Measuring method for damage layer thickness of optical material subsurface

A technology of subsurface damage and optical materials, which is applied in measurement devices, preparation of test samples, instruments, etc., can solve the problem that the test accuracy is greatly affected, the experimental results are greatly affected, and the test accuracy of chemical etching solution differential corrosion method is not easy. Guarantee and other issues, to achieve the effect of low test cost, simple sample preparation process and suitable for large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

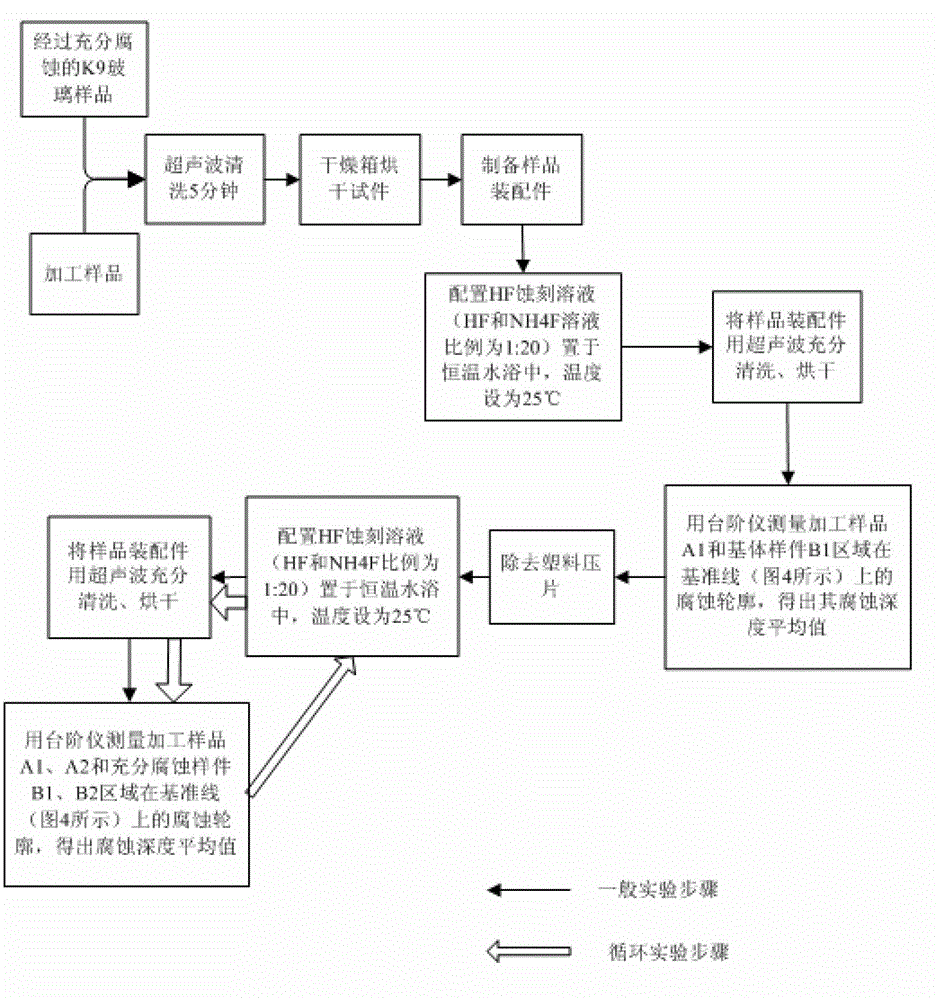

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] A method for measuring the thickness of a subsurface damaged layer of a hard and brittle optical material, comprising the steps of:

