Wide-frequency-band multi-direction vibration energy harvester

A vibration energy harvesting and wide-band technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Directional vibration energy and other issues, to achieve the effect of improving power generation capacity and conversion efficiency, and increasing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

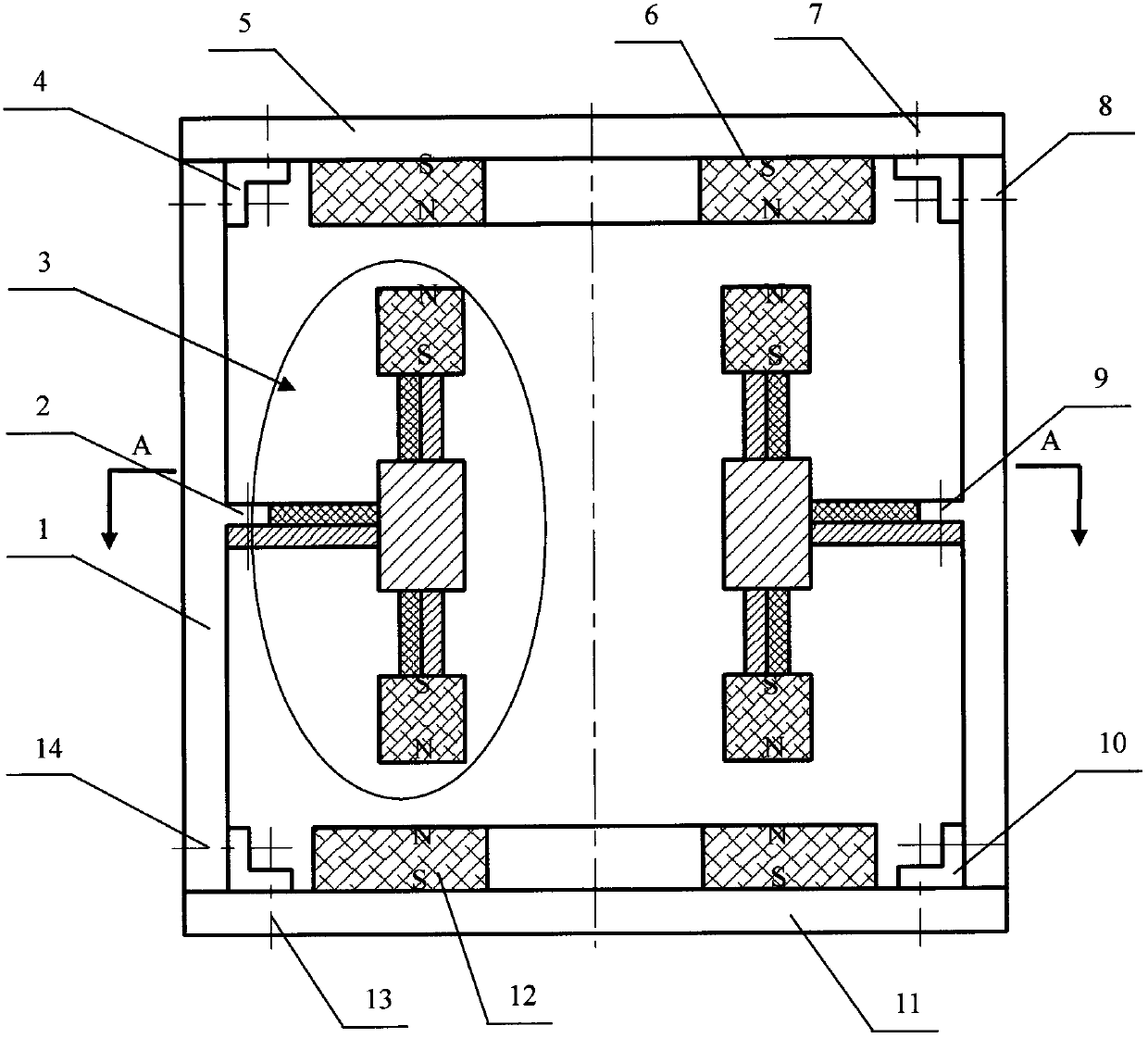

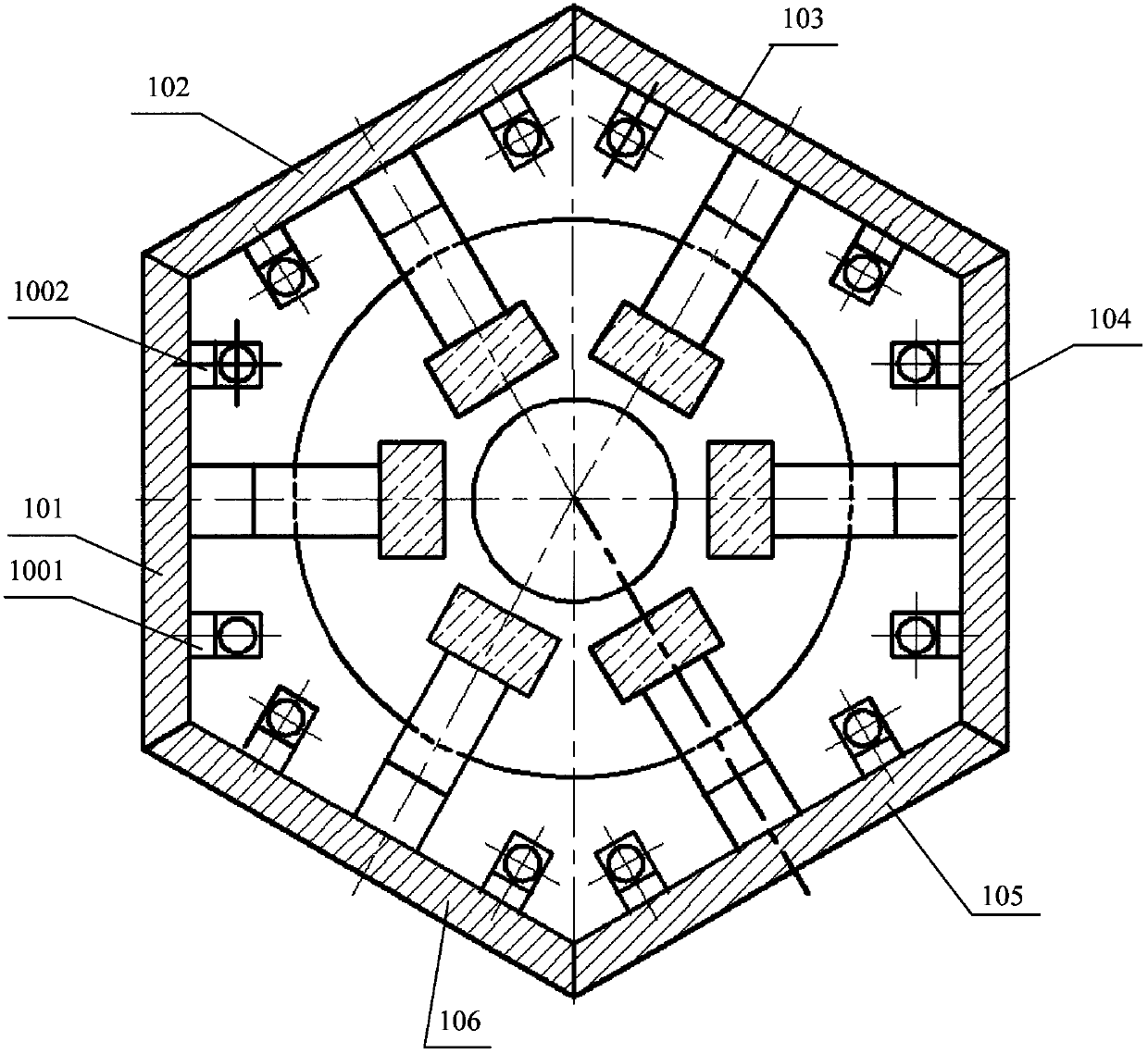

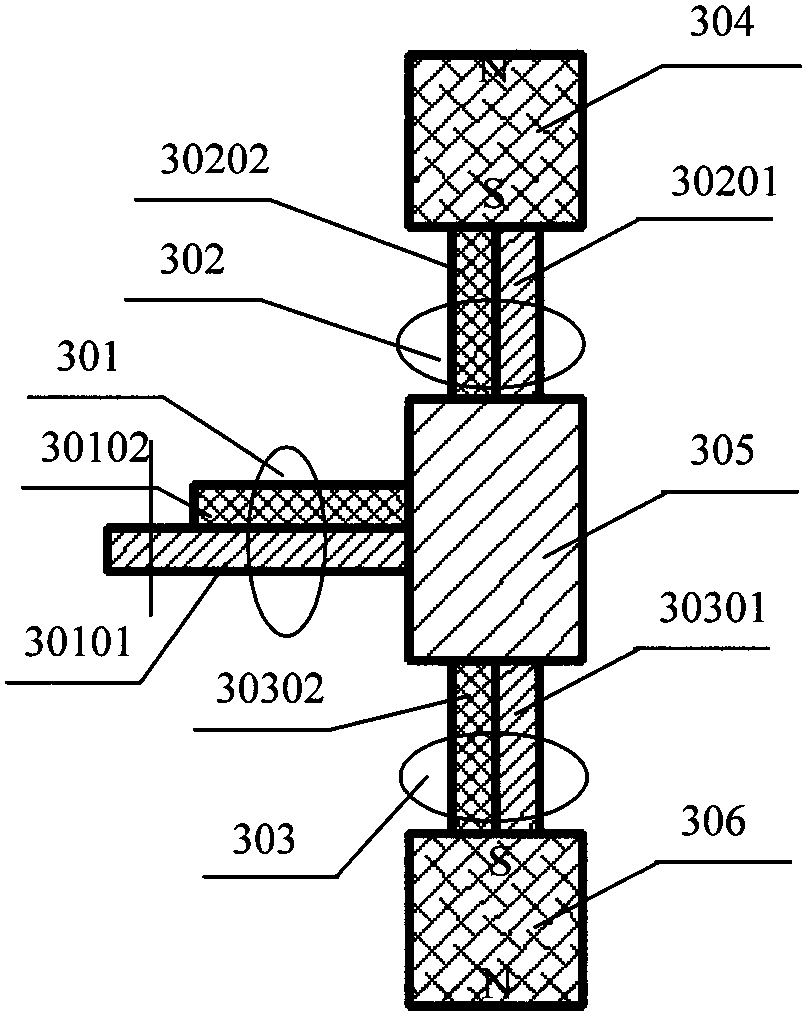

[0016] Such as figure 1 , 2 As shown, the housing 1 is composed of six metal plates 101, 102, 103, 104, 105, and 106 to form a hexahedron, and the angle between two adjacent metal plates is 120 degrees. The metal plates 101, 102, 103, 104, 105, 106 are respectively fixed by two right-angle fixing pieces 4 on the top and two right-angle fixing pieces 10 (1001, 1002) on the bottom and screws 7, 8, 13, 14 Between the upper cover plate 5 and the lower cover plate 11. The centers of the metal plates 101, 102, 103, 104, 105, and 106 are respectively provided with a connecting seat 2 for fixing the T-shaped piezoelectric vibrator 3, and the T-shaped piezoelectric vibrator 3 is fixed on the connecting seat 2 by screws 9; the T-shaped piezoelectric vibrator 3 is fixed on the connecting seat 2; The piezoelectric vibrator 3 is composed of a horizontal cantilever beam 301, two vertical cantilever beams 302, 303, two magnets 304, 306 and a metal block 305; the horizontal cantilever beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com