A method for testing the resistance of the diffused layer of a finished battery sheet

A battery sheet and diffusion layer technology, applied in the direction of measuring resistance/reactance/impedance, measuring electrical variables, measuring devices, etc., can solve the problems that the resistance of the diffusion layer cannot be tested, the diffusion cannot be determined, and the sheet resistance cannot be known, etc., to increase The effect of testing costs, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] A method for testing the resistance of the diffusion layer of a finished battery sheet of the present invention is described in detail below in conjunction with preferred specific implementation examples, which mainly includes the following specific steps:

[0022] (1) Take 5 groups of silicon wafers, 5 pieces in each group, clean and texture according to the conventional battery process.

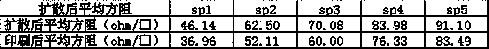

[0023] (2) Put 5 groups of silicon wafers into the tubular diffusion furnace, and carry out phosphorus diffusion according to the target values: 50, 60, 70, 80, 90 ohm / □ respectively.

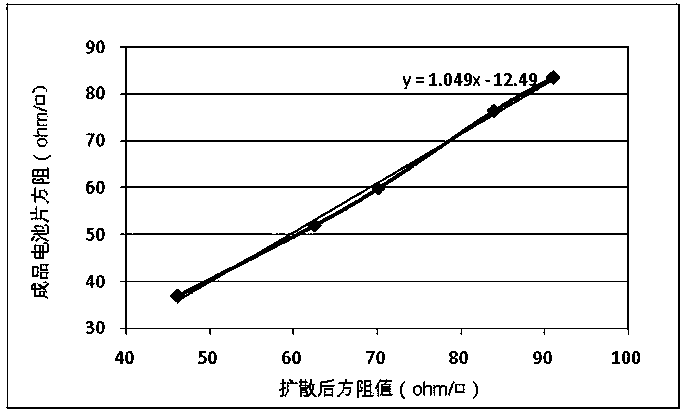

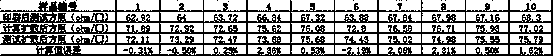

[0024] (3) Select 5 points evenly on the silicon wafer according to the same pattern, and use a four-probe resistivity tester to test the sheet resistance of the N-type layer after diffusion. The test results are listed in Table 1 below.

[0025] (4) Etch, coat, print electrodes and sinter ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com