Printed circuit board with partial housing encapsulated in a pressure-resistant manner

A technology for circuit boards and circuit board assemblies, which is applied in the direction of assembling printed circuits, printed circuits, and printed circuits with electrical components, which can solve the problems of complex manufacturing processes, component failures, and delayed development processes in the potting section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

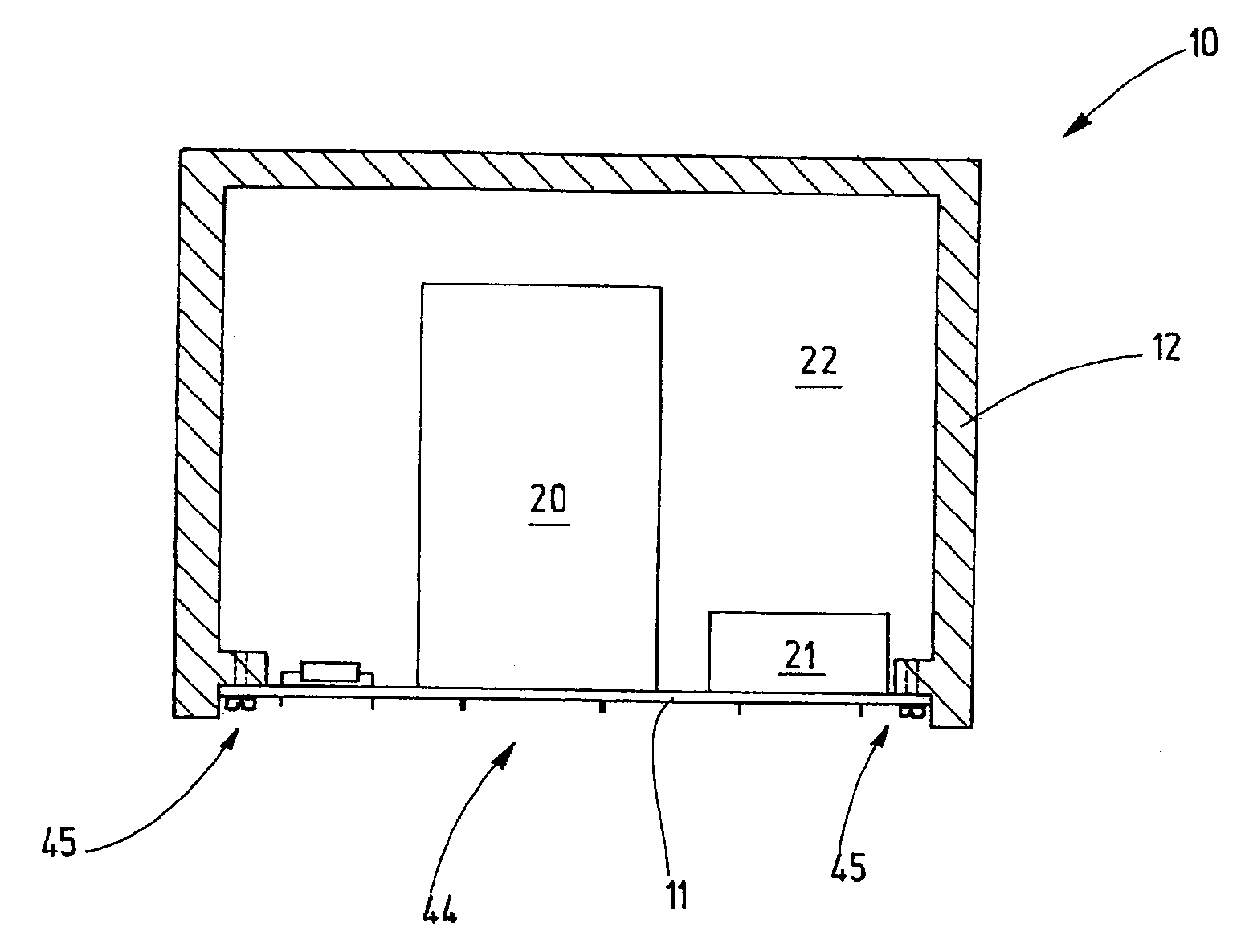

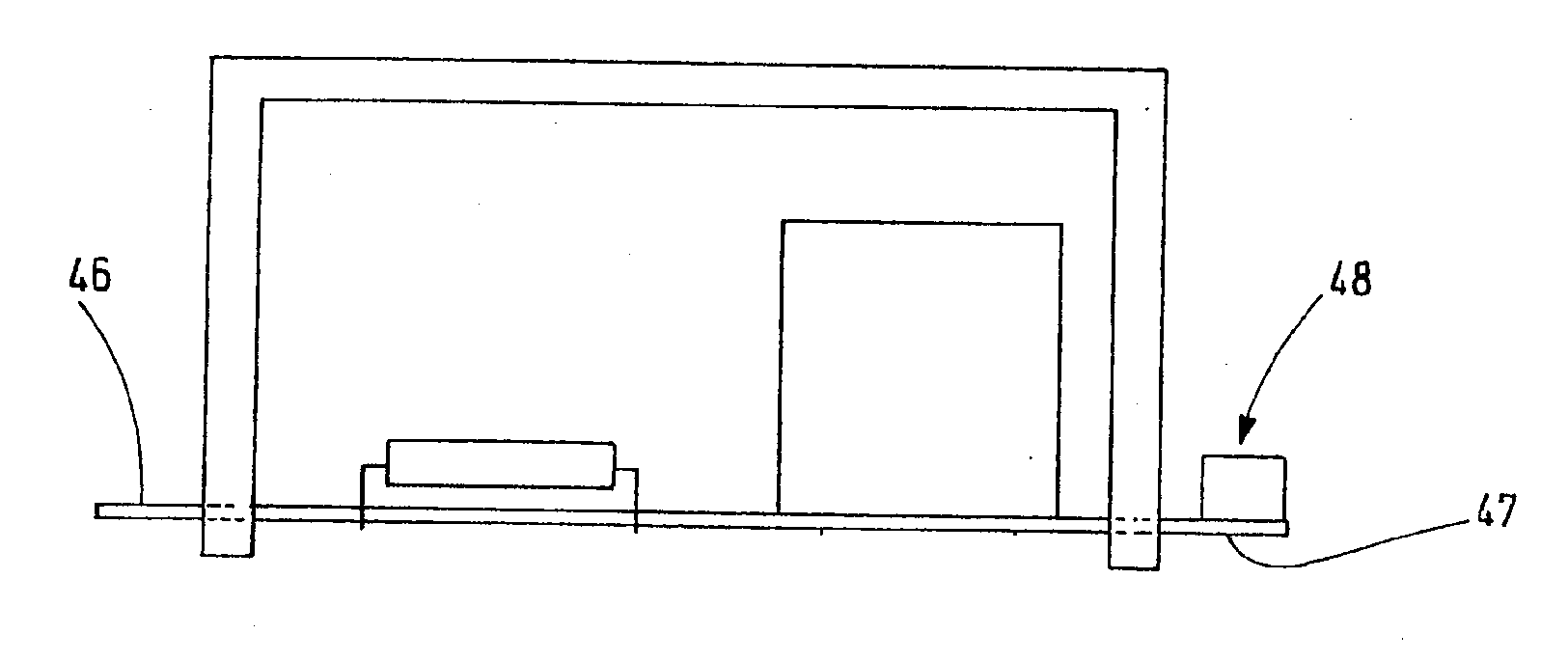

