Machine tool for machining inner bore and end surfaces of flange of shield tunneling machine

A technology of shield machine and inner hole, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., which can solve the problems of fixed processing range, large machine tool volume, and large cost investment, so as to reduce input cost and maintain Cost, simple structure of machine tool, and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

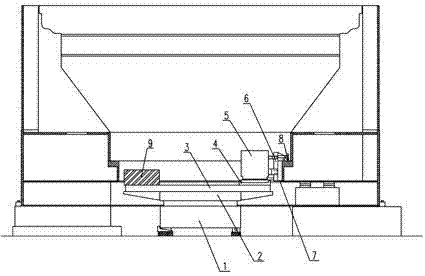

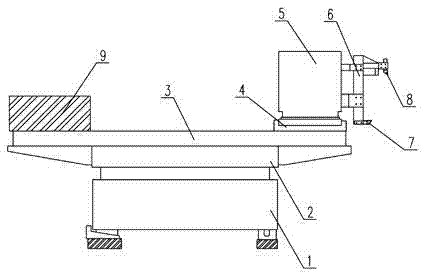

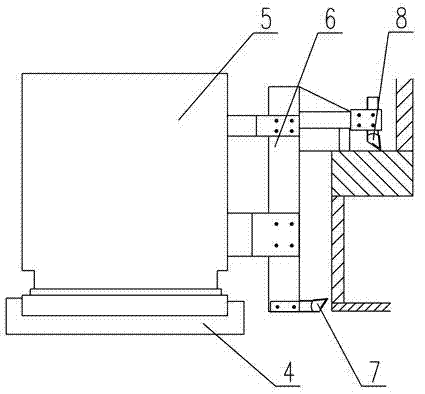

[0011] The machine tool for processing the inner hole and end face of the flange of the shield machine according to the present invention includes a base 1 at the bottom of the machine tool, the upper end of the base 1 is connected with a turntable 2, and the turntable 2 rotates around its axis on the base 1. And the turntable 2 is fixed in the cavity of the inner hole of the processing object, the upper end of the turntable 2 is fixed with an auxiliary platform 3, the upper surface of the auxiliary platform 3 has a guide rail along the diameter direction of the turntable, and there is a walking block 4 moving along the guide rail on the guide rail. On the block 4 there is an elevating device 5 vertically vertical to the turntable 2, and there is a knife rest 6 for fixedly installing the cutter. On the other hand, the cutting tool includes a horizontal cutting tool 7 for processing the inner hole and a longitudinal cutting tool 8 for processing the end surface.

[0012] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com