PID (potential induced degradation) resistible solar cell passivated antireflective film

A solar cell, passivation reduction technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as PID failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

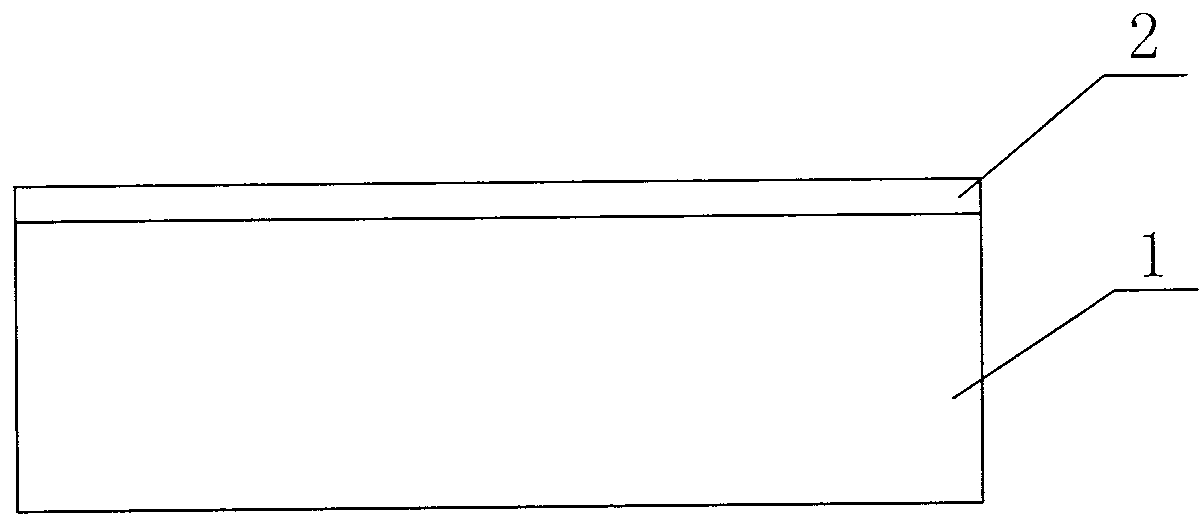

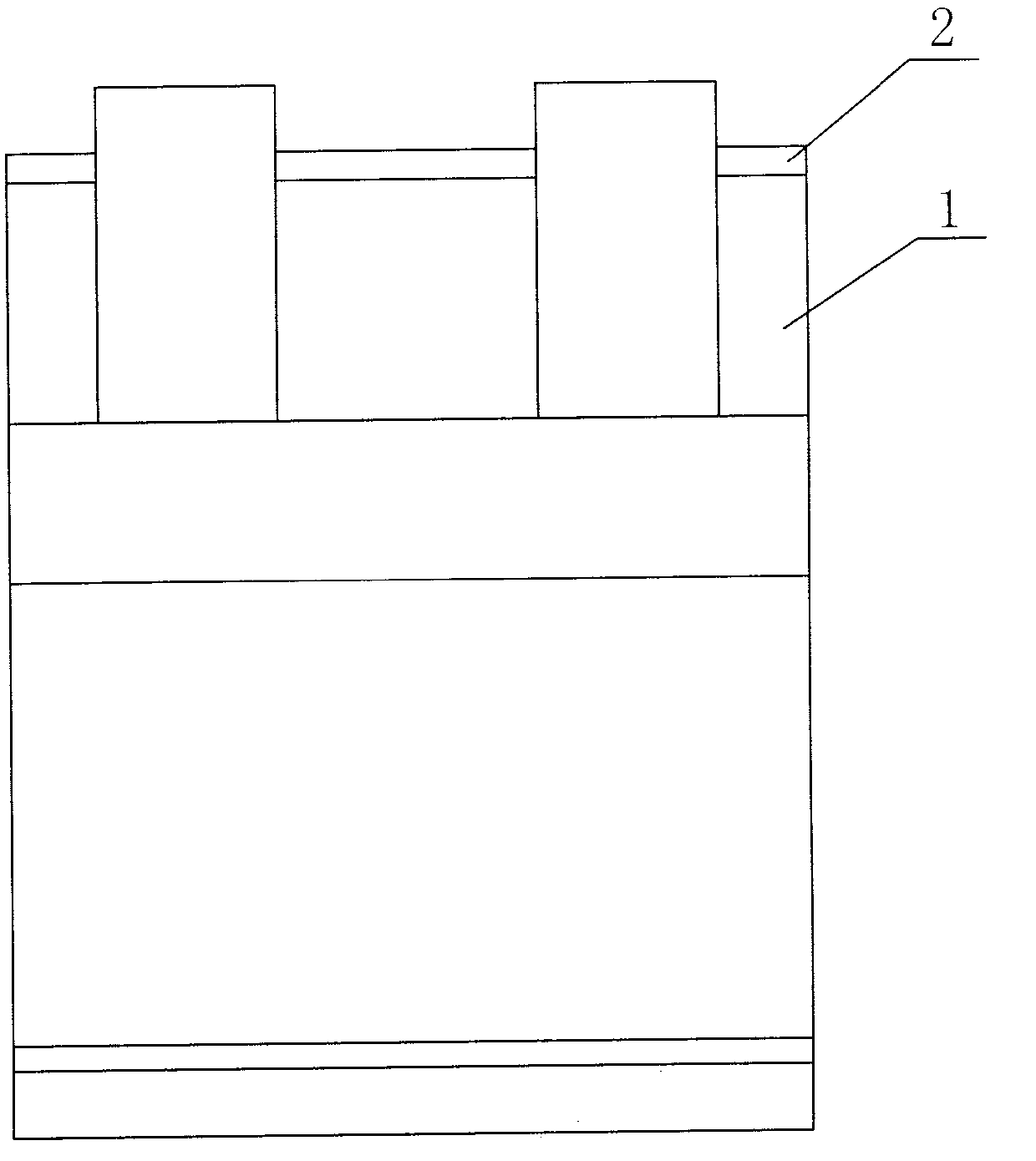

[0019] like figure 1 As shown, a solar cell passivation anti-reflection film capable of resisting the PID effect, the bottom layer of the passivation anti-reflection film is a passivation anti-reflection layer 1, made of SiNx material, with a refractive index of 2.0-2.1 and a thickness of 70 -80nm; The top layer of the passivation anti-reflection film is the conductive layer 2, that is, the amorphous silicon layer (a:Si), with a thickness of 3-10nm.

[0020] The preparation method of the solar cell passivation anti-reflection film comprises the following steps:

[0021] a. Pretreatment of the original silicon wafer, the pretreatment includes the pre-cleaning, diffusion and post-cleaning processes of the traditional battery process;

[0022] b. Use PECVD method to coat the anti-reflection film on the diffusion surface. The bottom layer is a passivation anti-reflection layer SiNx with a refractive index of 2.0-2.1 and a thickness of 70-80nm; the top layer is a conductive laye...