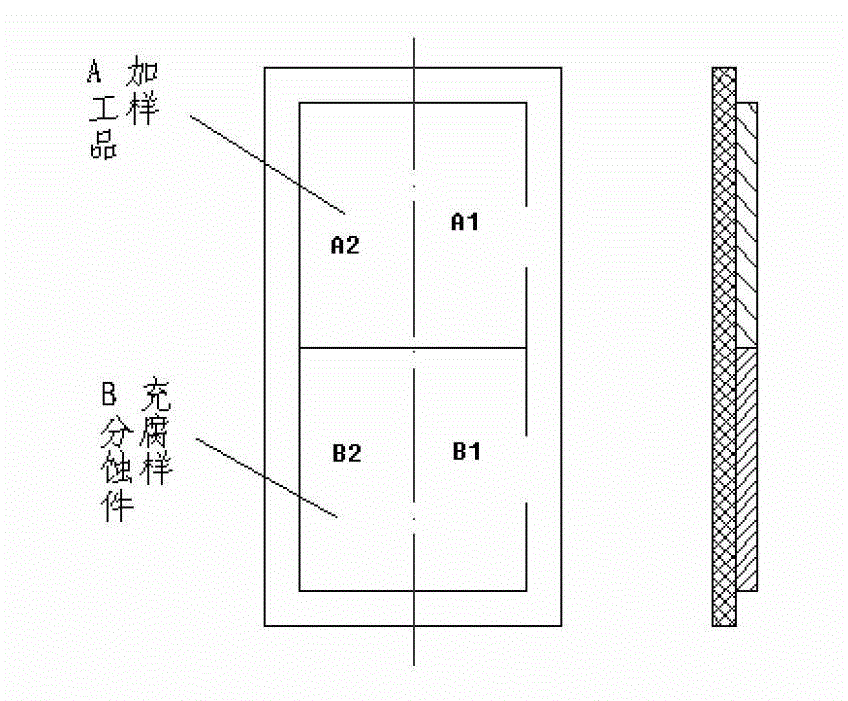

[0032] (1) Configure the chemical etching solution, and place the container containing the chemical etching solution in a constant temperature environment; place the substrate sample in the etching solution for no less than 2 hours to ensure that the subsurface damage layer has been completely removed, and obtain the results for comparison The substrate sample used;

[0033] (2) Put the processed sample to be tested with the same length and width and the substrate sample that has been fully corroded in the first step into the ultrasonic cleaning machine for cleaning at the same time or separately, take it out, and put it in a drying oven for drying;

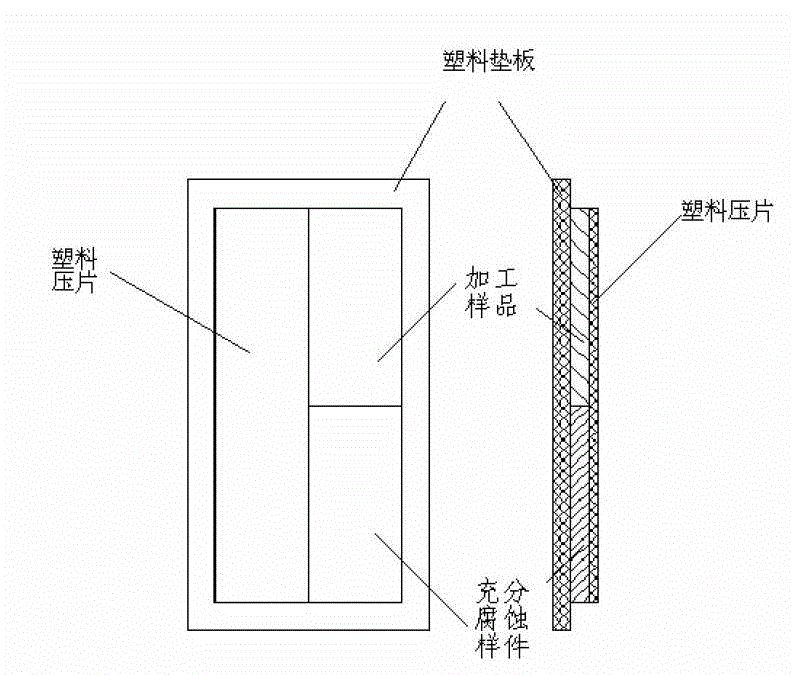

[0034] (3) Prepare the sample assembly; attach the cleaned and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com