Method for simulating and optimizing aluminum gate CMP (Chemical Mechanical Polishing) cooperative computing model

A technology of calculation model and simulation method, applied in calculation, instrument, electrical and digital data processing, etc., can solve the problems such as huge difference in characteristic curve of reaction process characteristic grinding rate, low efficiency, and inability to guarantee accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

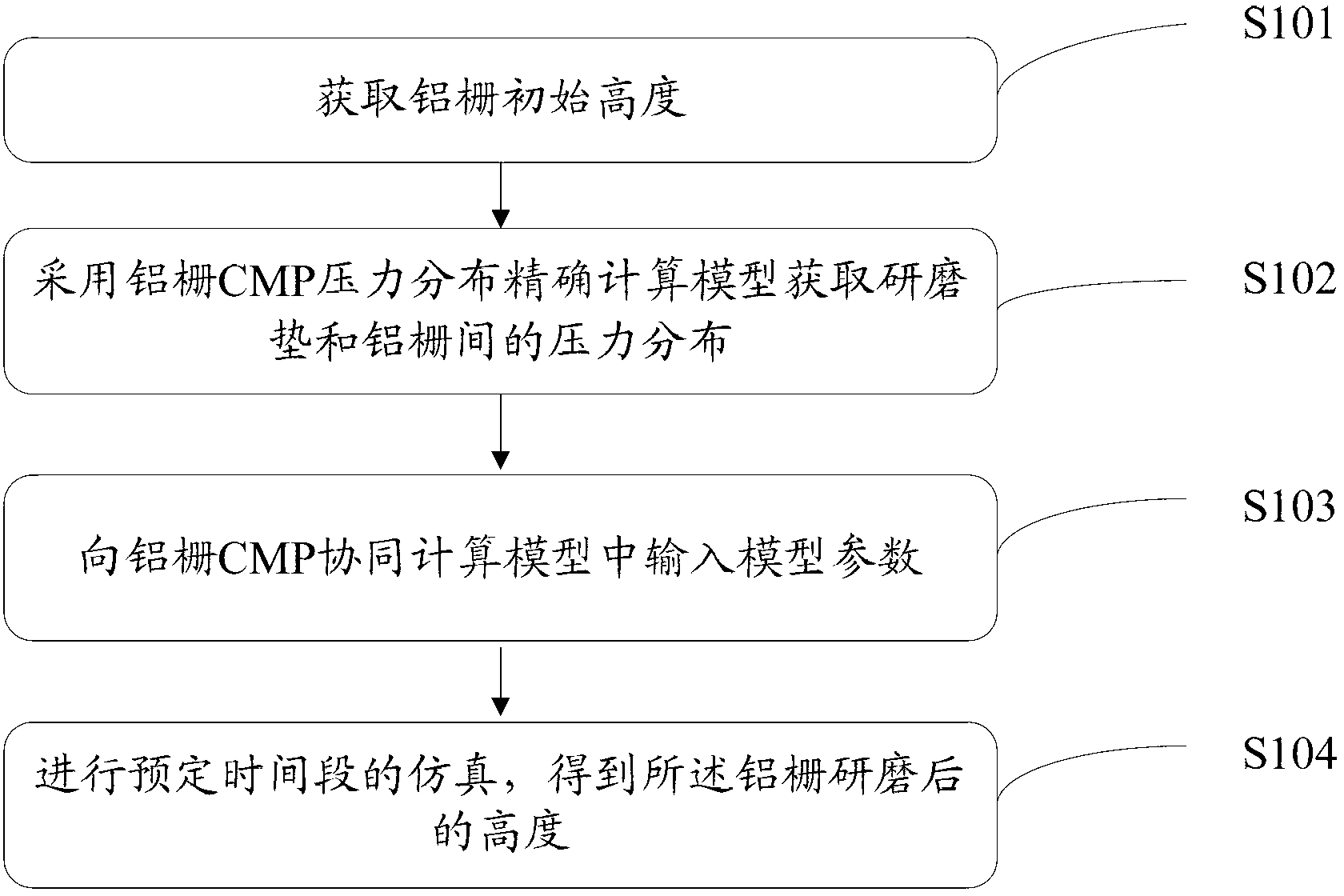

[0075] combine figure 1 Embodiment 1 of the simulation method of the present invention is described in detail.