Embodiment 2

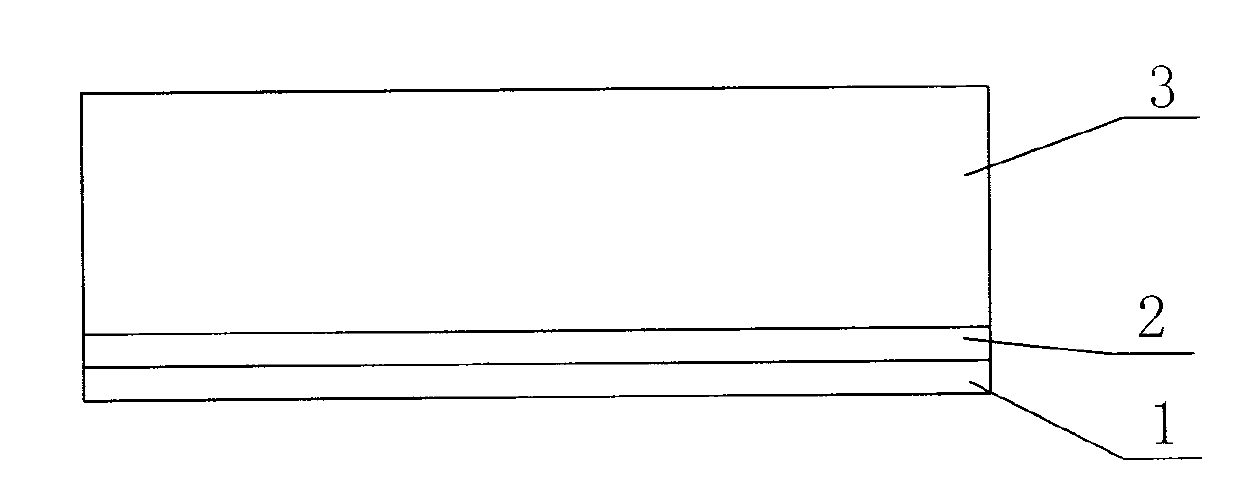

[0026] like image 3 As shown, a solar cell passivation antireflection film capable of resisting the PID effect, the bottom layer of the passivation antireflection film is a passivation layer 1, made of SiNx material, with a refractive index of 2.2-2.3 and a thickness of 9-11nm The middle layer of this passivation anti-reflection film is a conductive layer 2, i.e. an amorphous silicon layer (a: Si), with a thickness of 3-10nm; the top layer of this passivation anti-reflection film is an anti-reflection layer 3, which is made of SiNx material into, the refractive index is 2.0-2.1, and the thickness is 60-70nm.

[0027] The preparation method of the solar cell passivation anti-reflection film comprises the following steps:

[0028] a. Pretreatment of the original silicon wafer, the pretreatment includes the pre-cleaning, diffusion and post-cleaning processes of the traditional battery process;

[0029] b. Anti-reflective coating is plated on the diffusion surface by PECVD meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com