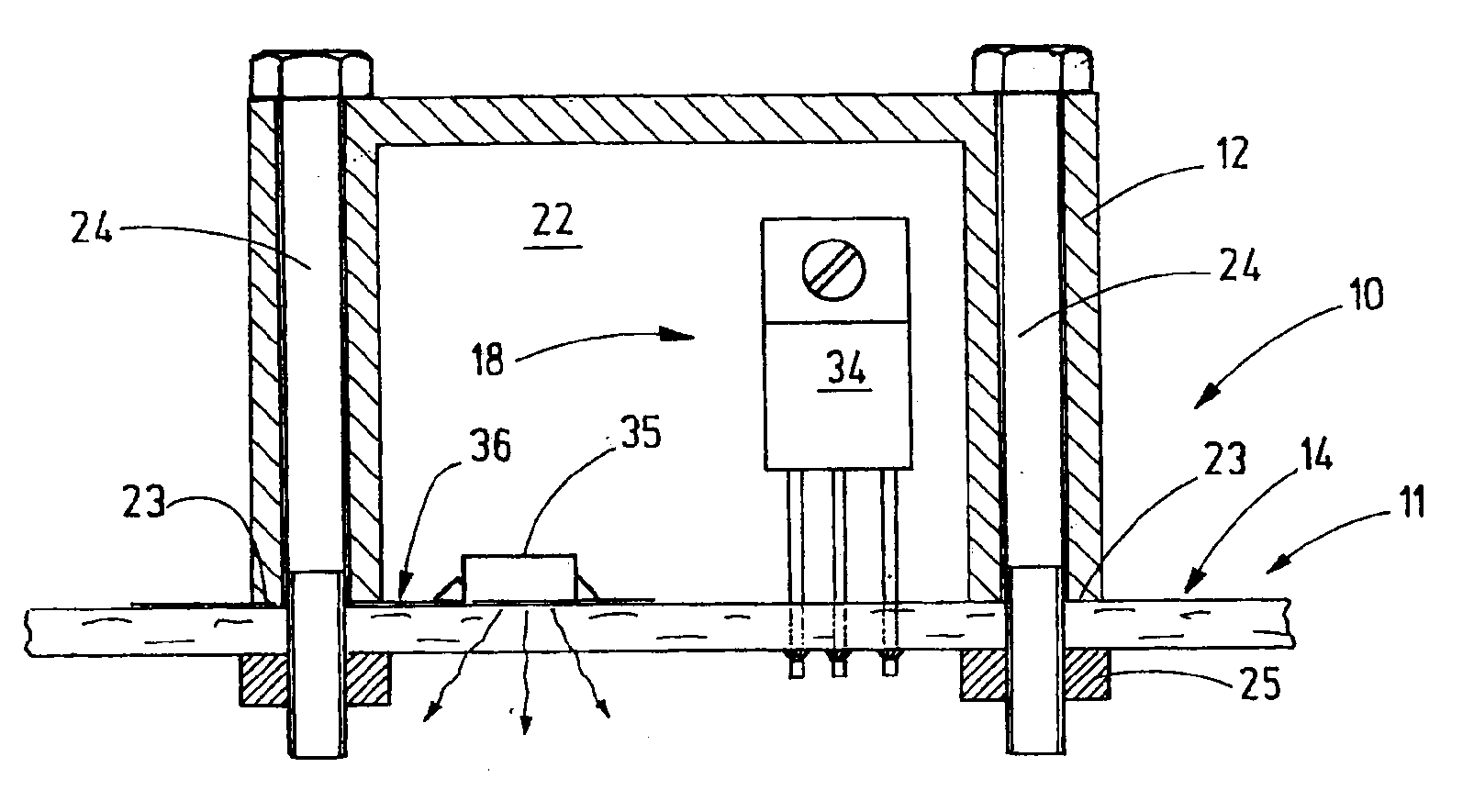

[0029] exist figure 1 A circuit board assembly 10 is illustrated in , to which a circuit board 11 and at least one housing part 12 belong. The circuit board 11 has a plate-shaped carrier (Traeger) 13 with a first flat side 14 and a second flat side 15 (see figure 2 ). The circuit board has columns of conductors. It is arranged, for example, in the carrier 13 . Alternatively or additionally, a conductor row 16 can be arranged on at least one of the two flat sides 14 , 15 . Further conductor rows 17 can be arranged on the respective other flat side.

[0030] Conductor row 16 or 17 forms a non-intrinsically safe line with at least one electrical component 18 . Electrical components 18 may be energy storage components (such as inductors or capacitors), transformers, consumer components (such as resistors), electronic components (such as diodes, Z diodes, transistors, integrated circuits), optoelectronic components (such as light-emitting diodes tube), connecting terminal as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com