[0076] figure 1 It is a flowchart of Embodiment 1 of the simulation method of the present invention, and the method includes the following steps:

[0077] S101. Obtain the initial height of the aluminum grid:

[0078] The initial surface height of the aluminum grid is obtained by using a general model in the field, that is, the surface height of the aluminum grid before grinding, and then the initial surface height is obtained by the aluminum grid CMP collaborative calculation model.

[0079] The aluminum grid CMP collaborative calculation model is:

[0080] MRR ( x , y , t ) = M ρ 0 ( k 60 ...

Embodiment 2

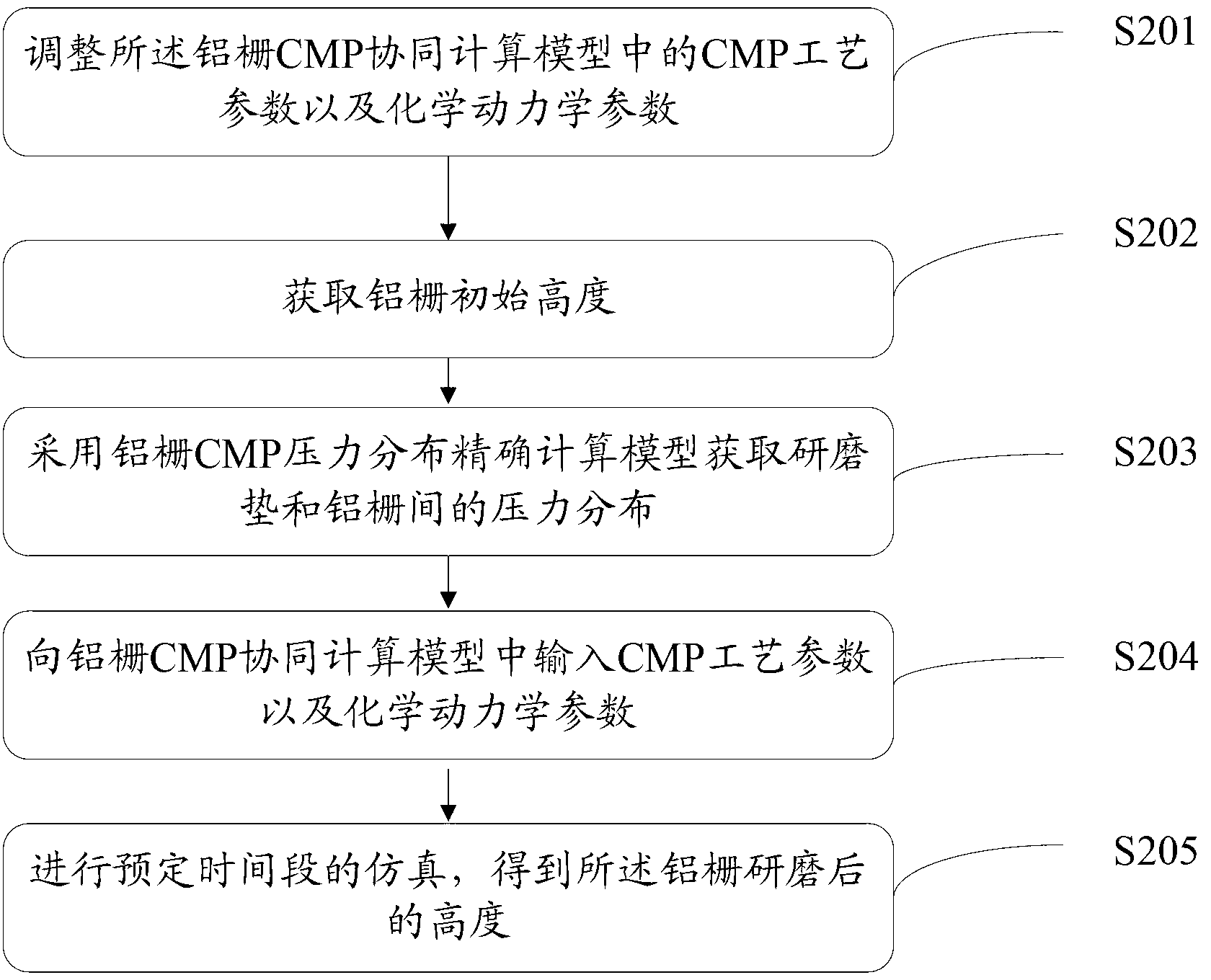

[0133] The adjustment of the CMP process parameters and the chemical kinetic parameters can be done before the model acquires the initial height of the aluminum grid, or before inputting the model parameters to the aluminum grid CMP collaborative calculation model. figure 2 It is shown that adjusting the simulation parameters is placed before obtaining the initial height of the aluminum grid.

