Photovoltaic assembly quality automatic detection method

A photovoltaic module, automatic detection technology, applied in the direction of optical testing flaws/defects, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve the problems of poor quantification, single/polycrystalline cell lattice differences, and uncertain results and other issues, to achieve the effect of reducing logistics costs, fast detection speed, and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

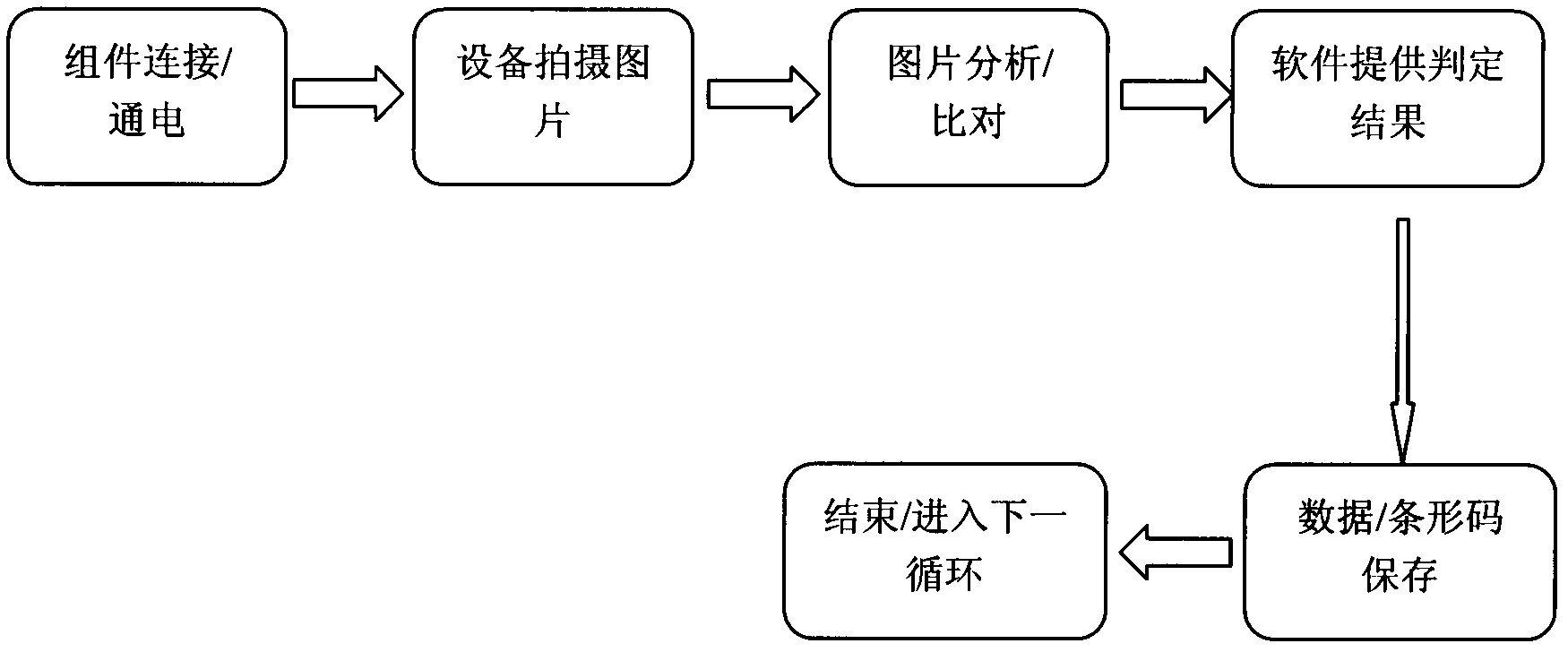

[0027] Such as figure 1 A photovoltaic module quality automatic detection method shown, the method steps are:

[0028] A) Component connection and energization: the automatic assembly line transports the components to be tested to the EL testing equipment, and connects and energizes with the EL testing equipment;

[0029] B) The equipment takes pictures: during the power-on process, the infrared camera works and shoots, and captures the pictures when the components are powered on;

[0030] C) Image analysis and comparison, the specified software in the EL testing equipment utilizes image recognition and analysis theory to pre-build a photovoltai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com