Photosensitive resin composition, method of producing cured film, cured film, organic el display device, and liquid crystal display device

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition to achieve the effects of high chemical resistance, small loss of transparency, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

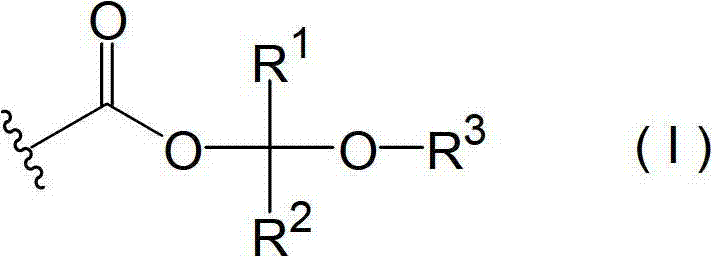

[0521] Preparation method of photosensitive resin composition

[0522] Component A to component C and (component D) essential components of a solvent are mixed in a predetermined ratio by any method, stirred and dissolved, and a photosensitive resin composition is prepared. For example, the photosensitive resin composition may be prepared by mixing component A, component B, or component C in advance in a solvent (component D) after each of component A, component B, or component C is mixed at a predetermined ratio. The photosensitive resin composition prepared in this way can be used after filtering using a filter etc. with a pore diameter of about 0.1 micrometer.

[0523] Formation method of hardened film

[0524] Next, the formation method of the cured film of this invention is demonstrated.

[0525] The method for forming the cured film of the present invention is not particularly limited except for using the positive photosensitive resin composition of the present inventi...

example 1~ example 11、 example 66 and example 67 and comparative example 1~ comparative example 4

[0620] (1) Preparation of photosensitive resin composition

[0621] After mixing the components shown in the following Table 3 to prepare a uniform solution, it was filtered using a filter made of polytetrafluoroethylene with a pore size of 0.1 μm, and Examples 1 to 11, Examples 66 and 67, and The solution of the photosensitive resin composition of Comparative Example 1-Comparative Example 4.

example 12~ example 28 and comparative example 7~ comparative example 14

[0667] (1) Preparation of photosensitive resin composition

[0668] After mixing the components shown in the following Table 4 to prepare a uniform solution, it was filtered using a filter made of polytetrafluoroethylene having a pore size of 0.1 μm to prepare Examples 12 to 28 and Comparative Examples 7 to Comparative Examples, respectively. 14 solution of the photosensitive resin composition. In addition, the unit of the addition amount in Table 4 is a mass part, and a ratio is a mass basis.

[0669]

[0670]

[0671]

[0672]

[0673] In addition, the abbreviations in Table 4 other than the polymer and the photoacid generator are as follows.

[0674] C'1: Duranate 17B-60PX (manufactured by Asahi Kasei Chemical Co., Ltd.)

[0675] C'2: Duranate (Duranate) 17B-60P (manufactured by Asahi Kasei Chemical Co., Ltd.)

[0676] In addition, C'1 and C'2 are blocked isocyanate compounds whose parent structure is a biuret structure and whose end-blocking structure is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com