Diesel engine tail gas two-stage water-air separation and cooling washing box for explosive atmosphere

A water-gas separation and water-gas separator technology, applied in exhaust devices, mechanical equipment, engine components, etc., can solve the problems of reducing the service life of the equipment, difficult to clean, blocking the exhaust channel, etc., to reduce consumption and complete separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with embodiments:

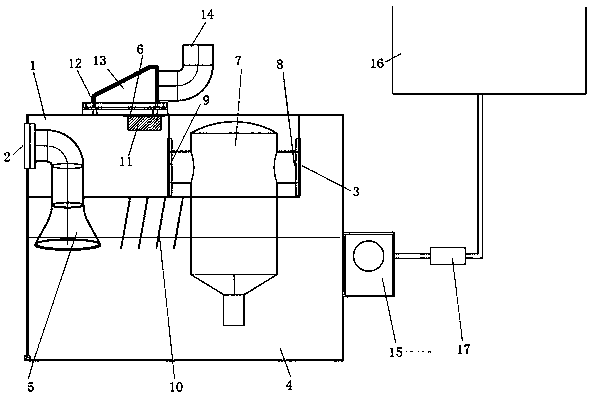

[0023] Such as figure 1 As shown, the two-stage water-gas separation cooling washing tank for diesel engine tail gas for explosive environments includes a washing tank 1. The washing tank 1 is divided into upper and lower parts. The lower part of the washing tank 1 is provided with cooling water 4, and a communication port is passed between the upper and lower parts. 3 Connected. An exhaust gas inlet is arranged on the upper side wall of the washing tank 1, an exhaust pipe 5 is arranged in the exhaust gas inlet 2, and a nozzle is arranged at the outlet of the drain pipe 5. The nozzle of the drain pipe 5 leads to 5-10mm below the liquid surface of the cooling water 4, A gas outlet 6 is provided at the top of the upper part of the washing tank 1. The washing tank 1 is also provided with a two-stage water-gas separator 7. The air inlet 8 and the air outlet 9 at the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com