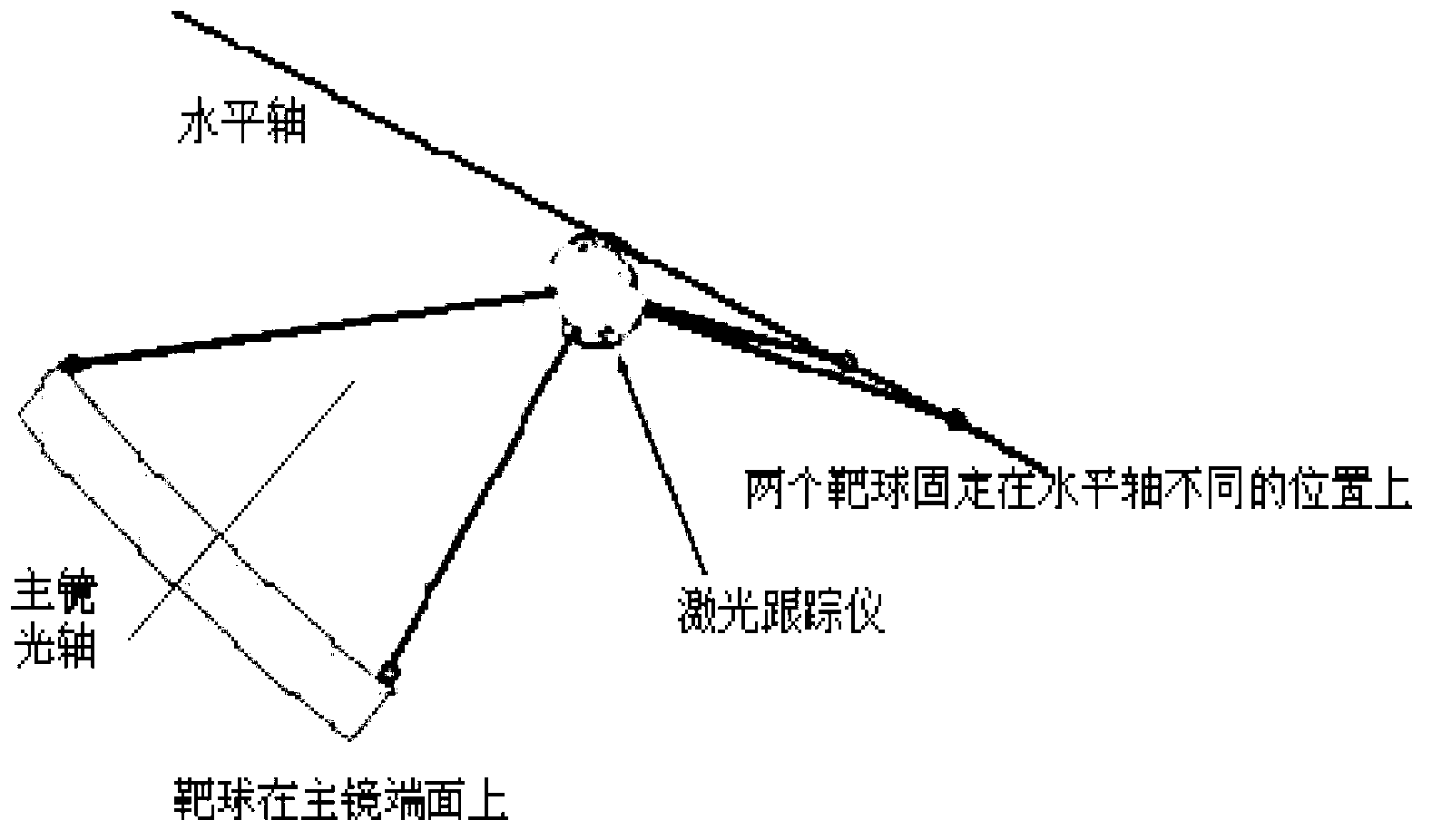

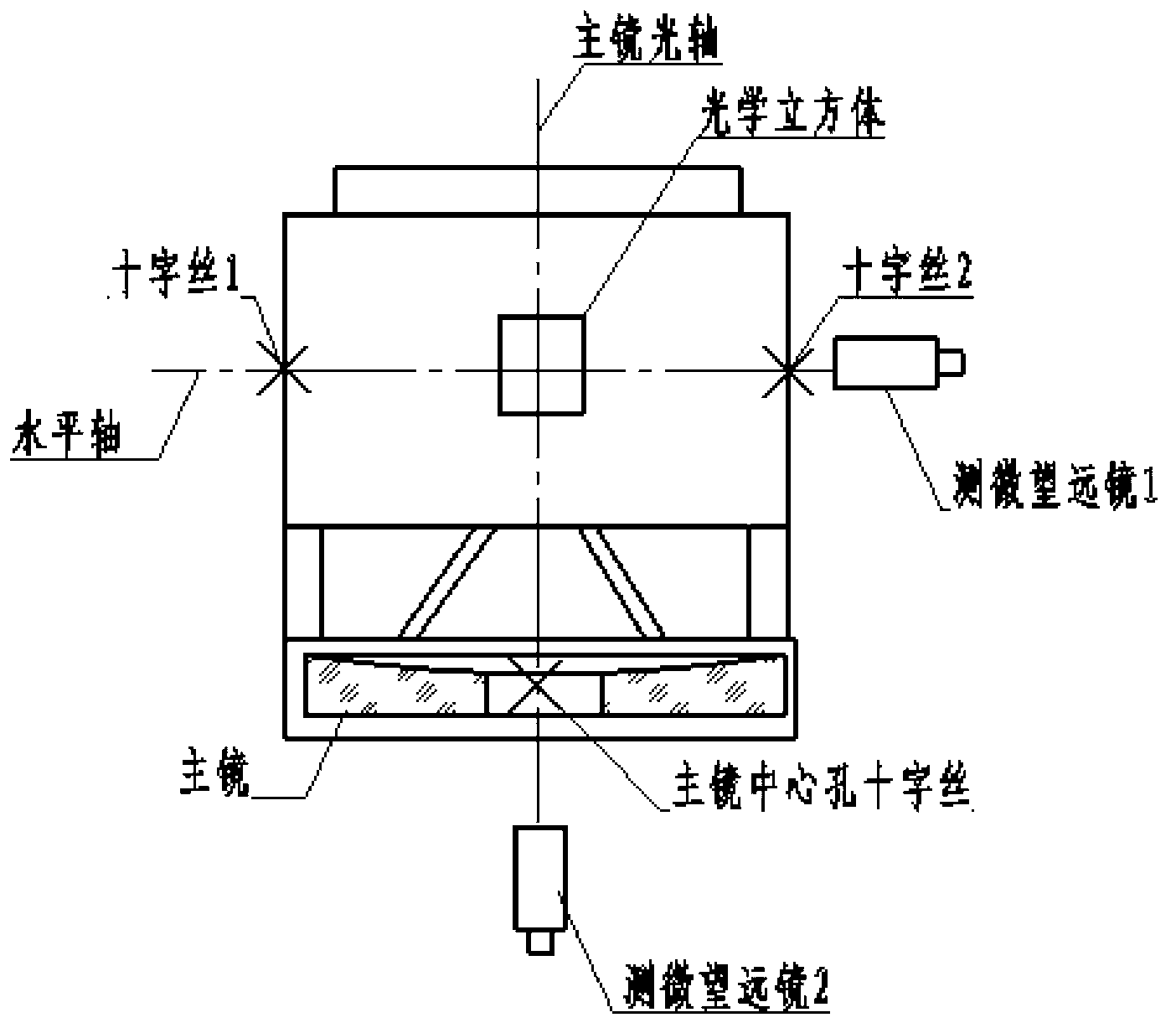

[0021] A method of using a laser tracker to adjust the optical axis of the primary mirror to be perpendicular to the horizontal axis, such as figure 1 , figure 2 As shown, the method is accomplished through the following steps:

[0022] (1) Set up the laser tracker. The laser tracker should be erected at a position where the horizontal axis and the primary mirror can be measured at the same time, and the laser tracker should be stable and cannot rotate with the horizontal axis.

[0023] (2) Fix the two target balls of the laser tracker at different positions on the horizontal axis, and the two-axis head of the horizontal axis is the most suitable, that is, it is suitable for fixing the target ball and also suitable for observing the target ball.

[0024] (3) Rotate the horizontal axis to drive the target ball, and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com