[0134] S201. Adjust the CMP process parameters and chemical kinetic parameters of the aluminum gate CMP collaborative calculation model:

[0135] Technicians can adjust CMP process parameters and chemical kinetic parameters based on the simulation results. And because the establishment of the chemical reaction kinetic model in the aluminum grid CMP collaborative calculation model is obtained from the perspective of reaction mechanism, the CMP process parameters, chemical kinetic parameters and variables in the chemical reaction kinetic model are clearly defined Physical meaning, such ...

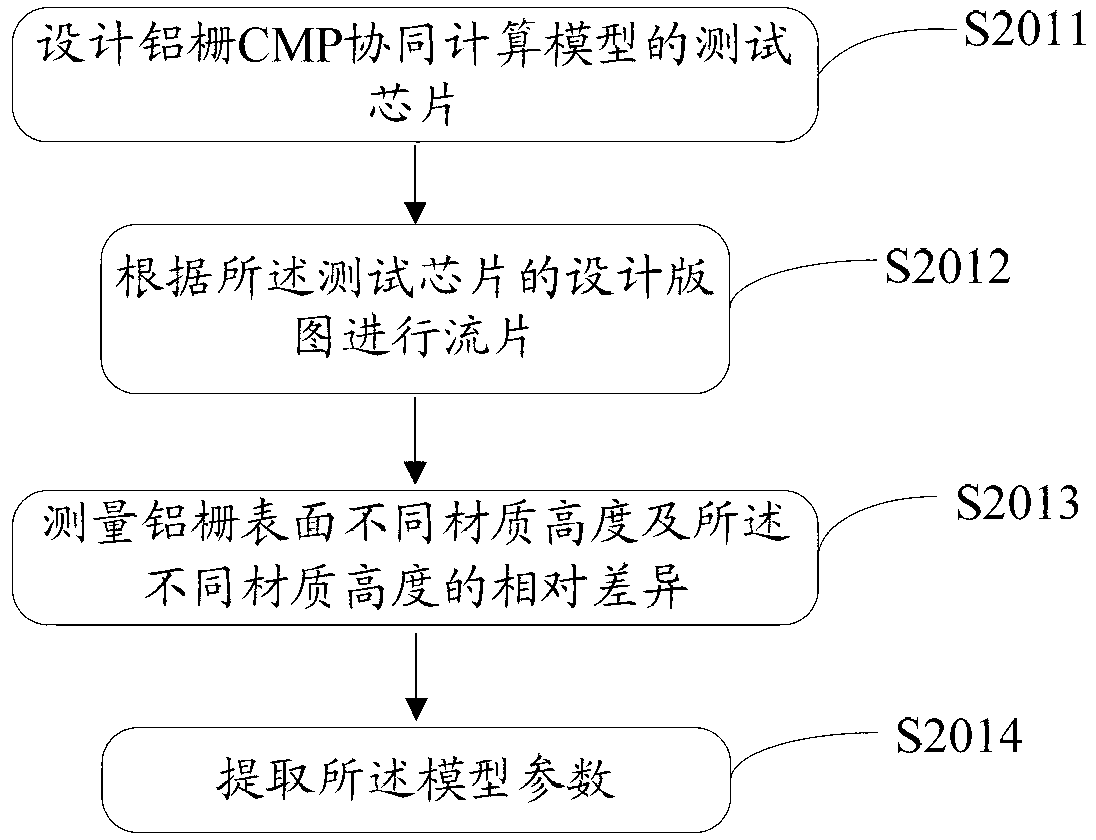

Embodiment 3

[0156] After the grinding height of the aluminum grid is obtained in the first or second embodiment, layout parasitic parameter extraction software can also be used to extract process parasitic parameters such as resistance or capacitance. see Figure 4 . Figure 4 The flow of the simulation method in the third embodiment of the present invention is shown, and the simulation method is an improvement on the basis of the second embodiment.

[0157] Steps S401-S405 are the same as steps S201-S205 in Embodiment 2. For detailed information, refer to Embodiment 2. For the sake of brevity, no detailed description is given.

[0158] S406. Extraction process parasitic parameters:

[0159] Based on the prediction of the surface height of the aluminum grid after grinding, the layout parasitic parameter extraction software is used to replace the fixed aluminum grid thickness with the simulated thickness that varies with different regions, so that more accurate process parasitic paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com